A kind of preparation method of tc4 titanium alloy sheet material for 3c product

A technology for titanium alloy plates and products, which is applied in the field of preparation of TC4 titanium alloy plates for 3C products, can solve the problems of large amount of machining of plates, low material yield, uneven color, etc. The effect of improving yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

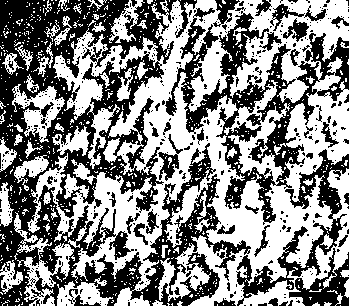

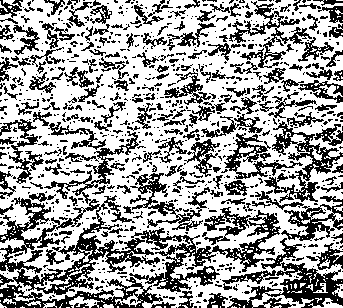

Image

Examples

preparation example Construction

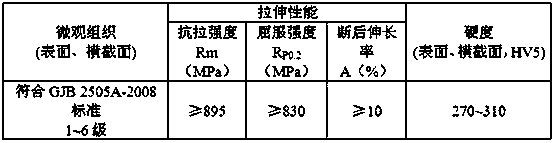

[0029] A preparation method of TC4 titanium alloy sheet material for 3C products, comprising the following steps: Step 1, using titanium sponge, aluminum vanadium master alloy, aluminum particles and titanium dioxide powder with a purity greater than 99.5% for batching and pressing electrodes, and then using vacuum plasma The welding box is used for electrode group welding, and the vacuum consumable electric arc furnace is used for smelting. The number of smelting is not less than 2 times. After the last smelting, the ingot riser is cut off and the lathe is peeled to obtain the ingot; among them, the sponge The purity of titanium is grade 0 or 0 A Grade sponge titanium, and remove the powdered sponge titanium rich in N, O and Fe impurity elements with a particle size below 3mm. The particle size of the sponge titanium is 3-12.7mm; the components and mass fractions of the prepared ingot are: Al 5.7~6.3%, V 3.7~4.3%, Fe 0.10~0.25%, C≤0.05%, N ≤0.02%, O 0.05~0.10%, H ≤0.002%, and...

Embodiment 1

[0041] A method for preparing a TC4 titanium alloy sheet for 3C products, the target size of the TC4 titanium alloy sheet is length×width×thickness=155×80×7mm; comprising the following steps:

[0042] The first step, ingot smelting: select 0-grade sponge titanium, aluminum vanadium master alloy, aluminum beans and 99.8% pure titanium dioxide powder in the particle size range of 3~12.7mm for batching, pressing and welding electrodes, and secondary smelting in vacuum consumable electric arc furnace , then remove the riser and peel off the skin, and take samples at the ingot head, middle and tail, and test the composition, and the composition is as shown in table 2;

[0043] The second step, slab preparation: use the metallographic method to measure the β phase transition temperature T of the above-mentioned TC4 ingot β =960°C. The ingot is heated to 1100°C for one-fire pier drawing forging, the total deformation of the second fire is 180%, and the billet is ground for second-fi...

Embodiment 2

[0056] A method for preparing a TC4 titanium alloy sheet for 3C products, the target size of the TC4 titanium alloy sheet is length×width×thickness=225×100×20mm; comprising the following steps:

[0057] The first step, ingot smelting: choose 3~12.7mm particle size range 0 A Grade sponge titanium, aluminum vanadium master alloy, aluminum beans and 99.8% pure titanium dioxide powder are used for batching, pressing and welding electrodes, and secondary smelting in vacuum consumable electric arc furnace. , Tail sampling, test composition, the composition needs to meet Al 5.7~6.3%, V 3.7~4.3%, Fe 0.10~0.25%, C≤0.05%, N ≤0.02%, O 0.05~0.10%, H ≤0.002%, other The amount is Ti;

[0058] The second step, slab preparation: use the metallographic method to measure the β phase transition temperature T of the above-mentioned TC4 ingot β =965°C. The ingot is heated to 1160°C for one-fire pier-drawing forging, and the total deformation of the fire is 250%. The total deformation of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com