Flexible projected capacitive touch screen and manufacturing method thereof

A capacitive touch screen, projection technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problem that hard touch screen technology is difficult to apply flexible display and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0031] The invention discloses a flexible projected capacitive touch screen and a manufacturing method thereof. The flexible projected capacitive touch screen takes into account the characteristics of both hard substrate display and flexible display, and can be used for both hard substrate displays and flexible displays. monitor.

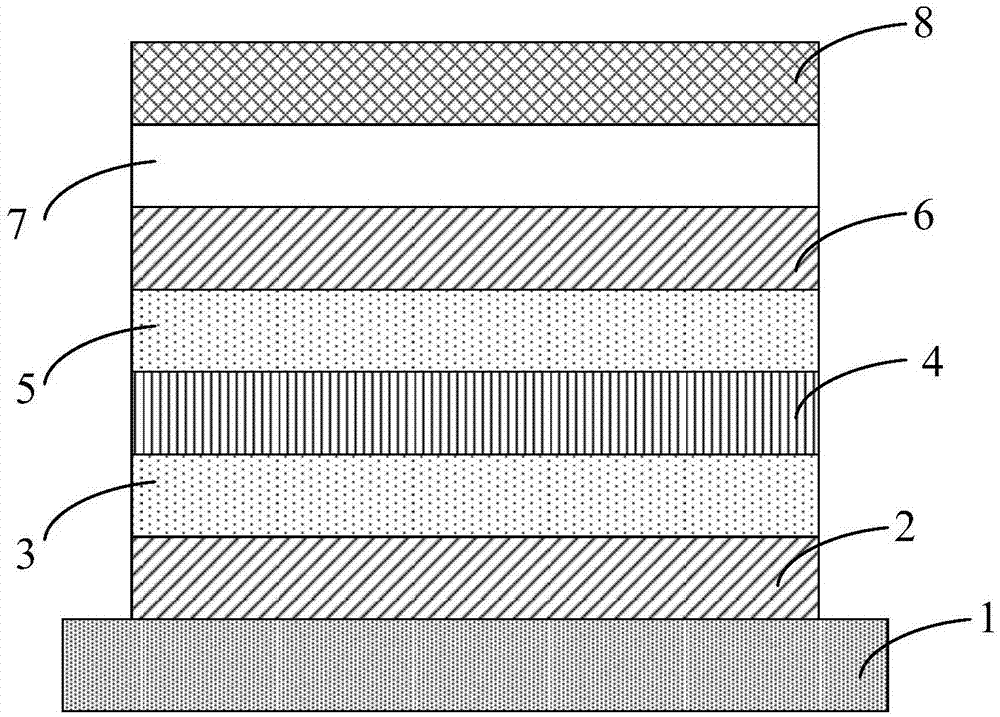

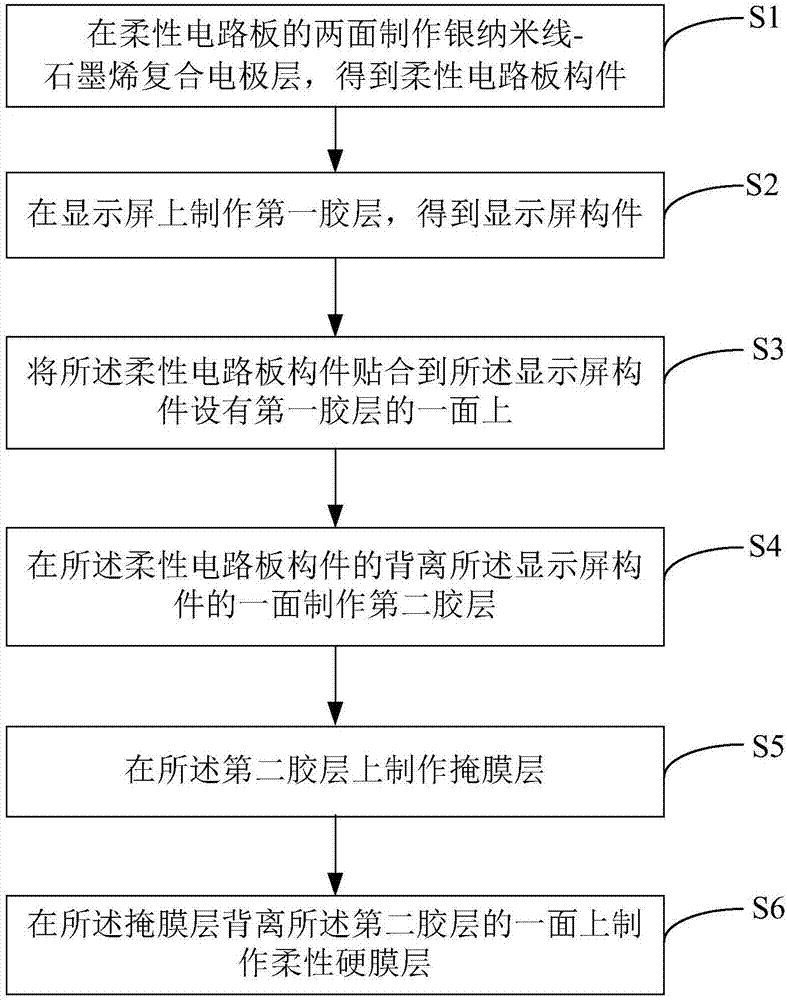

[0032] refer to figure 1 , is an embodiment of the flexible projected capacitive touch screen of the present invention. The flexible projected capacitive touch screen includes a display screen 1 and a flexible circuit board 4, the two sides of the flexible circuit board 4 are provided with silver nanowire-graphene composite electrode layers, and one side of the flexible circuit board 4 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com