Retention pin having foot for holding spring in disc brake pack reaction plate during assembly and for operating stator disc

A technology of reaction plate and holding pin, which is applied in the direction of brakes, brake components, hydraulic brakes, etc., and can solve the problems of stator disc wear and spring falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

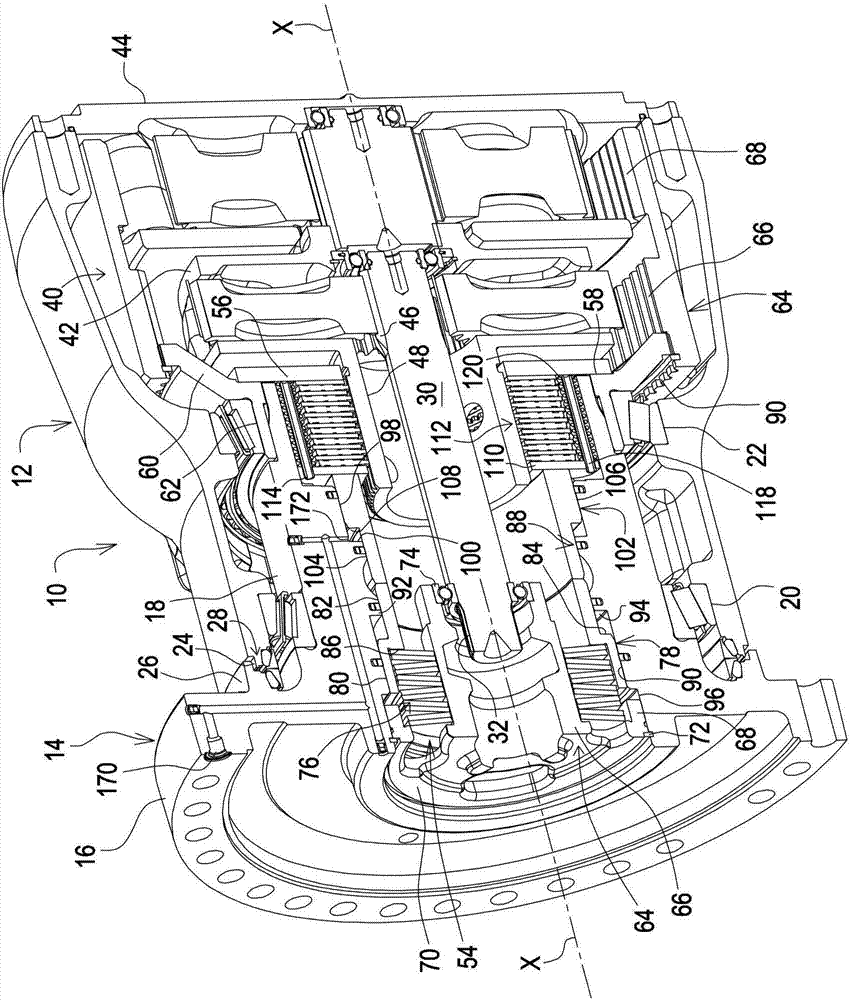

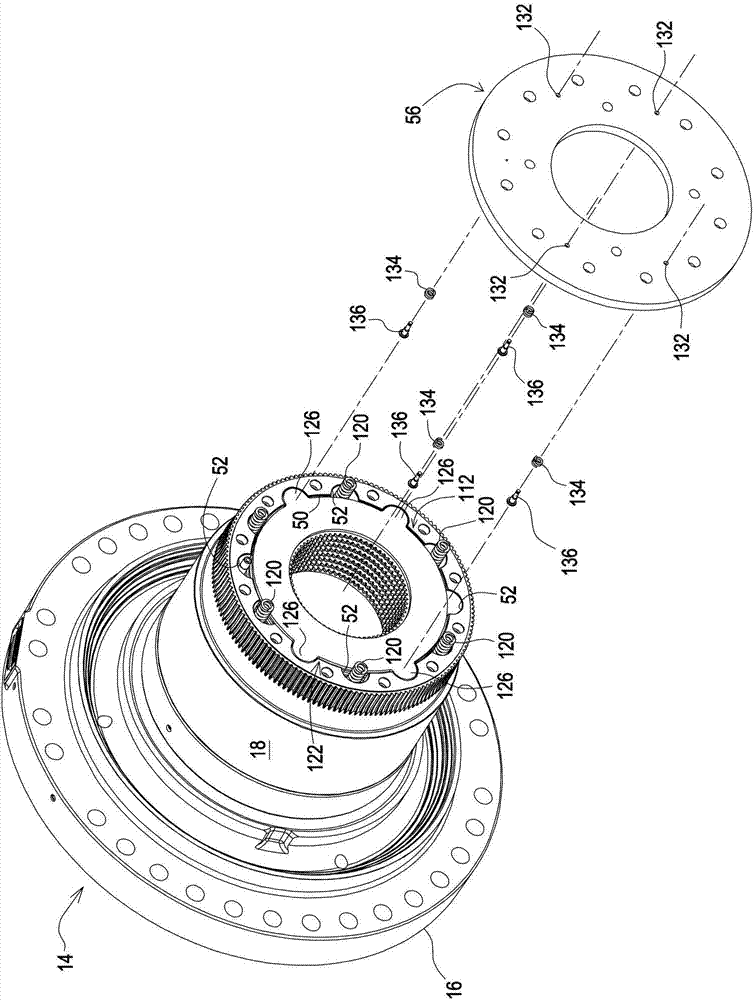

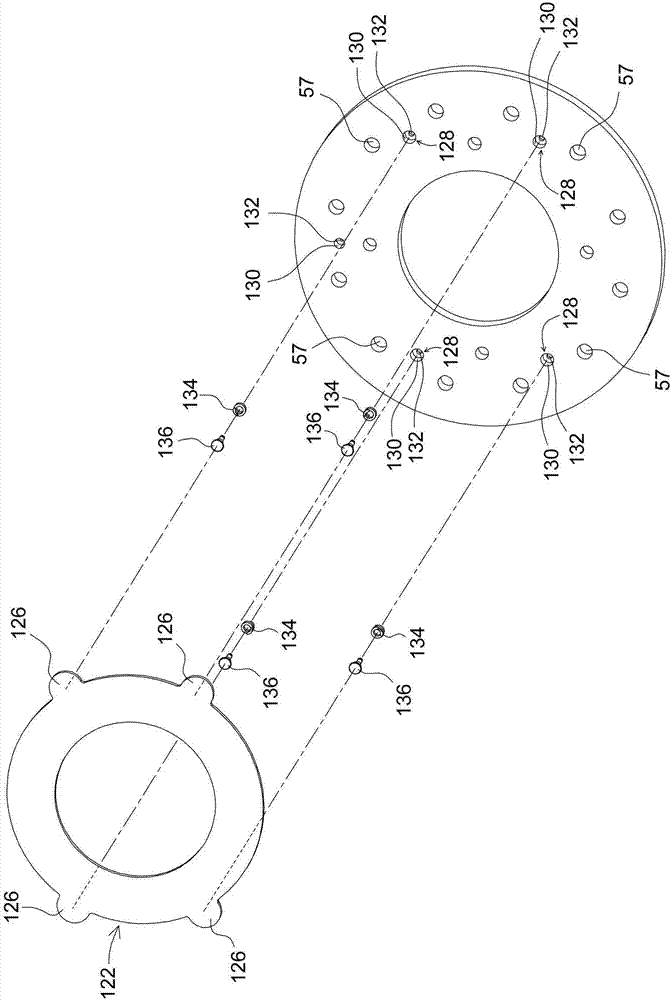

[0015] can be obtained by referring to the attached Figure 1 to Figure 5 To appreciate at least one example implementation of the disclosed subject matter.

[0016] now refer to figure 1 , shows a final drive 10 comprising a bell hub 12 and a spindle 14 comprising an annular mounting flange 16 comprising a plurality of mounting holes and Connected to and project radially from the inner end of a generally cylindrical section 18 of a spindle extending axially within the smaller end of the bell-shaped hub 12 . The spindle 14 is adapted to be mounted to a vehicle chassis (not shown) by inserting fasteners through mounting holes in the flange 16 .

[0017] The hub 12 is supported for rotation about the cylindrical section 18 of the mandrel by an axially inner tapered roller bearing 20 and an axially outer tapered roller bearing 22, respectively, wherein the inner end of the hub 12 is located radially outward of the inner roller bearing 20 and is supported by the shaft. An inwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com