A conveying mechanism for carbon dioxide polyurethane foaming machine

A technology of carbon dioxide and conveying mechanism, which is applied in the field of polyurethane foam material preparation, can solve problems such as the cylinder cannot work, the cylinder exhaust is not smooth, laborious and laborious, etc., and achieve the effect of changing the flow rate, simple structure and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

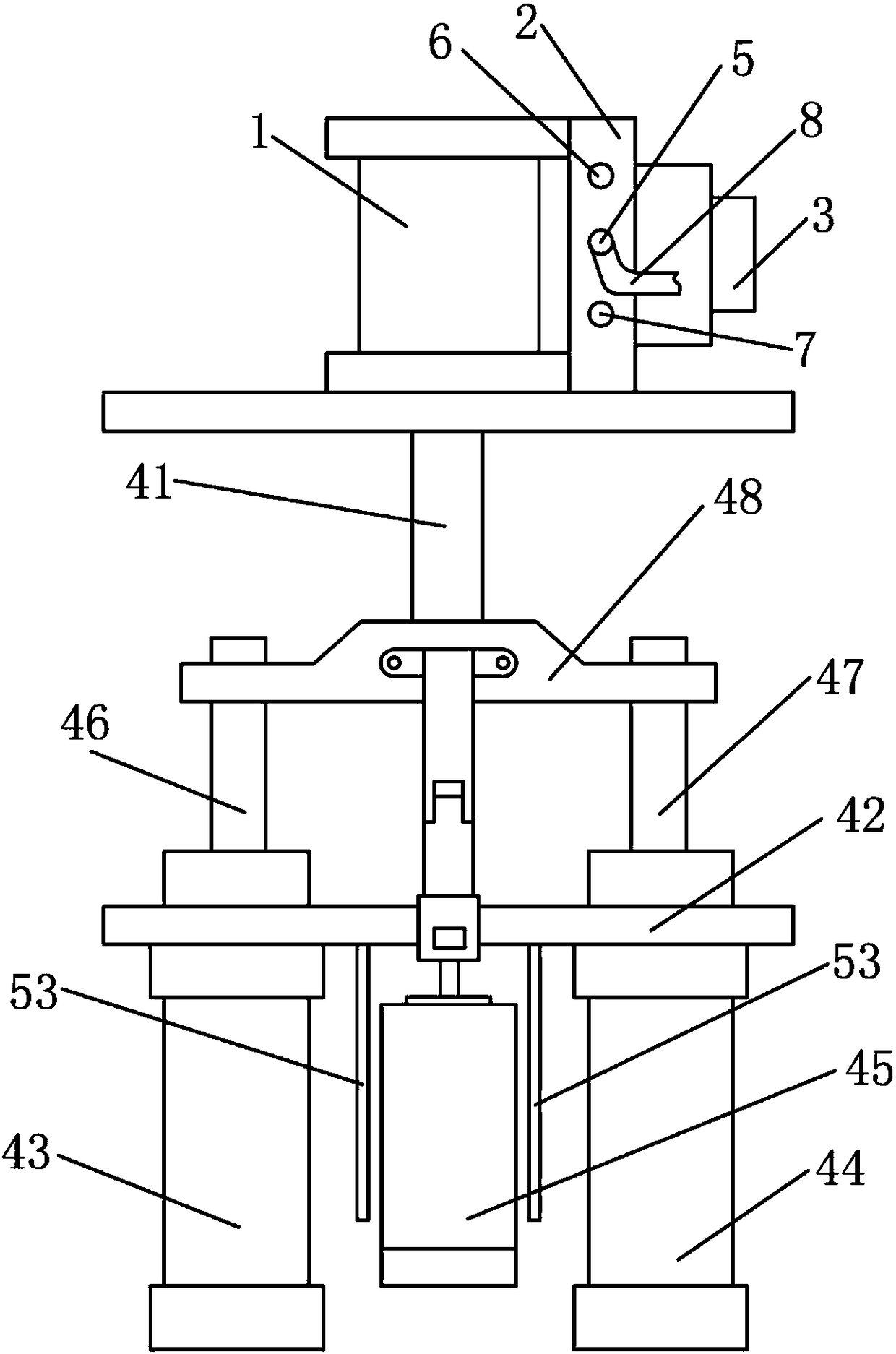

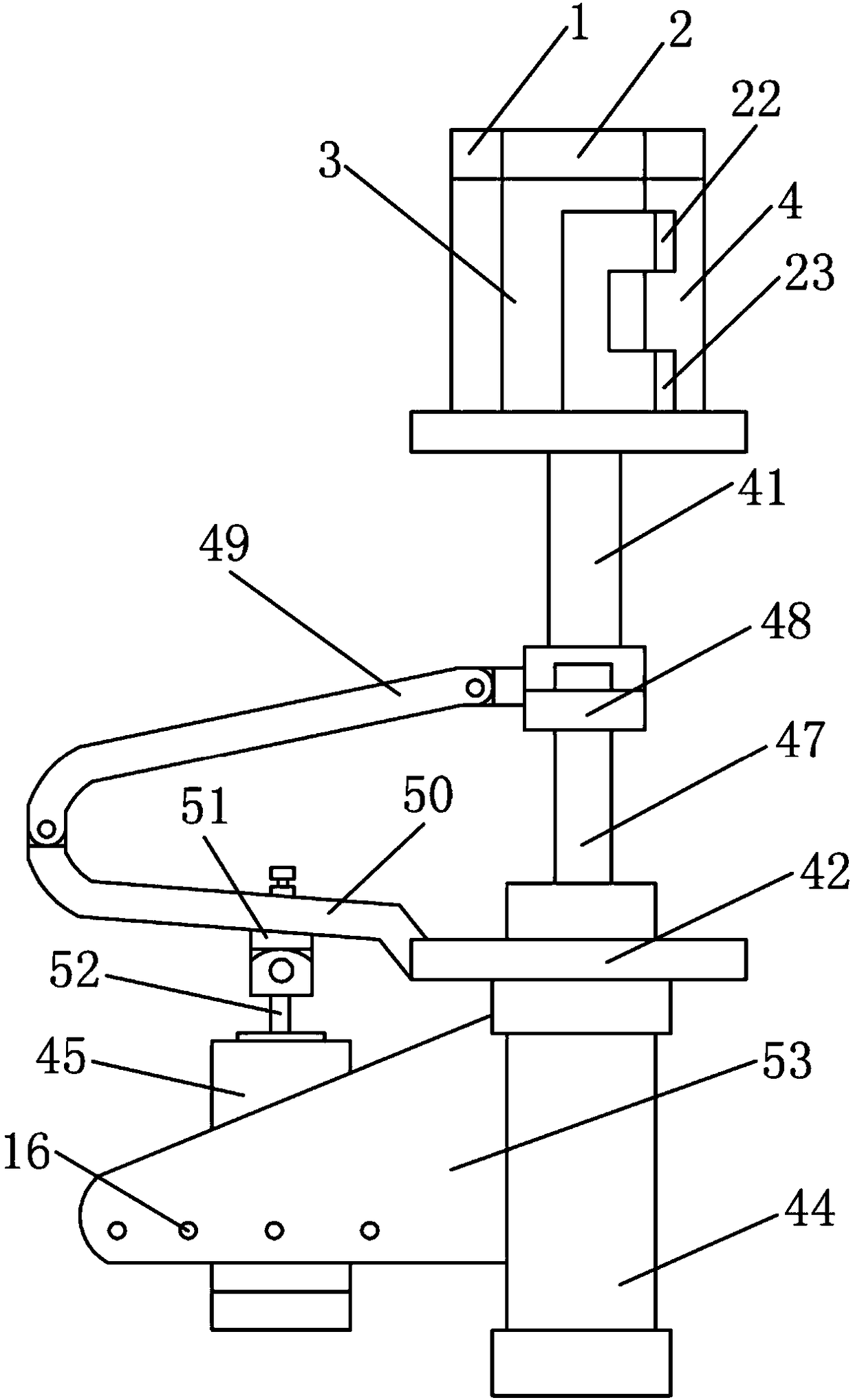

