A method and system for detecting and diagnosing cracks and missing teeth of online woodworking band saw blades

A technology of fault detection and diagnosis method, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., which can solve problems such as affecting the personal safety of operators, crossing the range, and not easily seeing the band saw blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

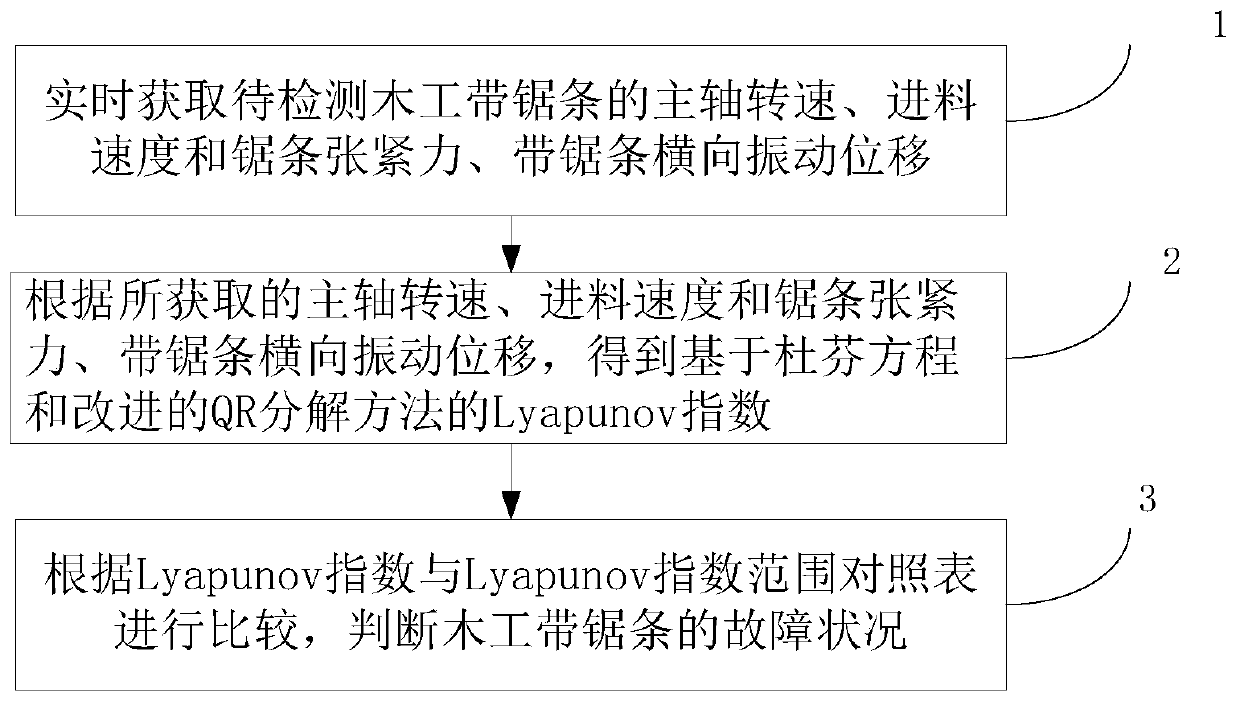

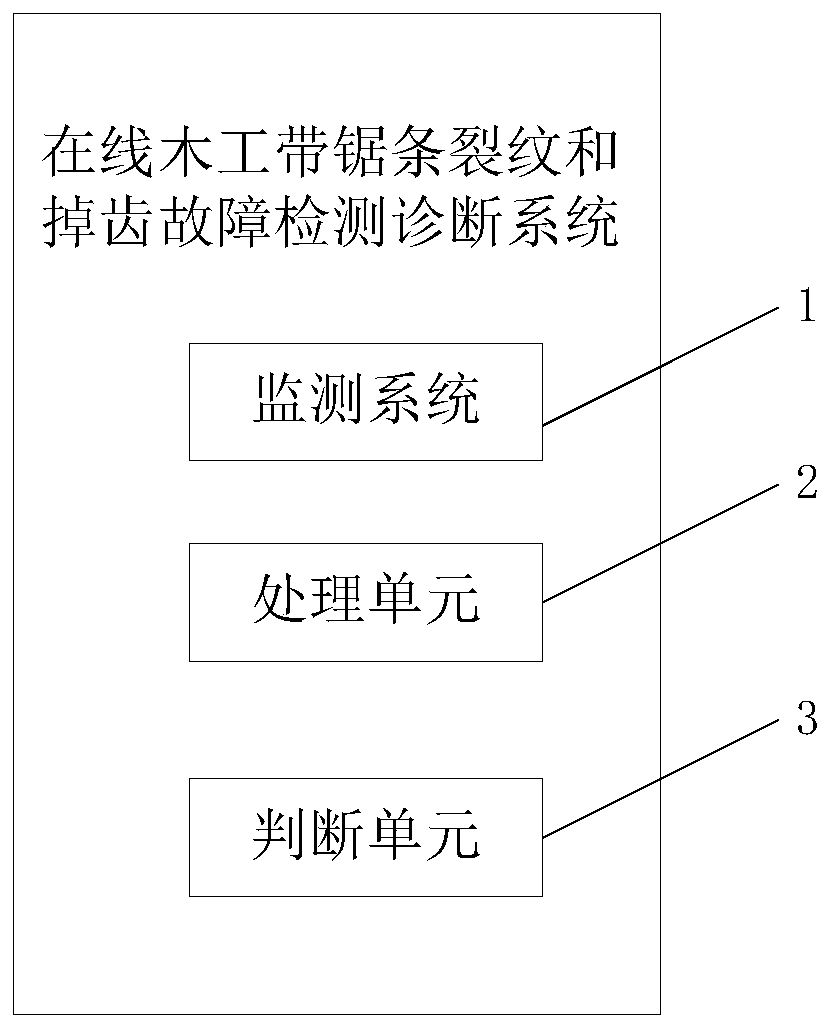

