Novel hydraulic dynamometer through flow structure

A hydraulic dynamometer and flow-through technology, which is applied in the measurement of electric power, parts and instruments of electrical measuring instruments, etc., can solve problems such as cavitation, and achieve the effects of improving accuracy, stable water flow characteristics and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

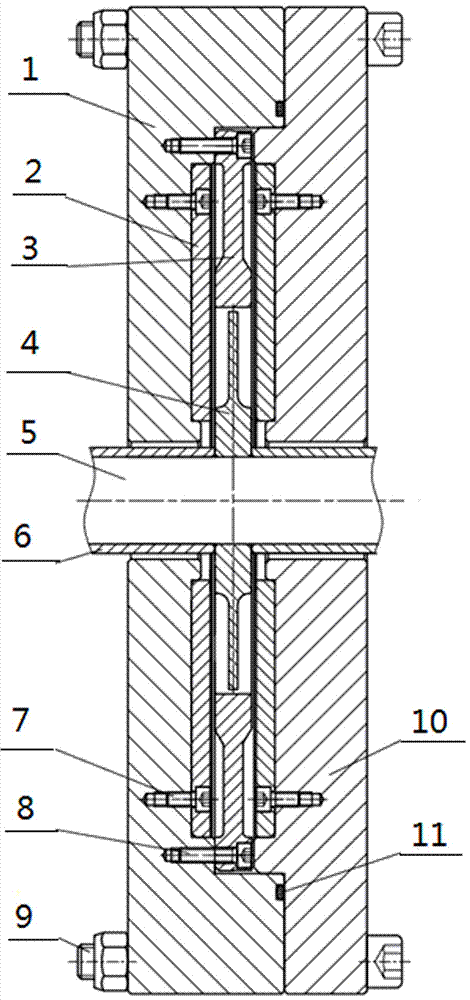

[0007] refer to figure 1 , a new type of hydraulic dynamometer flow structure, which includes a left half shell 1, a partition 2, a stator 3, a rotor 4, a main shaft 5, a shaft sleeve 6, a first connecting bolt 7, a second connecting bolt 8, The third connecting bolt 9, the right half shell 10 and the sealing ring 11, the partition plate 2 is respectively fixed on the left half shell 1 and the right half shell 10 by the first connecting bolt 7, the stator 3 is fixed by the second connecting bolt 8 On the left half shell 1, the left half shell 1 and the right half shell 10 are connected by the third connecting bolt 9 to form the stator water chamber of the flow part of the hydraulic dynamometer, the left half shell 1 and the right half shell The middle of the body 10 is sealed by a sealing ring 11, and the rotor 4 is fixed on the main shaft 5 through the sleeve 6 to form a dynamometer rotor assembly.

[0008] According to the absorbed power of the hydraulic dynamometer and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com