Automobile vibration fault detection system and detection data analysis method thereof

A technology for fault detection and data detection, which is used in vehicle testing, measuring devices, and machine/structural component testing. It can solve the problems of small processor data storage capacity, low data processing accuracy, and high processor energy consumption. , to achieve the effect of saving troubleshooting time, fast data processing, and large data storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

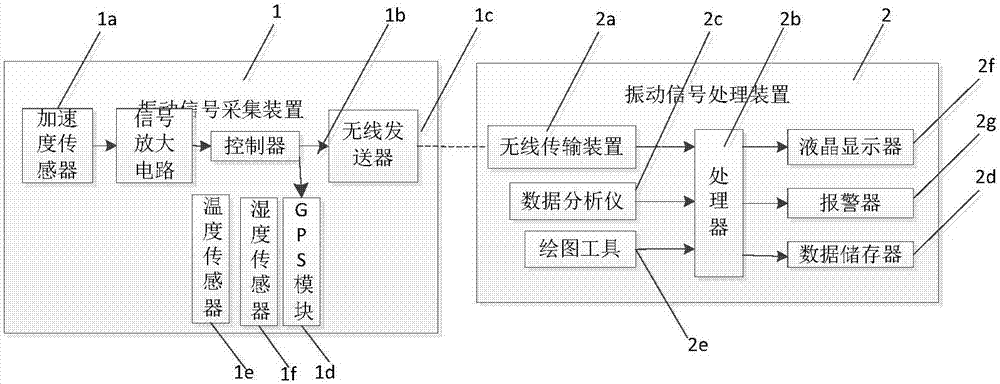

[0079] From figure 1 It can be seen that a vehicle vibration fault detection system is characterized in that: comprising a vibration signal acquisition device 1 and a vibration signal processing device 2;

[0080] Described vibration signal acquisition device 1 is arranged on the automobile, and described vibration signal acquisition device 1 comprises a plurality of acceleration sensors 1a, and described acceleration sensor 1a is connected with the vibration signal input end of controller 1b, and wirelessly connected to controller 1b The sending end is connected with a wireless transmitter 1c. Wherein each acceleration sensor 1a is arranged at different positions of the car, and is used for detecting vibration signals of different devices, such as car engine, car battery, car shaft and so on.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com