Composite board unit body, curtain wall system thereof and installing technology

A technology of unit body and composite panel, which is applied in the direction of walls, building components, buildings, etc., and can solve the problems of increasing cycle, inability to align plates, poor installation flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

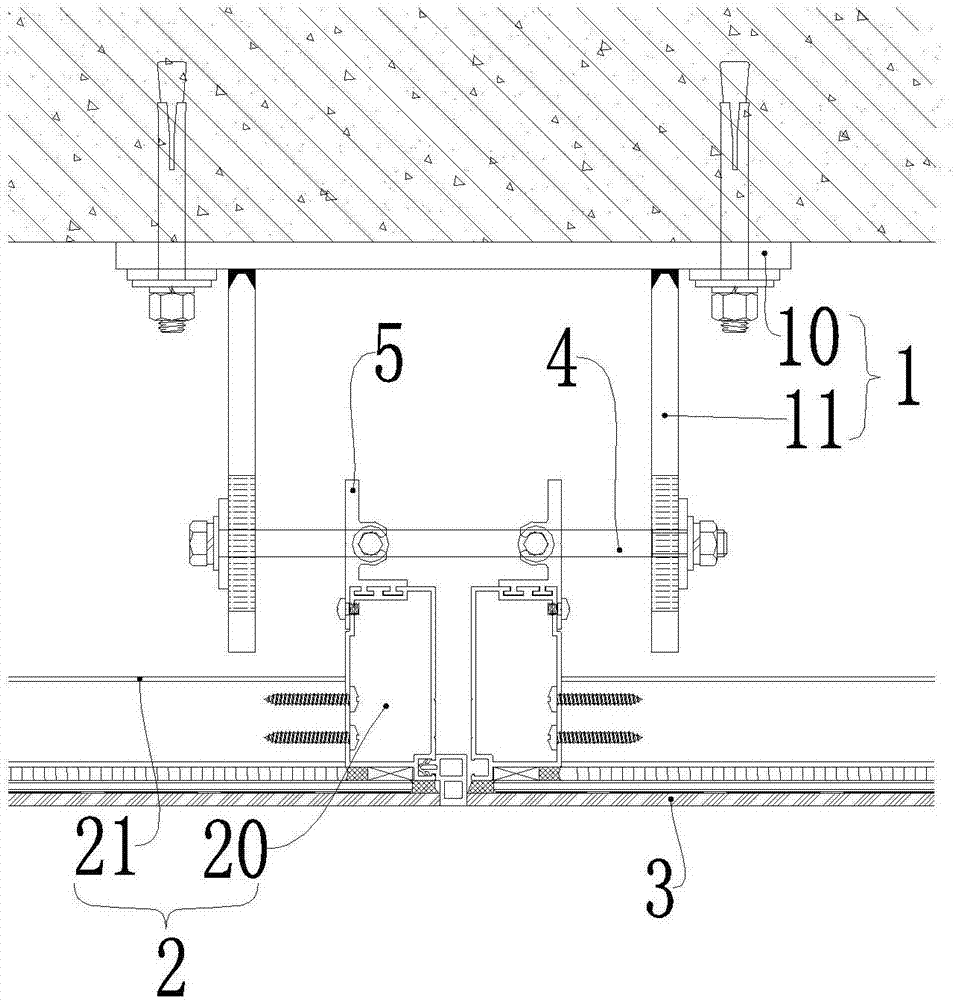

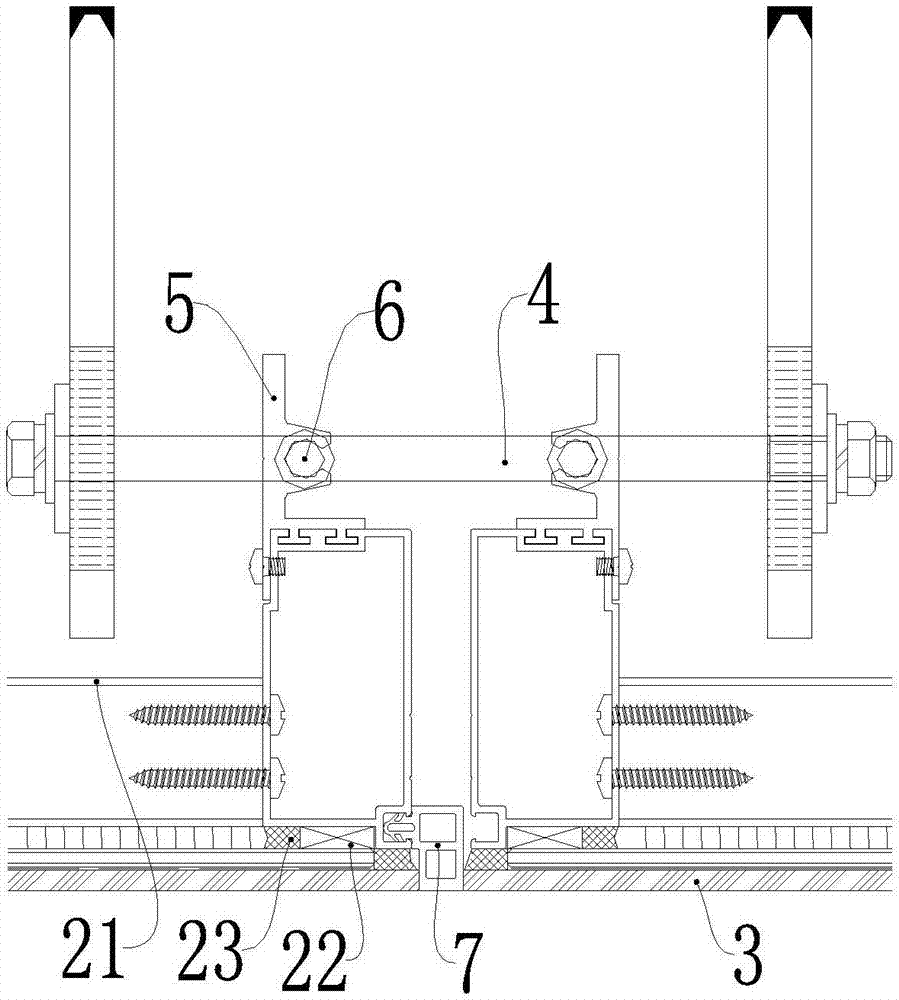

[0034] like Figure 1-Figure 3 As shown, a composite plate unit body includes a fixing assembly 2 and a glass composite ceramic sheet 3, and the fixing assembly 2 is glued to the glass composite ceramic sheet 3, and also includes a support bolt 4, a pendant 5 and an adjusting screw 6;

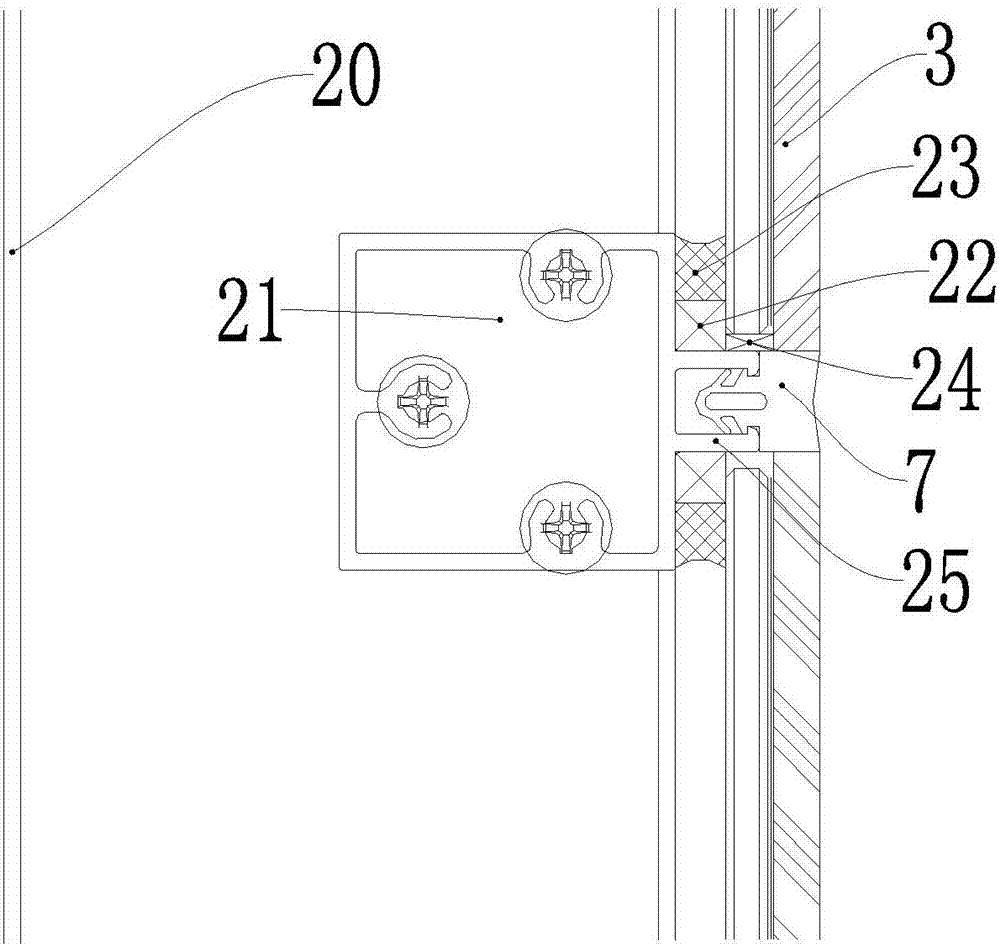

[0035] The fixing assembly 2 includes a vertical keel 20 and a horizontal keel 21; the vertical keel 20 and the horizontal keel 21 are fixed into a frame; every two glass composite ceramic sheets 3 are glued to the frame and fixed into a unit body; The rear end of the vertical keel 20 is provided with a groove corresponding to the pendant 5, and the pendant 5 is fastened in the groove and installed on the rear end of the vertical keel 20; The through hole of the adjustment screw 6, the adjustment screw 6 is installed in the through hole; the unit body is installed on the support bolt 4 through the hanger 5, and the support bolt 4 is arranged transversely, and the The glass-composite ceramic th...

Embodiment 2

[0065] like Figure 4-6 As shown in the figure, the structure and principle of a seamless composite panel unit body is basically the same as that of a slotted composite panel unit body in Example 1, and the installation steps are basically the same. Each adjacent glass composite ceramic sheet 3 of the slot-type composite plate unit body is tightly connected and assembled, and there is no gap between the plates. Compared with the slotted composite panel unit, the overall effect of the installation is more beautiful, and the two systems can meet the needs of different customers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com