Repetition frequency giant pulse gas-laser laser head

A gas laser and repetition rate technology, applied in the field of laser heads, can solve the problems of development limitation and stable operation difficulty of high-energy repetition rate pulsed lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

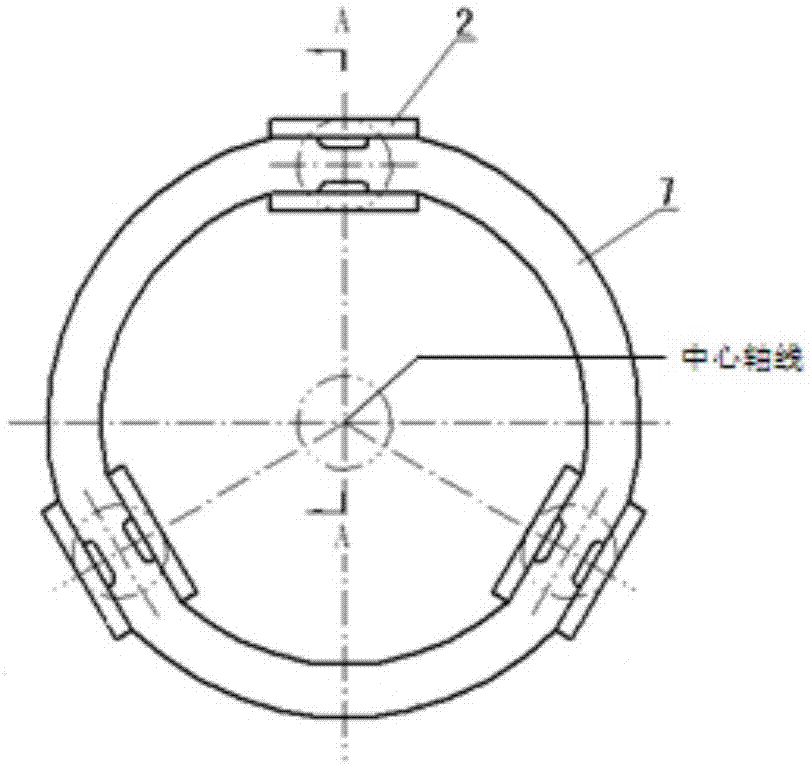

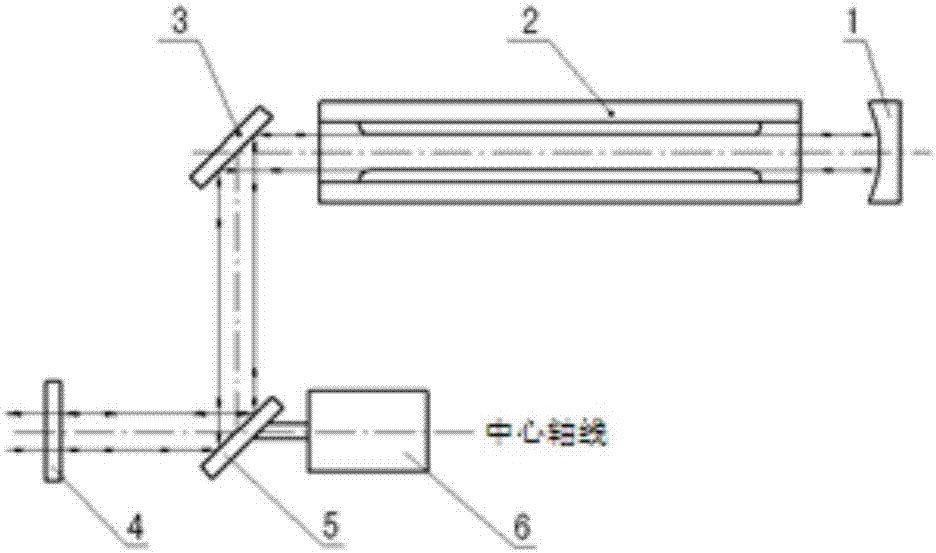

[0017] figure 1 It is a schematic cross-sectional layout diagram of a laser head with three groups of laser gain units with the same structure uniformly arranged on the structural cavity. The laser head in this embodiment includes three total reflection mirrors, three sets of laser gain units, three sub-plane total reflection mirrors, a plane partial reflection mirror 4, a plane total reflection mirror 5, a rotary drive device 6 and a structural cavity 7. The total reflection mirror is usually a concave mirror or a plane mirror. The concave mirror 1 is selected as the total reflection mirror in this embodiment.

[0018] The three groups of laser gain units have the same structure, and each group includes a pair of discharge electrodes. The three groups of laser gain units are evenly distributed in the structural cavity 7, and the three pairs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com