Special-shaped ultra-high-molecular-weight polyethylene fiber textile fabric

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of textile fabrics, can solve the problems of expensive silk, cool minerals can not play an effective cool feeling, etc., to achieve the effect of improving anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

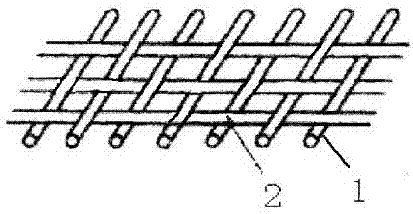

[0015] Such as figure 1 As shown, this embodiment provides a special-shaped ultra-high molecular weight polyethylene fiber textile fabric, which is woven from a warp yarn 1 and a weft yarn 2, and the warp yarn 1 adopts a composite yarn of a special-shaped cross-section ultra-high molecular weight polyethylene fiber and ordinary textile fibers. Composition, the weft yarn 2 is formed by twisting special-shaped ultra-high molecular weight polyethylene fibers. The common textile fiber composite yarn is one or three of chemical fibers such as polyester, viscose, polypropylene, PLA, nylon, and acrylic, or one of natural fibers such as cotton, linen, silk, and wool, or natural fibers One of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com