Self-aligning liquid crystal display panel and manufacturing method thereof

A technology for a liquid crystal display panel and a manufacturing method, which are applied in optics, instruments, nonlinear optics, etc., can solve problems such as difference in alignment force, display defects of bright and dark lines, etc., and achieve low production costs, saving alignment film materials, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

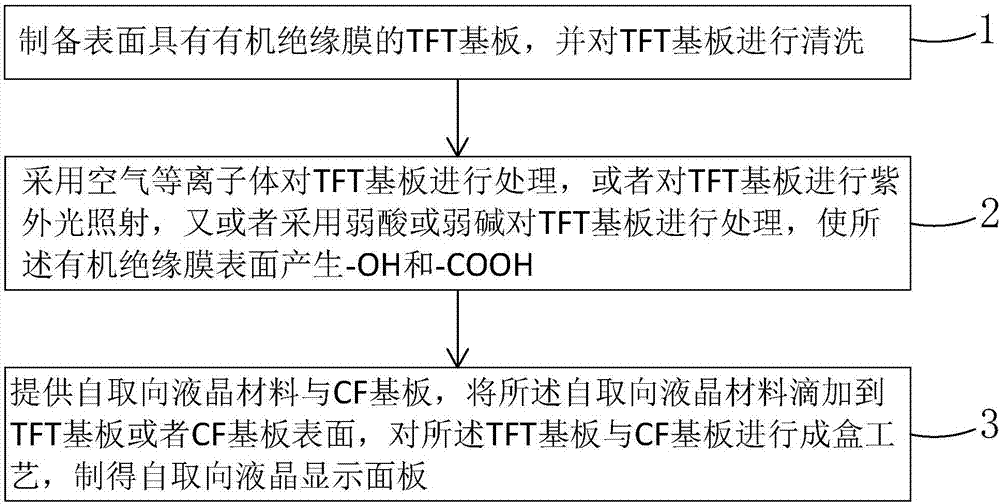

[0035] see figure 1 , the present invention at first provides a kind of manufacture method of self-orientation liquid crystal display panel, comprises the following steps:

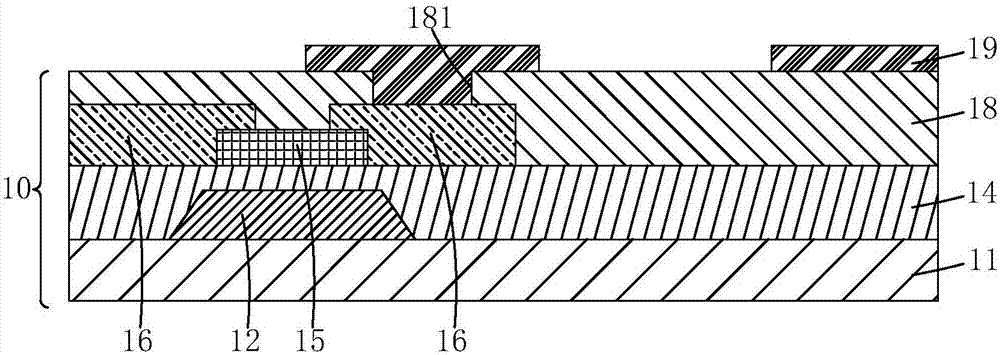

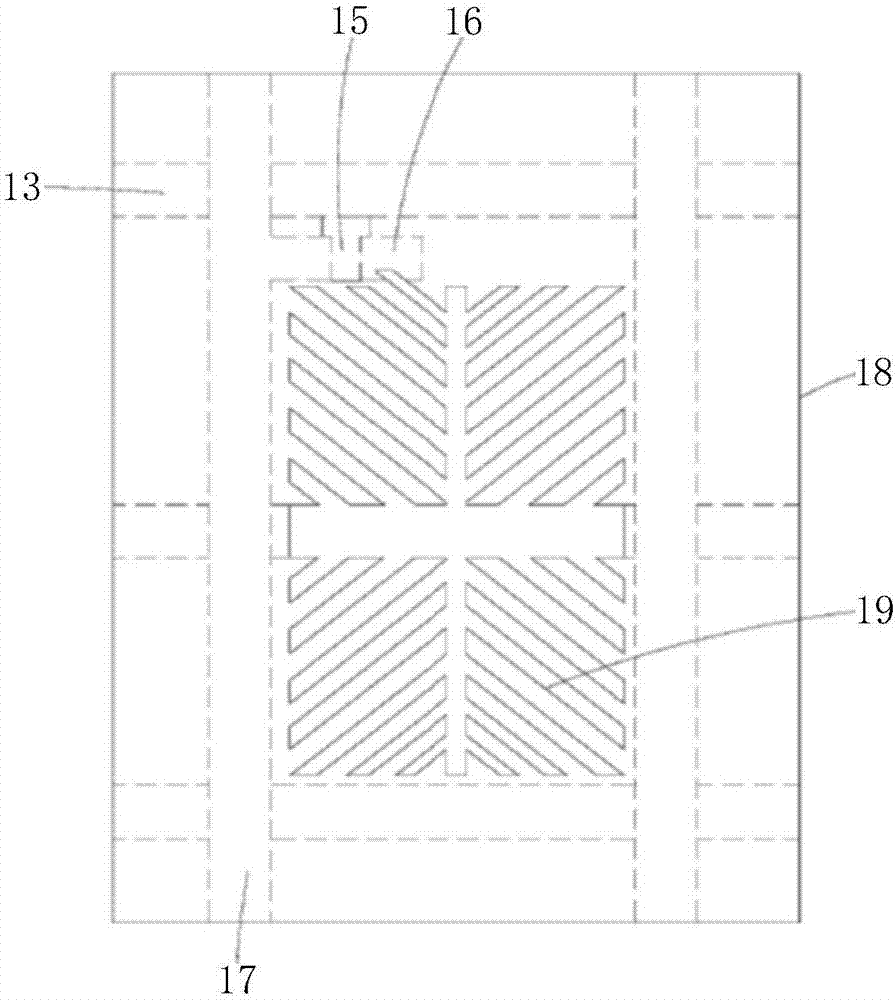

[0036] Step 1, such as figure 2 and image 3 As shown, a TFT substrate 10 with an organic insulating film on the surface is prepared, and the TFT substrate 10 is cleaned.

[0037] Specifically, such as figure 2 and image 3 As shown, the TFT substrate 10 includes a glass substrate 11, a gate 12 and a scanning line 13 disposed on the glass substrate 11, and a gate insulation covering the gate 12 and the scanning line 13 disposed on the glass substrate 11. layer 14, the active layer 15 disposed on the gate insulating layer 14, the source / drain 16 disposed on the activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com