Vortex compressor

A scroll compressor and compression chamber technology, applied in the field of compressors, can solve the problems of reducing the viscosity of lubricating oil, reducing the lubricating effect, reducing the energy efficiency of the compressor, etc. The effect of small frictional power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

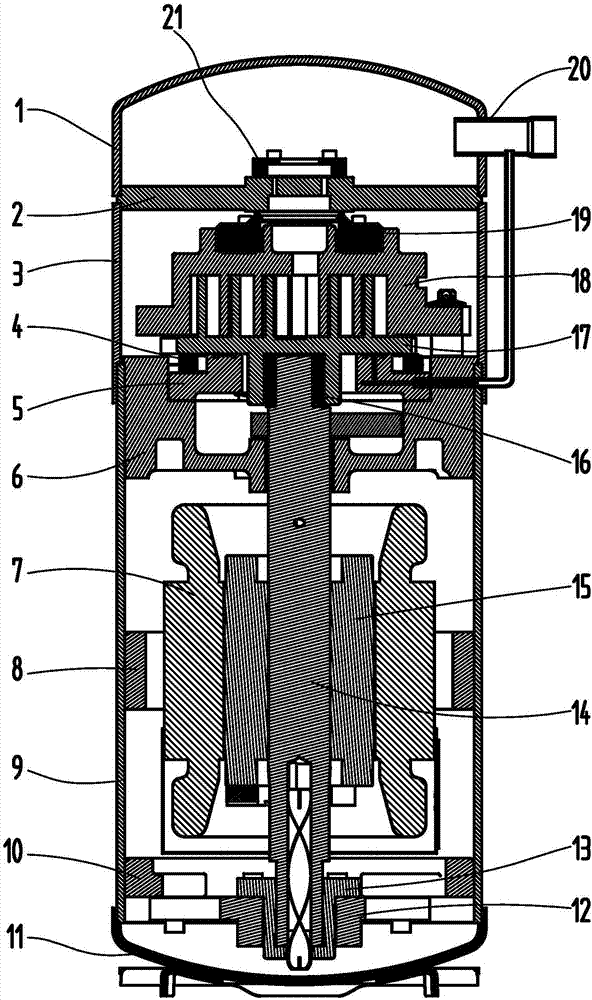

[0037] Before proceeding to describe the main features of the scroll compressor of the present invention in detail, first in conjunction with figure 1 The general characteristics of this scroll compressor will be described.

