Planar precession type ship gyro stabilizer

A plane and gyro technology, which is applied in the direction of directly using the gyroscope to reduce the movement of the ship, and can solve the problems that the ship anti-rolling gyro cannot be developed in a large-scale direction, large load force and impact, and bearings cannot bear it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

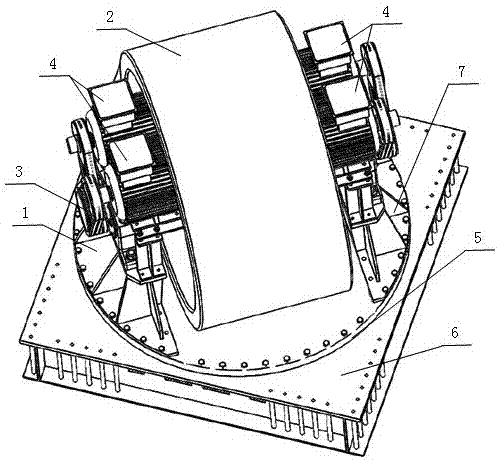

[0008] figure 1 Among them, the planar precession ship anti-rolling gyro includes a rotor 2, a frame 1, a base 6, and the like. The rotor 2 is installed on the frame 1 through the rotor shaft 3, and the rotor shaft 3 is set horizontally, so the force on the bearing supporting the rotor shaft is only radial force and no axial force; and it can be seen from the figure that the space at the bearing There is a large margin, which is convenient for the selection and installation of heavy-duty bearings; the static load of the bracket supporting the bearing on frame 1 is only compressive stress (the tangential stress of dynamic load is also small), instead of the original cantilever beam force structure, Therefore, the bearing capacity of the bracket is significantly improved. The frame 1 forms a rotating pair through the plane slewing bearing 5 and the base 6. It can be seen from the figure that the diameter of the plane slewing bearing is large, so the ability to carry the bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com