Double-way mechanical seal ring

A mechanical seal and sealing ring technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of insufficient opening force of the end face, insufficient rotation selectivity, poor anti-interference performance, etc. The effect of simple structure design and high rigidity of air film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

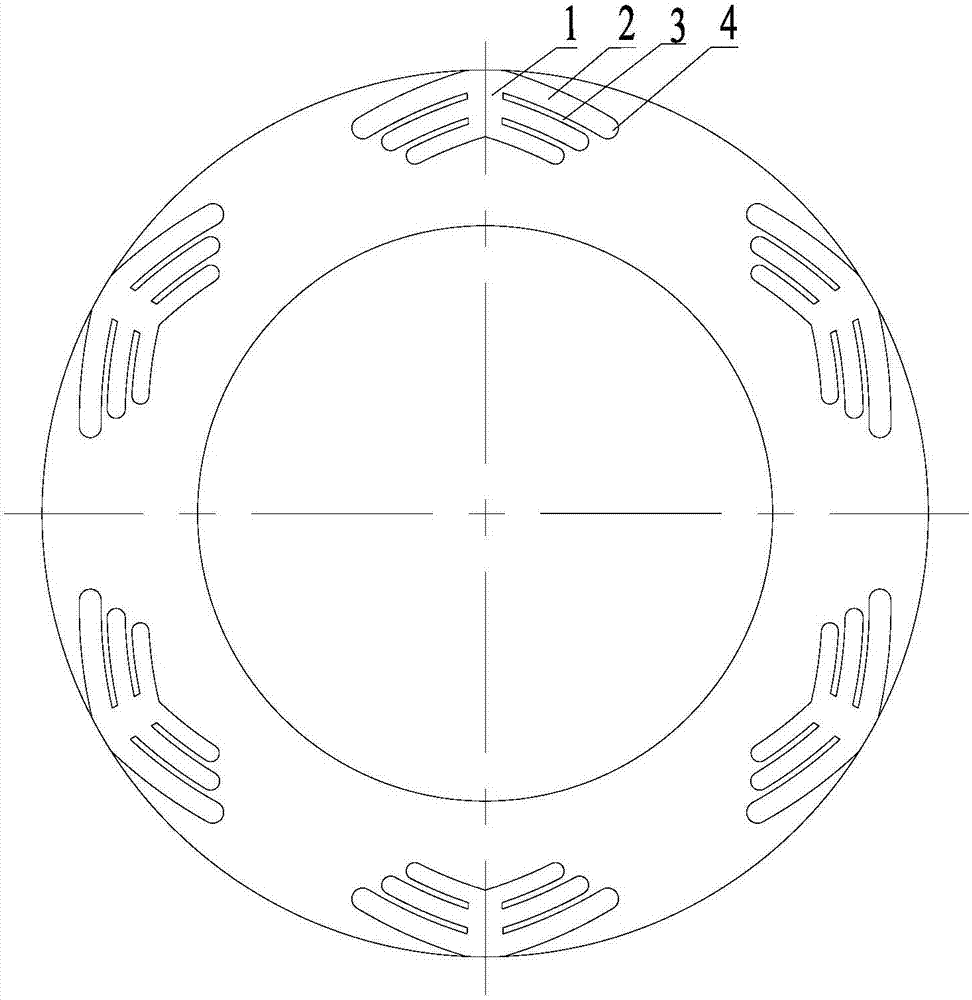

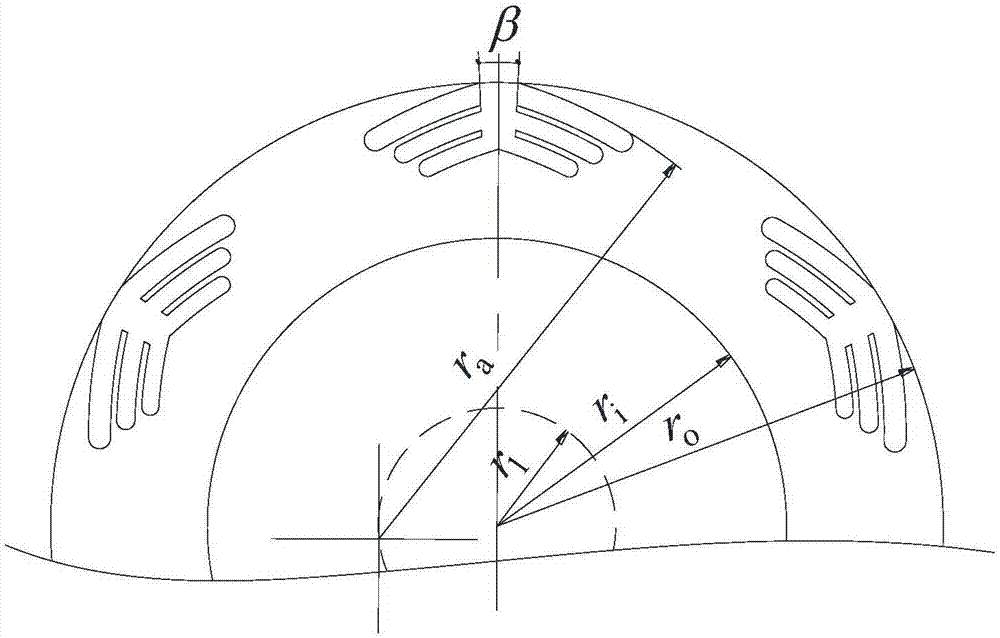

[0042] As attached to the manual figure 1 , 2 As shown in and 3, a two-way mechanical seal ring includes two seal rings of the mechanical seal, that is, a moving ring and a static ring; the end face of the moving ring is provided with six imitation finger-shaped grooves evenly distributed in the circumferential direction; each imitation The finger-shaped grooves are composed of an air inlet groove 1 distributed radially along the sealing ring, and left and right finger-shaped grooves 2 respectively connected to both sides of the air inlet groove 1; the air inlet groove 1 is composed of two air inlet grooves distributed radially along the sealing ring The straight line is composed of a straight line, and the extension line of the straight line inward passes through the rotary shaft of the seal ring, and the extension line of the straight line passes through the intersection of the outermost side of the finger groove 2 and the outer circle of the seal ring; the left and right fi...

