Deep thick muddy soft soil layer vacuum pipe well precipitation construction structure and construction method thereof

A silt, vacuum tube technology, applied in infrastructure engineering, construction, etc., can solve the problems of high water content, high construction risk, and difficulty in large-scale investment in large-scale equipment, and achieve the effect of reducing water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with accompanying drawing and embodiment:

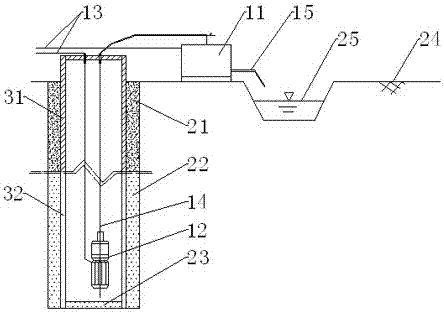

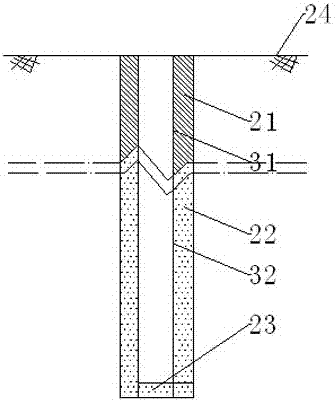

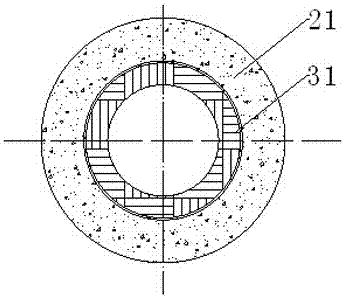

[0041] Such as Figure 1-3 As shown, a vacuum tube well dewatering construction structure in a deep muddy soft soil layer includes a dewatering well, the upper end of the dewatering well is covered with a steel pipe 31, the outer side of the steel pipe 31 is filled with cohesive soil 21, and the lower end of the dewatering well is covered with Steel pipe filter pipe 32, the outer side of steel pipe filter pipe 32 is filled with medium and coarse sand filter material 22, and the outer side of steel pipe filter pipe 32 is wrapped with 80 mesh filter screens.

[0042] Both the steel pipe real pipe 31 and the steel pipe filter pipe 32 are steel pipes with a diameter of 273 mm and a wall thickness ≥ 3.0 mm. In this embodiment, the steel pipe filter pipe 32 has a height of 9m.

[0043] The top of the dewatering well is sealed, and the bottom of the dewatering well is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com