Tunnel drying system and drying method

A drying system and tunnel technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of high pollution, low heat energy utilization rate, and large environmental impact, so as to reduce energy consumption, save energy, improve The effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

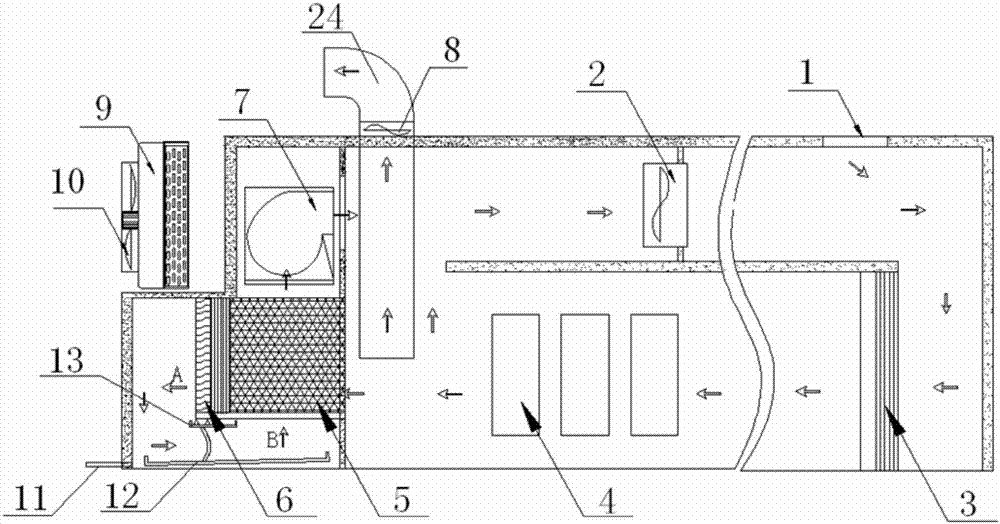

[0056] Tunnel drying system, including circulating air duct, circulating fan 2 located in the circulating air duct, dehumidifying fan 7 located in the circulating air duct, full heat exchange core 5 located in the circulating air duct and heat pump unit, multiple sets of circulating fans can be arranged side by side , the present invention can use one or more sets of heat pump units according to the situation.

