Coal conveyer emergency braking device and method

A technology for emergency braking and coal conveyors, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects. It can solve problems such as uneven force on the belt, deviation, and unfavorable emergency treatment, so as to avoid damage to equipment. , Fast and accurate positioning, easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

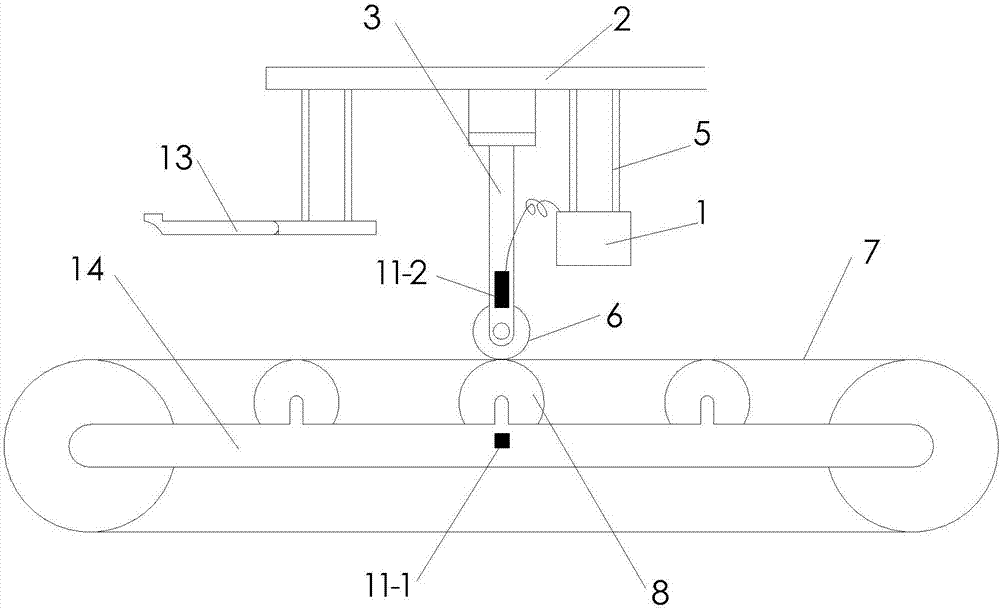

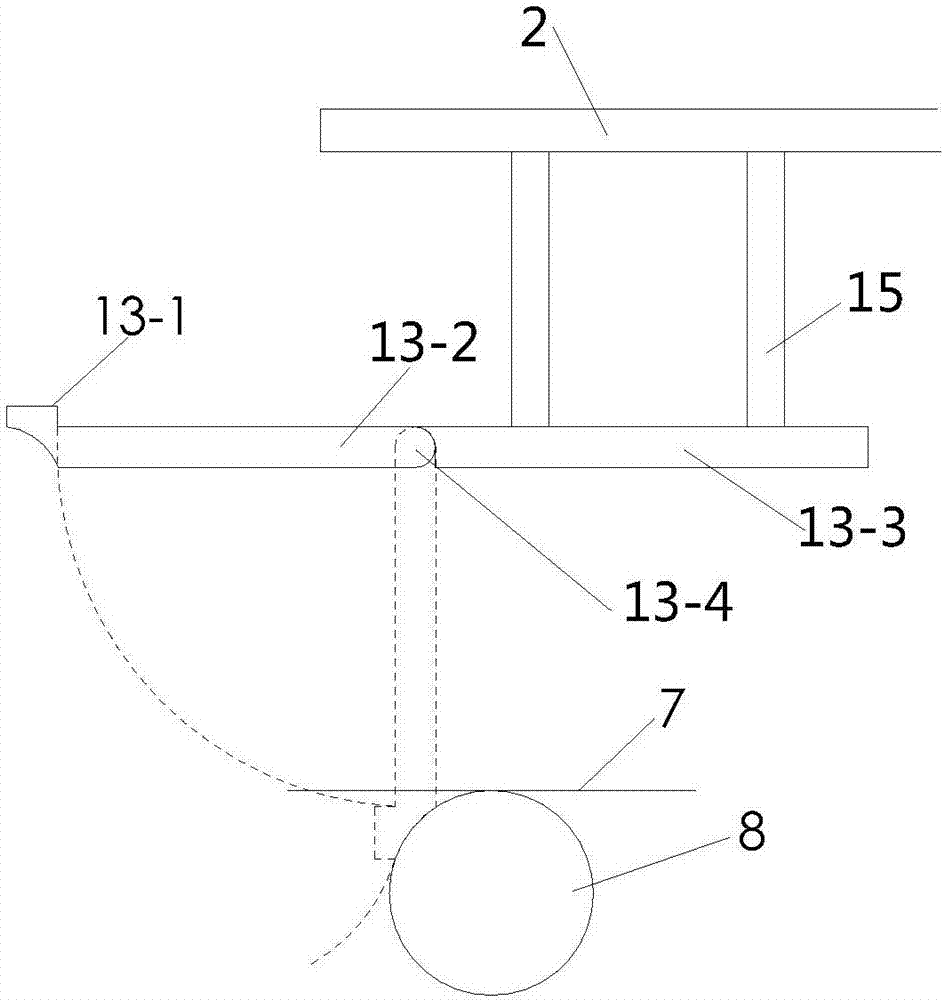

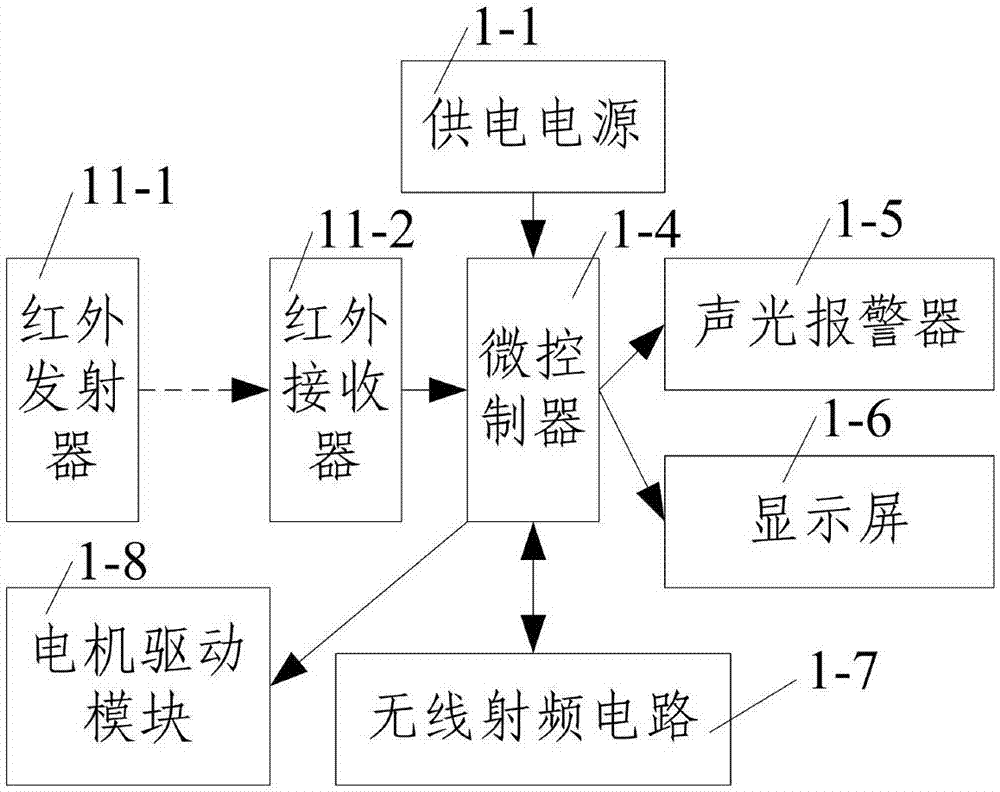

[0039] Such as Figure 1 to Figure 3 As shown, the emergency braking device of the coal transporter according to the present invention includes a remote console of the coal transporter and a plurality of emergency braking devices that communicate wirelessly with the remote console of the coal transporter, and the emergency braking device It includes a bracket 2 arranged above the coal conveyor, a brake mechanism mounted on the bracket 2 and cooperating with the auxiliary roller 8, an infrared detector for detecting the breakage of the belt 7 of the coal conveyor, and a brake mechanism for controlling the operation of the brake mechanism. The control box 1, the brake mechanism includes a vertical bar 3 fixed on the bracket 2 at one end, an electric pulley 6 that is rotatably mounted on the other end of the vertical bar 3 and in contact with the coal conveyor belt 7, and is used to press the coal conveyor The mechanical arm 13 of the belt 7, the infrared detector is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com