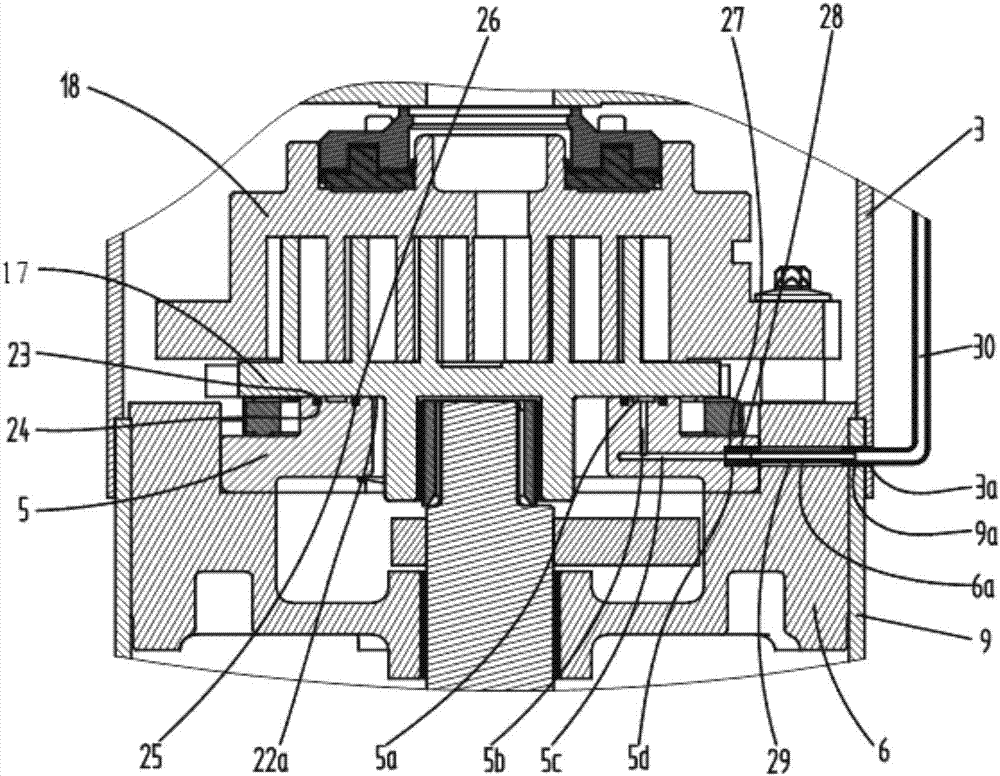

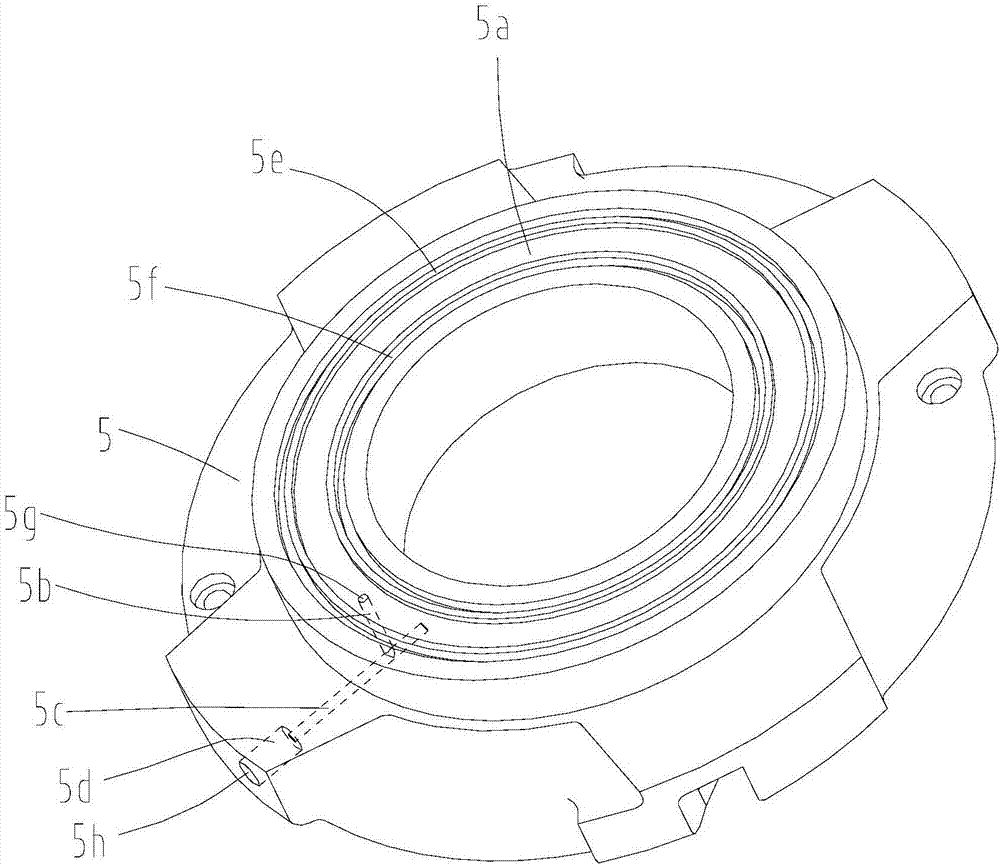

[0038] Such as figure 1 As shown, the scroll compressor mainly includes a motor 7, an upper bracket 6, a lower bracket 12, a fixed scroll 18, a movable scroll 17, an Oldham slip ring 4, a crankshaft 14, and the like. The motor 7 is fixed on the lower casing 9 through the motor fixing frame 8, and the upper bracket 6 is fixed on the lower casing 9 through an interference fit and an axial thrust structure. The movable scroll 17 and the fixed scroll 18 are opposed to each other with a phase angle difference of 180 degrees, and the movable scroll 17 is installed on the upper bracket 6 and supported by the support plate 5, and the support plate 5 is installed on the upper bracket 6, and passes through Screws are fixed on the upper bracket 6, and the upper br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com