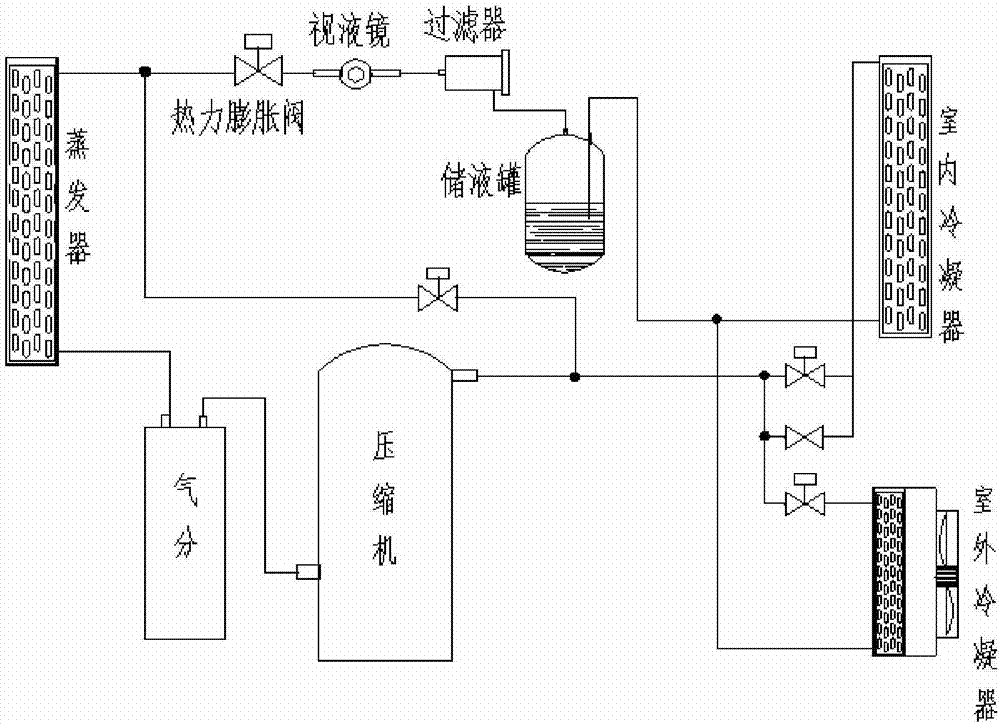

[0057] The heat pump unit includes a compressor, an indoor condenser 3, a throttling device, and an evaporator 6. The outlet of the compressor is connected to the inlet of the compressor through the indoor condenser 3, the throttling device, and the evaporator 6 in sequence. Both the indoor condenser 3 and the evaporator 6 are located in the circulating air duct.

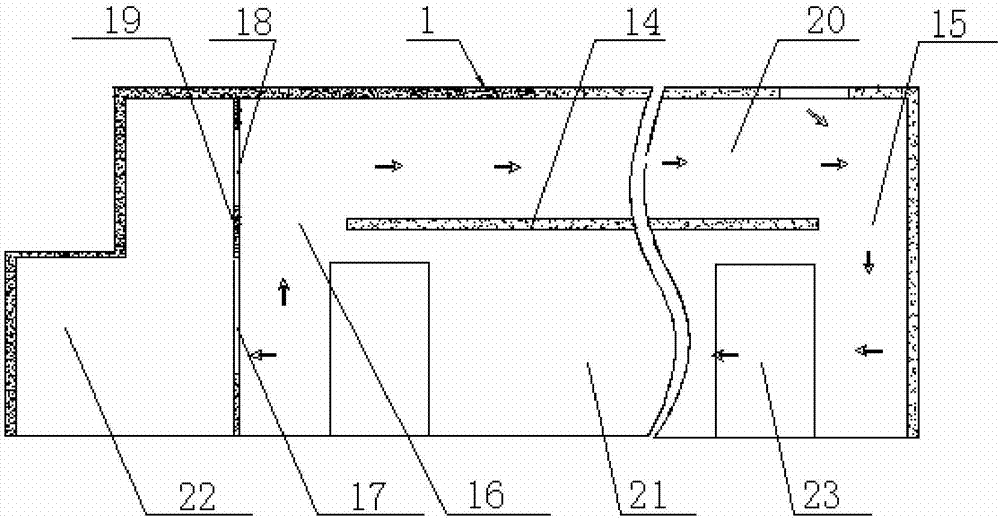

[0058] The circulating air duct is formed by separating the chamber body and several partitions, specifically, as figure 2 , the chamber body is divided into a first chamber body 22 and a second chamber bo...

Embodiment 2

[0070] On the basis of Embodiment 1, preferably, the tunnel drying system further includes an exhaust pipeline 24 equipped with a negative pressure fan 8; the inlet of the exhaust pipeline 24 is located between the material to be dried 4 and the Between the air inlets of the air duct A of the total heat exchange core 5 , the outlet of the air exhaust pipeline 24 is located outside the circulating air duct. The entrance position of the air exhaust pipeline 24 is selected because the air circulation in the circulating air duct is blown from the condenser side to the evaporation side. After the relatively dry air on the condensation side reaches the evaporation side, it becomes moisture with a high relative humidity, and the water vapor evaporated from the material will be absorbed in the middle. Therefore, the negative pressure fan 8 of the exhaust pipeline 24 not only pumps the most humid gas to the outside, but also makes the air pressure in the entire circulating air duct low...

Embodiment 3

[0073] On the basis of Embodiment 1 or 2, preferably, the heat pump unit further includes an outdoor condenser 9, the outdoor condenser 9 is installed outside the circulating air duct, and the indoor condenser 3 and the outdoor condenser 9 are connected in parallel . The heat pump unit also includes an outdoor fan 10 for cooling the outdoor condenser 9 .

[0074] In this way, step 3] of the control method of Embodiment 3 can still adopt the steps of Embodiment 1, and can also adopt the following steps: start the dehumidification fan and compressor, the indoor condenser and evaporator start to work, and the moisture in the air condenses into water droplets When the current "condensing side temperature" measured by the sensor reaches the "upper temperature limit of the current period", the compressor may not be turned off, but the outdoor condenser 9 and the outdoor fan 10 are started, that is, the outdoor condensing side is turned on immediately. The solenoid valve in the bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com