[0069] Such as figure 1 As shown, the present invention provides a method for detecting and diagnosing cracks and tooth loss faults of online woodworking band saw blades, including:

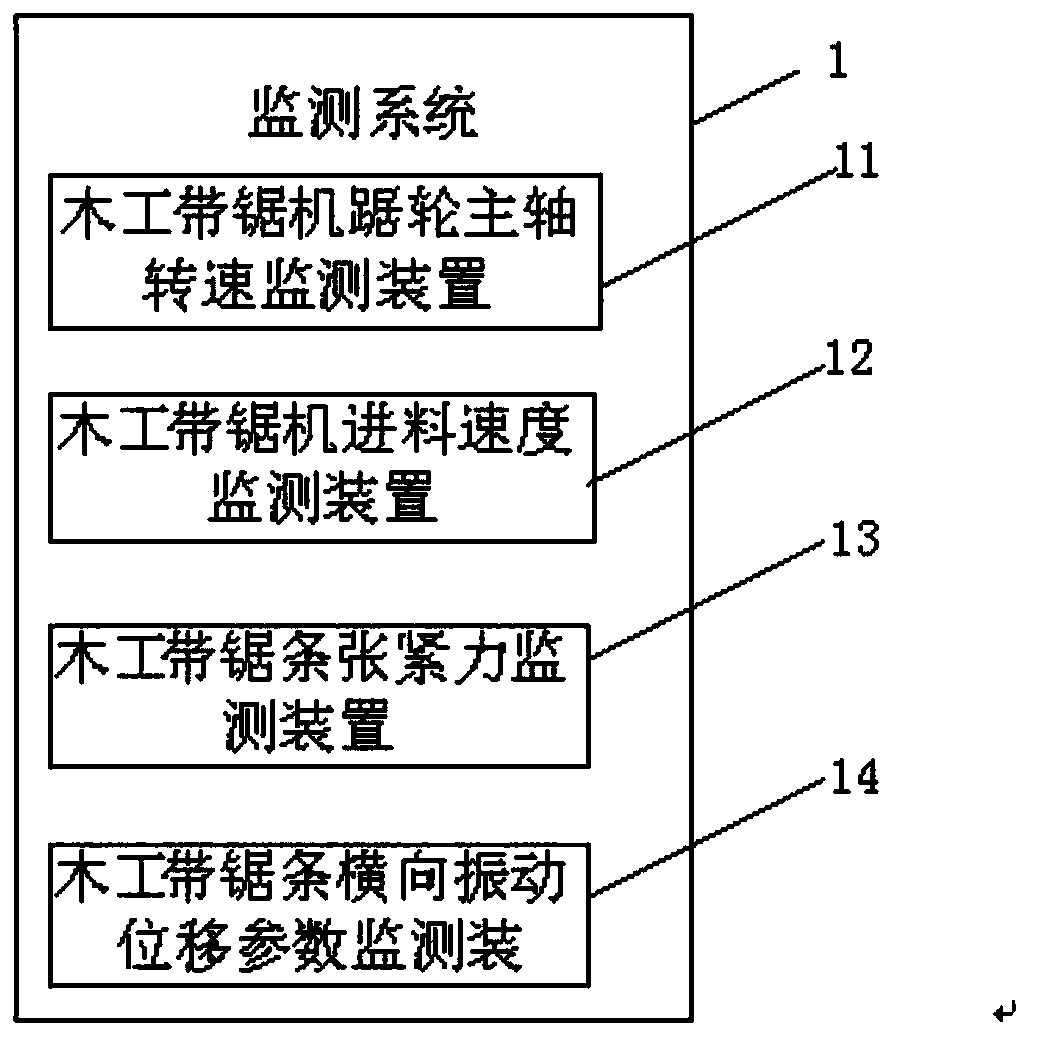

[0070] 1) Obtain the spindle speed, feed speed, tension force of the woodworking band saw blade, and lateral vibration displacement of the woodworking band saw blade of the woodworking band saw machine to be detected in real time;

[0071] The invention detects the probes of the non-contact eddy current sensor (or laser digital sensor), digital speed sensor and digital force senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com