Comfortable, efficient and environmentally-friendly cutting machine

An environmentally friendly, cutting machine technology, applied in the field of steel structure manufacturing, can solve problems such as labor and time consumption, arm discomfort of staff, and large occupied space, so as to reduce the occupied space and prevent weeds from flying around. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

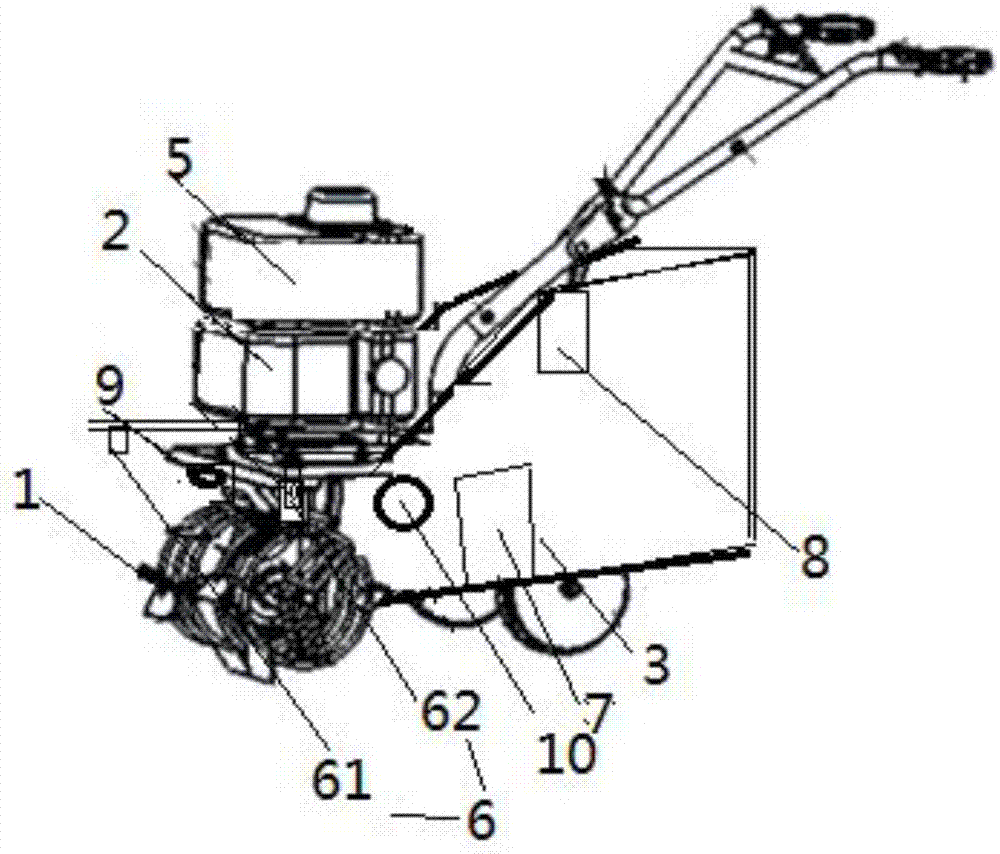

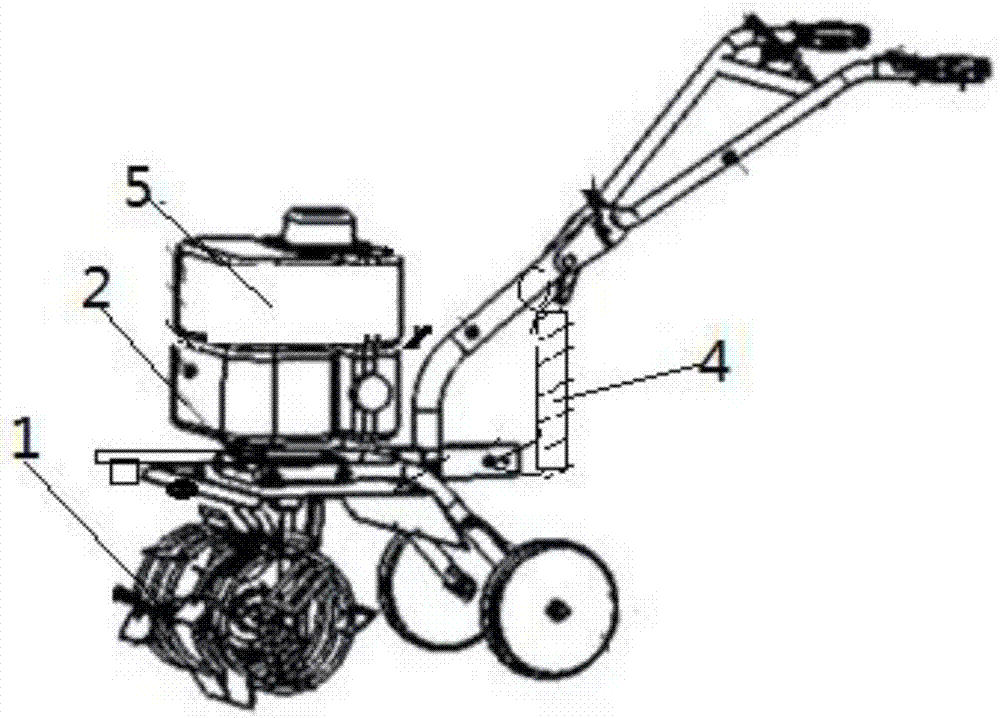

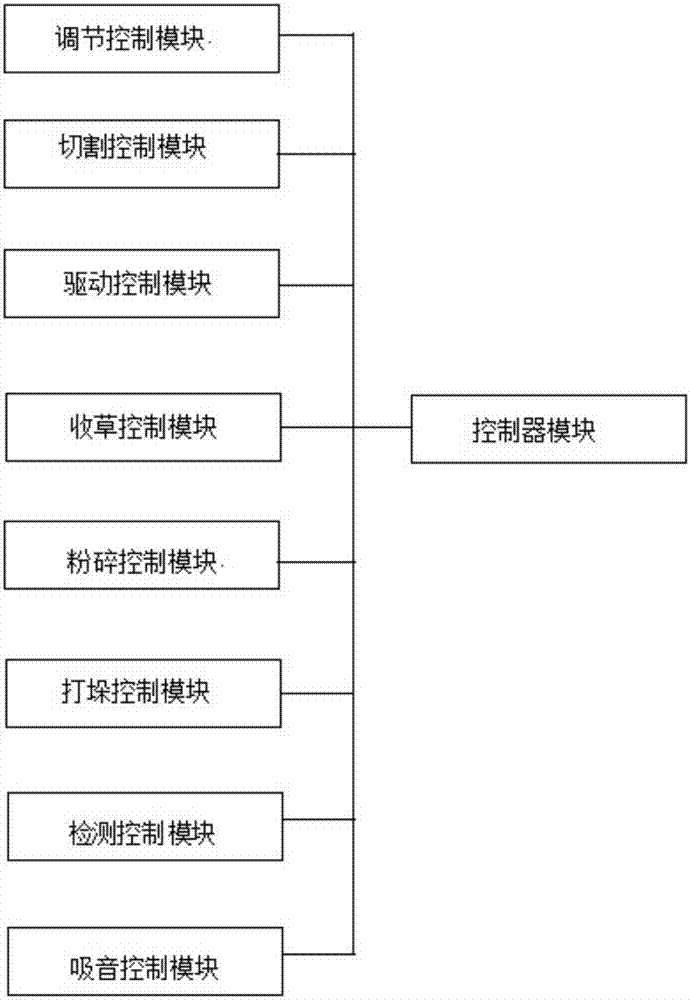

[0037]A comfortable, high-efficiency and environment-friendly cutting machine as shown in the figure includes: a mower body, on which a cutting mechanism 1, a driving mechanism 2, a grass harvesting mechanism 3, a shock-absorbing mechanism 4, and a sound-absorbing mechanism are arranged. Device 10 and control device 5, wherein, described cutting mechanism 1 is provided with the adjusting device 6 that is used to adjust the height of mowing grass, is provided with pulverizing device 7 in described grass collecting mechanism 3, the input and output end of described driving mechanism 2 They are respectively connected with the cutting mechanism 1, the grass harvesting mechanism 3 is arranged at the rear of the cutting mechanism 1, the shock absorbing mechanism 4 is arranged on the armrest of the lawnmower, and the sound-absorbing device 10 is arranged on one side of the lawnmower body , the cutting mechanism 1 , the driving mechanism 2 , the grass collecting mechanism 3 , the dampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com