Device for measuring magnetization of soft ferrite pre-sintering material

A soft ferrite and pre-sintered material technology, applied in the direction of magnetic performance measurement, magnetization measurement, etc., can solve the problems of restricting the production of soft magnetic materials, research and development progress, long time period, high price, etc. Simple installation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

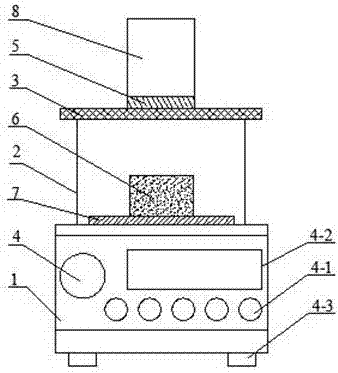

[0019] As shown in the accompanying drawings: a device for measuring the magnetization degree of soft ferrite calcined materials, including a weighing mechanism 1, a bracket 2 placed above the weighing mechanism 1 and a support member 3 at the upper end of the bracket 2, and the weighing mechanism 1 includes Electronic scale 4, electronic scale 4 is provided with function button 4-1, liquid crystal display 4-2 and the leg 4-3 of height adjustment, and permanent magnet 5 is placed on support member 3, and support 2 comprises four surrounding baffle plates, Four surrounding baffles are spliced into a "mouth" structure. The support 3 is a plate-shaped structure. The support 3 can seal the upper port of the support 2. The container 6 of the oxygen calcined material, the container 6 is a measuring cup, the weighing mechanism 1 is provided with a non-magnetic gasket 7, and the container 6 is placed on the gasket 7.

[0020] The support 2 is placed directly above the weighing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com