Embodiment 2

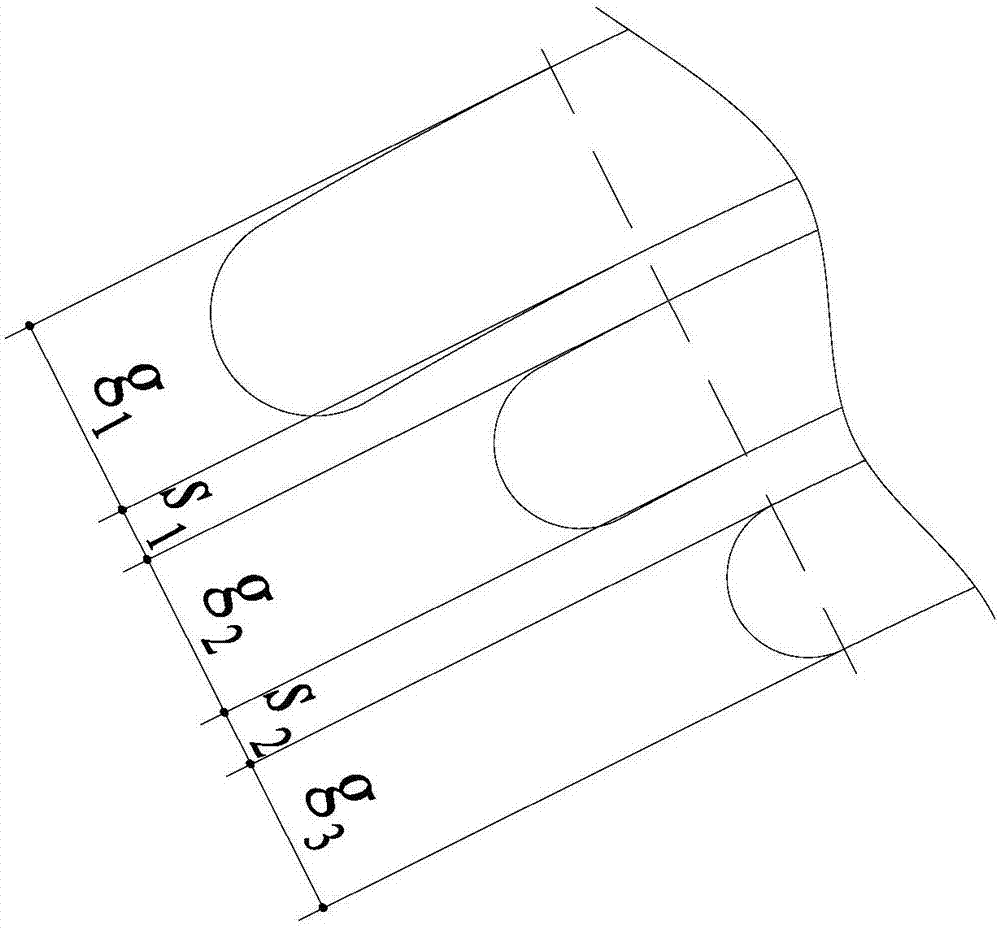

[0051] As attached to the manual Figure 4 As shown, the difference between the two-way mechanical seal ring described in Example 2 and the two-way mechanical seal ring described in Example 1 is that the end surface of the moving ring is provided with eight finger-like grooves evenly distributed in the circumferential direction; In each finger-like groove, there are two rows of left and right finger-shaped grooves 2, which are distributed along the radial direction of the sealing ring, and are symmetrical about the central axis of the air inlet groove 1; The grooves 2 are separated by an ungrooved sealing weir 4; the radius r of the outer circle of the sealing ring o =80mm, the radius r of the inner hole of the sealing ring i =55mm; the groove depths of all finger-shaped grooves in each finger-shaped groove are equal, and the groove depth is 5 μm; the angle β between the two straight lines forming the air inlet groove is 8°; for the same finger-shaped groove, the same The ar...

Embodiment 3

[0057] As attached to the manual Figure 5 As shown, the difference between the two-way mechanical seal ring described in Embodiment 3 and the two-way mechanical seal ring described in Embodiment 1 is that the end surface of the moving ring is provided with seven finger-like grooves evenly distributed in the circumferential direction; In each finger-like groove, there are three rows of left and right finger-shaped grooves 2, all distributed along the radial direction of the sealing ring, and the left and right finger-shaped grooves 2 are asymmetrical; the left and right finger-shaped grooves 2 are asymmetrical, specifically shown as a The depth of the side groove is 5 μm, and the arc length is 19.5-24.5 mm (main groove), and the depth of the groove on the other side is 3 μm, and the arc length is 7.5-15.5 mm (protective groove).

[0058] In the process of applying the two-way mechanical seal ring described in this example, during normal operation, when the direction of rotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com