Grinding machine

A grinding machine and grinding mechanism technology, applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., to improve work efficiency and practicability, and prevent damage to abrasive tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

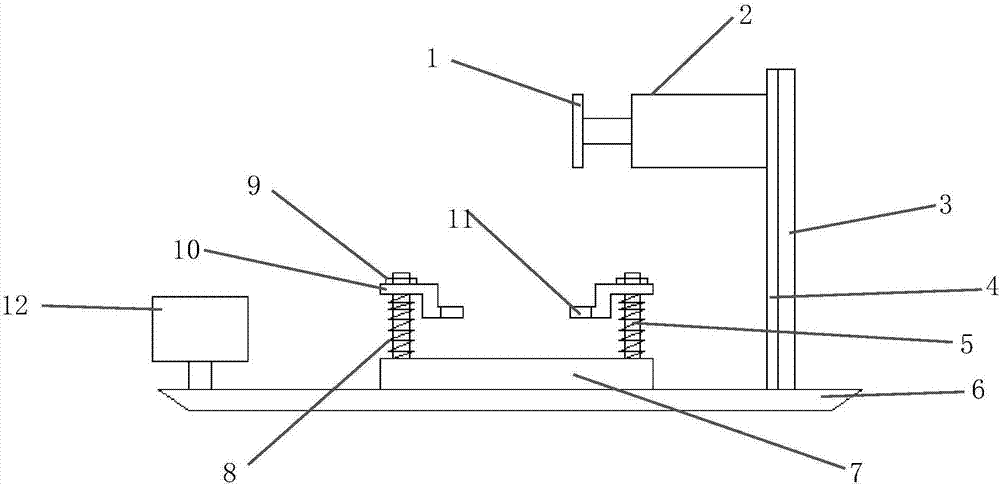

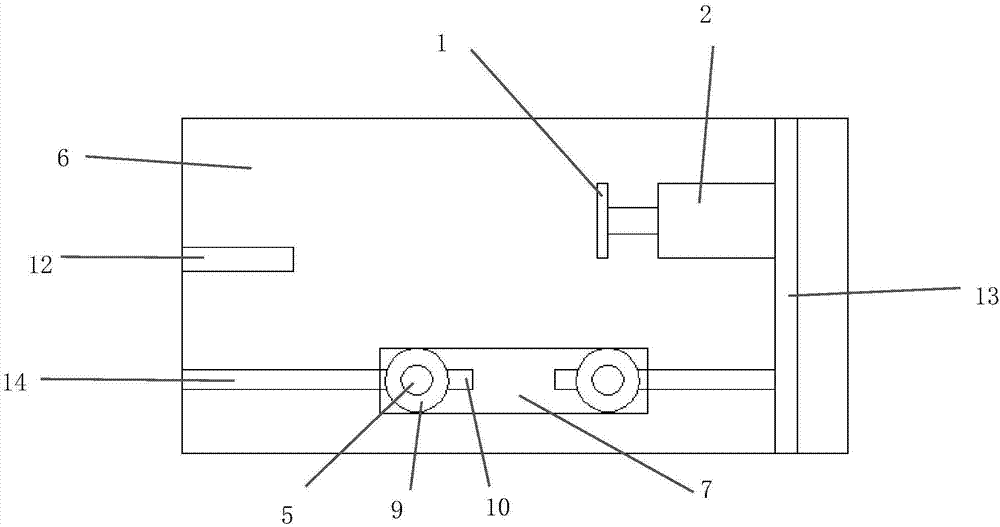

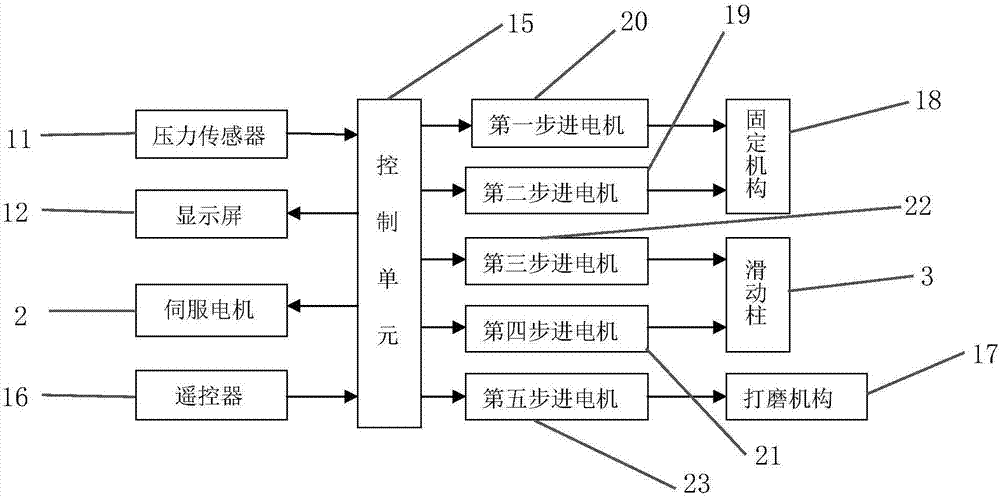

[0019] A kind of grinder of present embodiment, as figure 1 , figure 2 , image 3 Shown, comprise base 6, grinding mechanism 17, fixing mechanism 18, control unit 15, sliding column 3, remote controller 16, the display screen 12 that is arranged on the base, the first stepper motor 20 that is connected with fixing mechanism, and fixing The second stepping motor 19 that mechanism is connected, the 3rd stepping motor 22 that is connected with sliding column, the 4th stepping motor 21 that is connected with sliding column, the 5th stepping motor 23 that is connected with grinding mechanism, is arranged on the base The horizontal slide rail 14, the longitudinal slide rail 13 arranged on the base and the grinding slide rail 4 arranged on the sliding column; the sliding column is arranged on the longitudinal slide rail; the grinding mechanism is arranged on the grinding slide rail, and the grinding mechanism includes a grinding wheel 1 and the servo motor 2, the grinding wheel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com