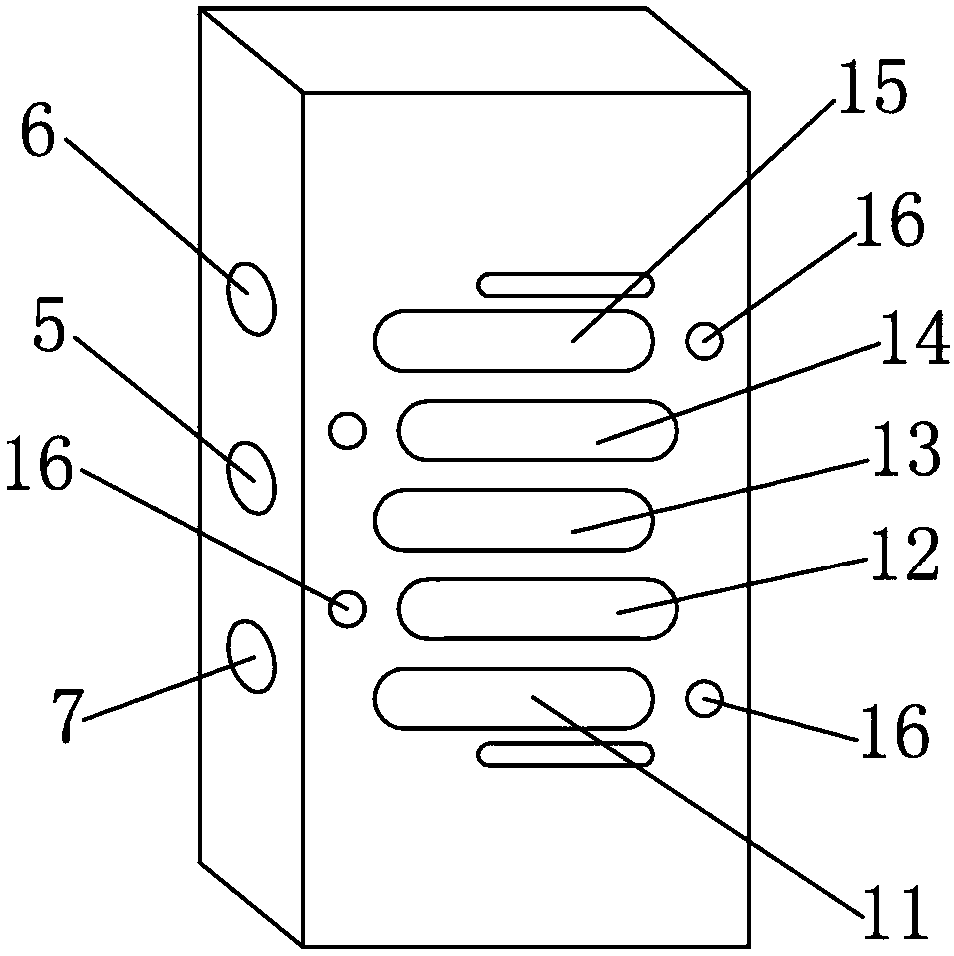

[0024] Embodiment: a kind of conveying mechanism that is used for carbon dioxide polyurethane foaming machine, as Figure 1-Figure 8As shown, it is used for quantitative delivery of isocyanate, combined polyether and carbon dioxide. It consists of a drive module and a linkage module. The drive module includes a drive cylinder, an aluminum block, a three-position five-way reversing valve and a heating device. The drive cylinder is set On the inner side of the aluminum block, the three-position five-way reversing valve is arranged on the outer side of the aluminum block, and the heating device is arranged on the rear side of the aluminum block; There is a piston, which divides the internal space of the cylinder into an upper cylinder and a lower cylinder, and the piston is provided with a drive rod; the outer surface of the aluminum block is provided with No. 2 groove, No. 3 groove, and No. 1 groove from bottom to top No. 1 groove, No. 4 groove and No. 5 groove, bolt holes are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com