All-fiber structural laser system capable of generating high-energy wave-free split rectangular pulse

A rectangular pulse and laser system technology, applied to the structure/shape of the active medium, lasers, laser parts, etc., can solve the problem of difficult to achieve high-energy rectangular light pulse output, and achieve simple structure, easy adjustment, and good beam quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

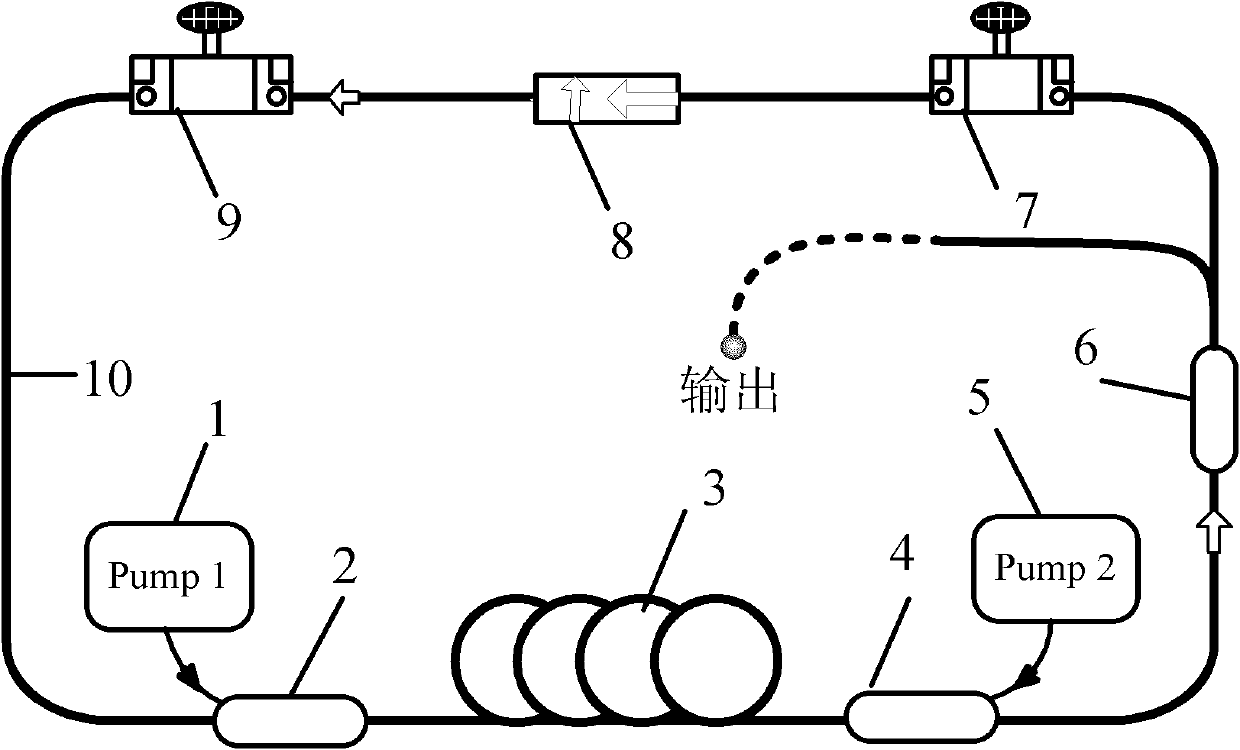

[0033] see figure 1 , the novel fiber laser system that the present invention is used to produce high-energy pulses without wave splitting includes: comprising a forward pumping light source 1, a first wavelength division multiplexer 2, and an erbium-doped gain fiber 3 connected sequentially through a single-mode optical fiber 10 , a second wavelength division multiplexer 4 , a backward pumping light source 5 , an output coupler 6 , a first polarization controller 7 , a polarization-dependent isolator 8 , and a second polarization controller 9 . A polarization-dependent isolator is connected to two polarization controllers through a single-mode fiber to form an equivalent saturable absorber. Both the forward pumping light source 1 and the backward pumping light source 5 are single-mode semiconductor lasers with a central wavelength of 980 nm, and the output power is adjustable from 0 to 500 mW. The wavelength division range of WDM 2 and 4 is 980nm / 1550nm. The type of erbium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com