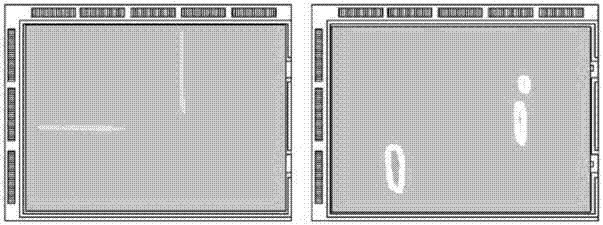

LCD screen Mura defect detection system and method

A defect detection and screen technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of not being able to simulate the observation effect of the human eye well, the detection results are not ideal, and there is no shape, etc., to achieve rich observation methods, comprehensive cloud grain defects, reducing the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

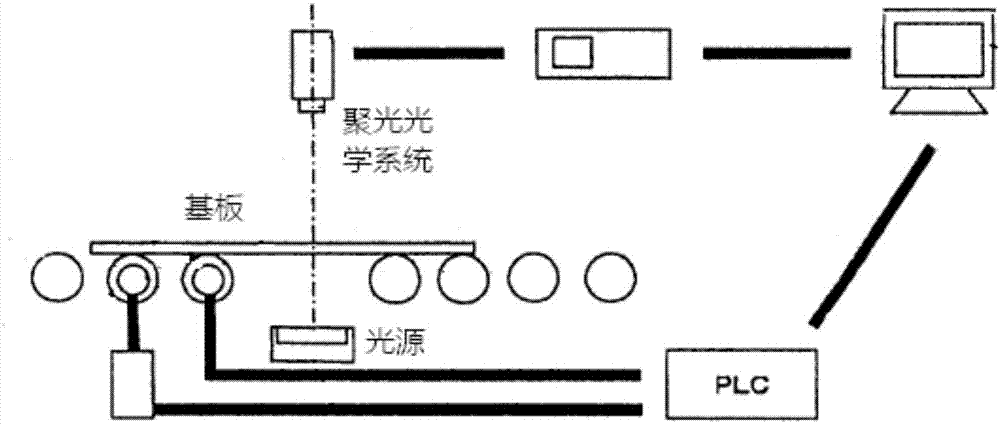

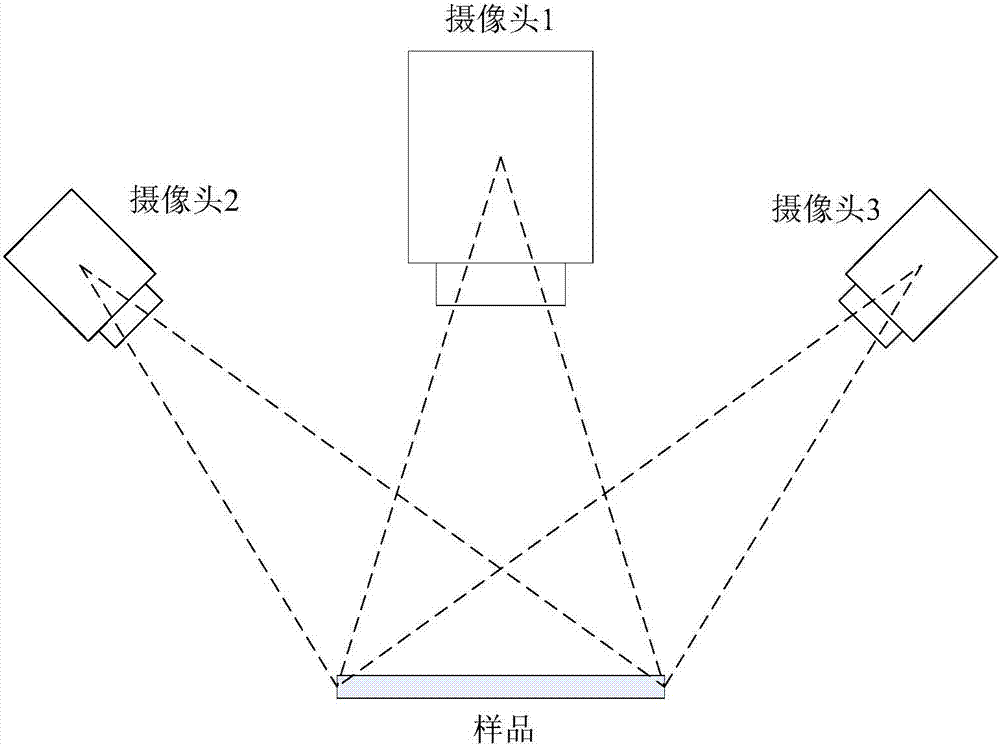

[0035] Please refer to Figure 4 , Figure 4 Shown is a schematic structural diagram of the moiré defect detection system in the first preferred embodiment of the present invention. The present invention proposes an LCD screen moiré defect detection system, comprising: a plane reflector 200, which is arranged on the side of the LCD screen 100 to be detected; and the LCD screen imaging 400 in the plane mirror 200 for shooting; the image processing module pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com