Embedded ultrahard cutter and manufacturing method

An embedded, super-hard technology, applied to lathe tools, cutting blades, manufacturing tools, etc., can solve the problems of reduced production efficiency, general chip breaking effect, disrupted production cycle, etc., and achieve the effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

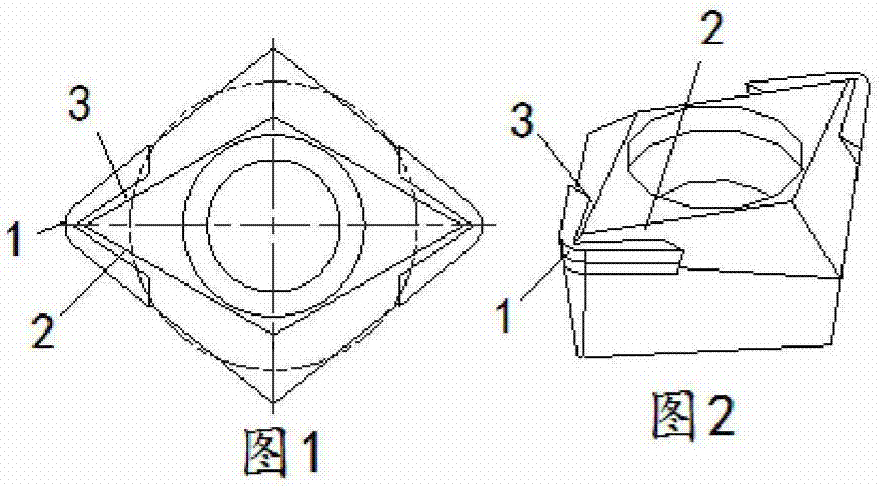

[0067] Embodiment 1: as figure 1 , figure 2 As shown, an embedded superhard cutting tool, the cutter head is welded on the corner of the blade, the cutter head has a cutting edge 1, and there are first chip breaker 2 and second chip breaker 2 on the surface of the cutting edge, that is, the two sides of the cutting edge 1, respectively. The chip breaker 3, the blade has a middle hole or no middle hole, and the first chip breaker 2 and the second chip breaker 3 respectively coincide with the slope on the top of the blade.

Embodiment 2

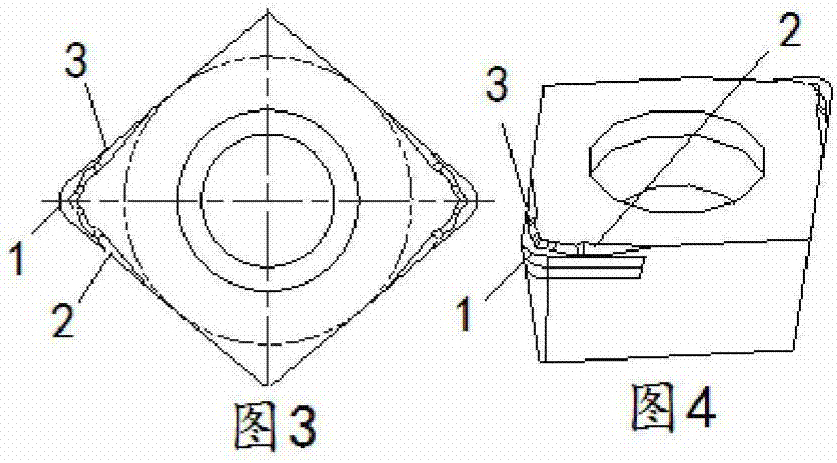

[0068] Embodiment 2: as image 3 , Figure 4 As shown, an embedded superhard cutting tool, the cutter head is welded on the corner of the blade, the cutter head has a cutting edge 1, and there are first chip breaker 2 and second chip breaker 2 on the surface of the cutting edge, that is, the two sides of the cutting edge 1, respectively. The chip breaker 3, the insert has a center hole or no center hole, and the first chip breaker 2 and the second chip breaker 3 are the changing sides.

Embodiment 3

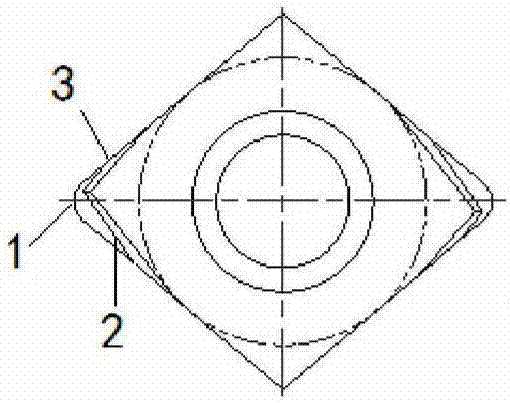

[0069] Embodiment 3: as Figure 5 , Image 6As shown, a kind of embedded superhard cutting tool, the cutting head is welded on the corner of the blade, the cutting head has a cutting edge 1, on the surface of the cutting head, that is, on both sides of the cutting edge 1, there are respectively a first chip breaker 2 and a second Chip breaker 3, the insert has a center hole or no center hole, the first chip breaker 2 and the second chip breaker 3 are located asymmetrically behind the tool tip 1, the first chip breaker 2 and the second chip breaker 3 The sides are flat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com