Composite paint with good storage stability and preparation method of composite paint

A technology for storage stability and composite coatings, applied in alkali metal silicate coatings, coatings, etc., can solve the problems of poor storage stability of organic-inorganic composite coatings, and achieve the effect of increased storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

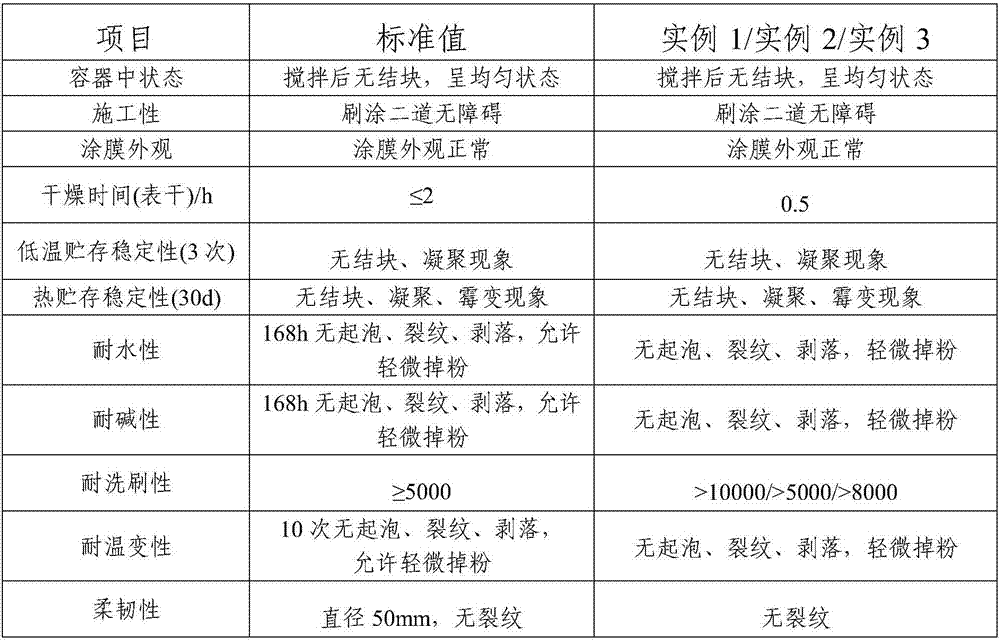

Embodiment 1

[0028] A composite coating with good storage stability, the composite coating is composed of the following components in parts by weight: 27 parts of water, 0.35 parts of hydroxyethyl cellulose, 0.7 parts of defoamer, 15 parts of titanium dioxide, 5 parts of talcum powder 25 parts, 25 parts of heavy calcium powder, 0.5 parts of stabilizer LOPON ST, 20 parts of potassium silicate solution (solid content 30%), 6.5 parts of emulsion and 0.8 parts of reinforcing agent.

[0029] Described talcum powder and heavy calcium powder are 1000 orders. The hydroxyethyl cellulose is TF-30000S, the emulsion is BASF's deodorant emulsion Acronal ECO 502ap, the enhancer is Aohan Shengchuan Chemical SC-010, and the potassium silicate solution is Aohan Shengchuan Chemical AH-K1.

[0030] The preparation method of the above-mentioned composite paint with good storage stability comprises the steps:

[0031] (1) First add 20 parts of water into the mixing tank, start stirring, adjust the stirring sp...

Embodiment 2

[0037] A composite coating with good storage stability, the composite coating is composed of the following components by weight: 32 parts of water, 0.39 parts of hydroxyethyl cellulose, 0.7 parts of defoaming agent, 10 parts of titanium dioxide, 5 parts of talcum powder 30 parts, 30 parts of heavy calcium powder, 0.5 parts of stabilizer LOPON ST, 15 parts of potassium silicate solution (solid content 30%), 6 parts of emulsion and 0.8 parts of reinforcing agent.

[0038] Described talcum powder and heavy calcium powder are 800 orders. The hydroxyethyl cellulose is TF-30000S, the emulsion is BASF's deodorant emulsion Acronal ECO 502ap, the enhancer is Aohan Shengchuan Chemical SC-010, and the potassium silicate solution is Aohan Shengchuan Chemical AH-K1.

[0039] The preparation method of the above-mentioned composite paint with good storage stability comprises the steps:

[0040] (1) First add 25 parts of water into the mixing tank, start stirring, adjust the stirring speed t...

Embodiment 3

[0046] A composite coating with good storage stability, the composite coating is composed of the following components in parts by weight: 28 parts of water, 0.37 parts of hydroxyethyl cellulose, 0.7 parts of defoamer, 12.5 parts of titanium dioxide, 5 parts of talcum powder 27.5 parts of heavy calcium powder, 0.5 parts of stabilizer LOPON ST, 17.5 parts of potassium silicate solution, 7.5 parts of emulsion and 0.8 parts of reinforcing agent.

[0047] Described talcum powder and heavy calcium powder are 1250 orders. The hydroxyethyl cellulose is Aqualon 250HBR, the emulsion is BASF's deodorant emulsion Acronal ECO 502ap, the enhancer is Aohan Shengchuan Chemical SC-010, and the potassium silicate solution (solid content 30%) is Aohan Shengchuan Chemical AH -K1.

[0048] The preparation method of the above-mentioned composite paint with good storage stability comprises the steps:

[0049] (1) First add 21 parts of water into the mixing tank, start stirring, adjust the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com