Scroll compressor and compressor system

A scroll compressor and compressor system technology, applied in the field of scroll compressors, can solve problems such as insufficient cooling, affecting volumetric efficiency, and suction superheat, and achieve the goal of improving cooling, increasing volumetric efficiency, and reducing suction superheat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description of the preferred embodiments is exemplary only, and in no way limits the invention, its application or usage.

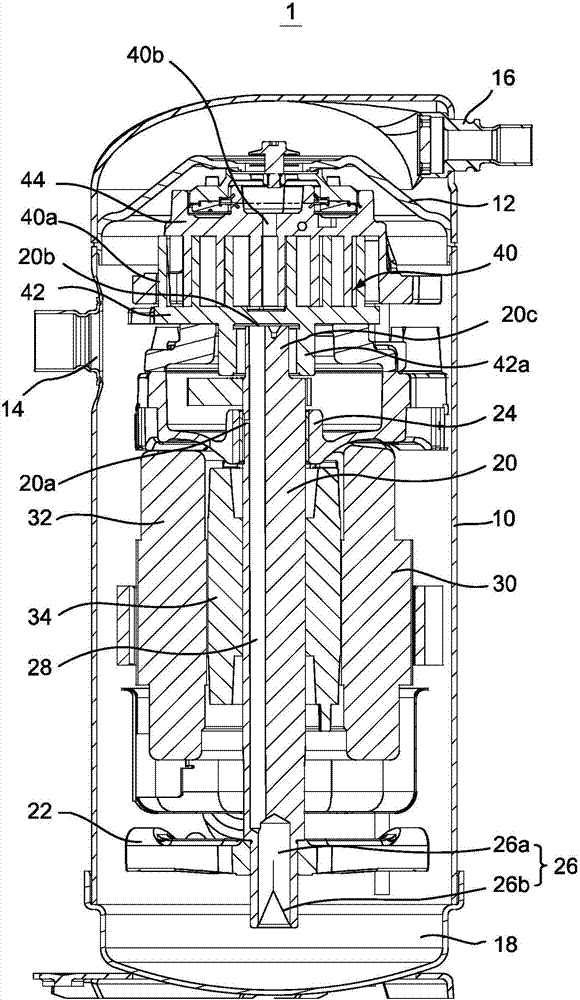

[0046] figure 1 An example of a known low pressure side scroll compressor is shown in cross section through the intake and exhaust ports. like figure 1 As shown, the low-pressure side scroll compressor 1 is a vertical compressor, which mainly includes: a casing 10 , a rotating shaft 20 , a motor 30 and a scroll mechanism 40 , which are described in detail below.

[0047] A partition 12 is provided in the housing 10 to partition the inner space of the housing 10 into a low pressure region (space below the partition 12 ) and a high pressure region (space above the partition 12 ). For the low pressure side compressor 1, both the motor 30 and the scroll mechanism 40 are accommodated in the low pressure region. The housing is provided with an air inlet 14 and an air outlet 16 for sucking in the refrigerant and discharging the compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com