Large mining equipment

A kind of mining equipment, large-scale technology, applied in the field of large-scale mining equipment, can solve the problem of being difficult to meet the flexibility and convenience, and achieve the effect of light weight, large bearing capacity, no cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

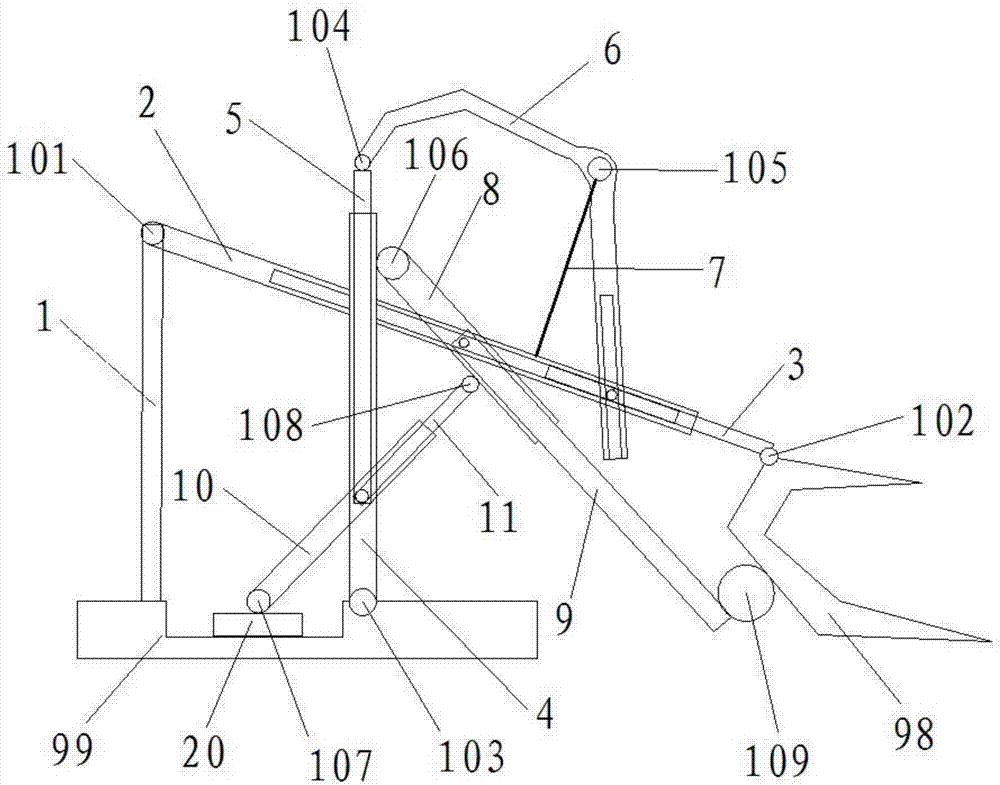

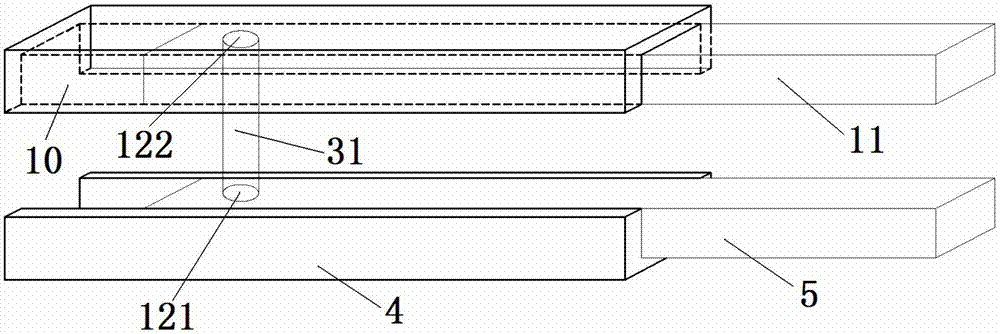

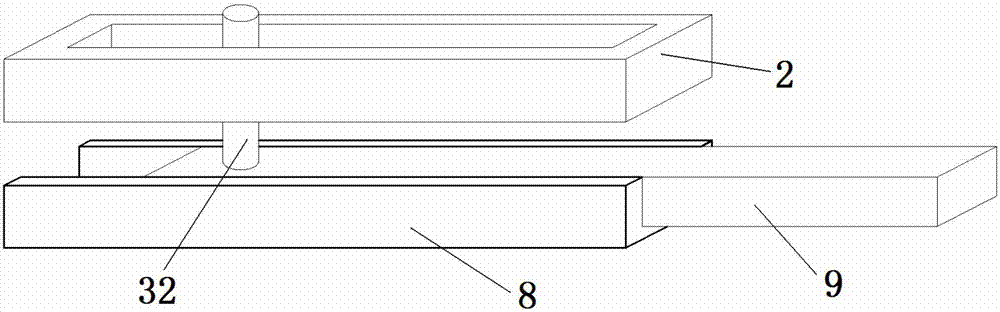

[0032] Large-scale mining equipment, including pole one 1, pole two 2, pole three 3, pole four 4, pole five 5, pole six 6, pole seven 7, pole eight 8, pole nine 9, pole ten 10, pole eleven 11, Slider 20, shaft rod 31, first cylindrical pin 32, second cylindrical pin 33, actuator 98 and frame 99,

[0033] One end of rod one 1 is fixed on the frame 99, the other end of rod one 1 is connected with one end of rod two 2 through rotating pair one 101, the other end of rod two 2 is connected with one end of rod three 3 through an axial movement pair to form a telescopic rod, and rod three 3. The other end is connected to the actuator 98 through the rotating pair 102;

[0034] One end of rod four 4 is connected on the frame 99 through rotating pair three 103, the other end of rod four 4 is connected with one end of rod five 5 through an axial movement pair to form a telescopic rod, and the other end of rod five 5 is connected to rod six 6 through rotating pair four 104 One end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com