Parameter Calibration Method of Ultrasonic Focusing Probe

A technology of parameter calibration and ultrasonic focusing, which is used in material analysis, instruments, and measuring devices using sonic/ultrasonic/infrasonic waves. and other problems to achieve the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (a) Prepare a standard sample 4 for ultrasonic testing, the material of which is aluminum, and its acoustic reflection coefficient R(θ) can be obtained by measurement or calculation. Standard sample 4 is prepared as a regular cuboid or cylinder, and its test surface has sufficient reflection area and sufficient depth (generally greater than 50 mm); the test surface roughness of standard sample 4 is not less than Ra 0.8 μm. A point-focused probe is used to measure the acoustic characteristic curve of the standard sample.

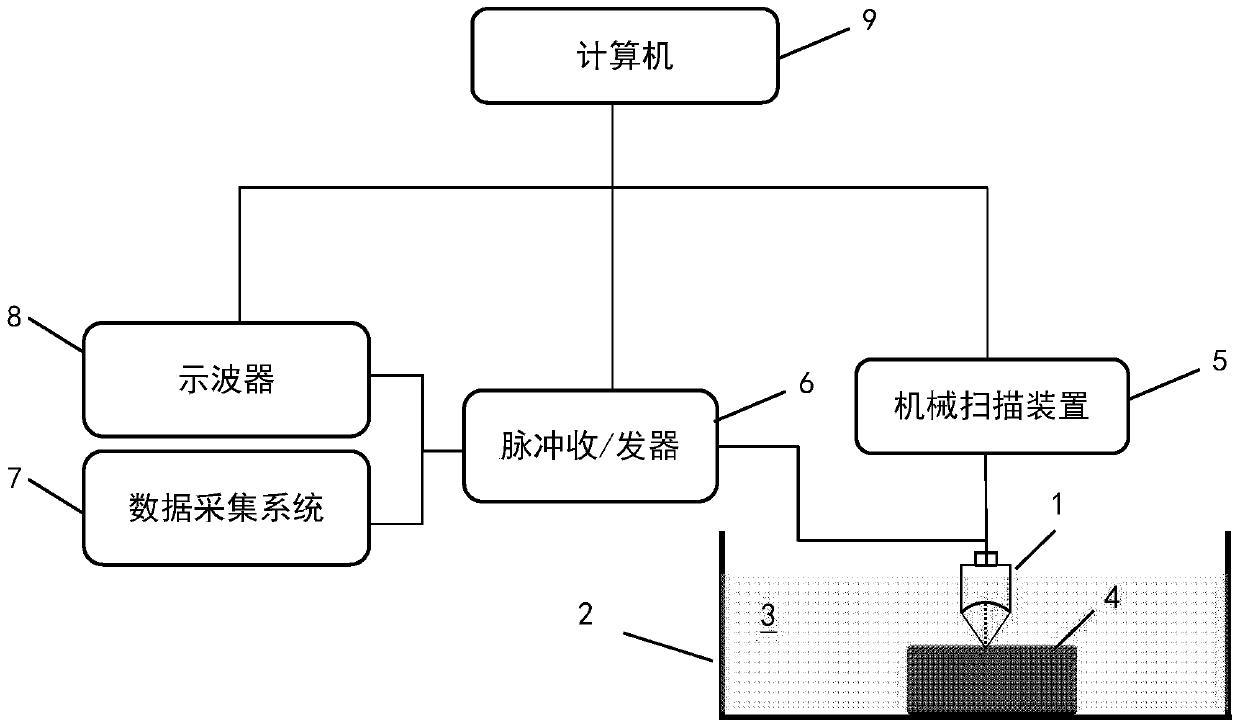

[0040] (b) Put standard sample 4 into figure 1 In the working tank 2 of the ultrasonic microscope equipment shown, the working tank 2 uses clean, bubble-free water 3 as a coupling agent. Adjust the mechanical scanning device 5 , and then adjust the direction of the point focusing probe 1 , so that the axial direction of the point focusing probe 1 is kept perpendicular to the reflective surface of the standard sample 4 .

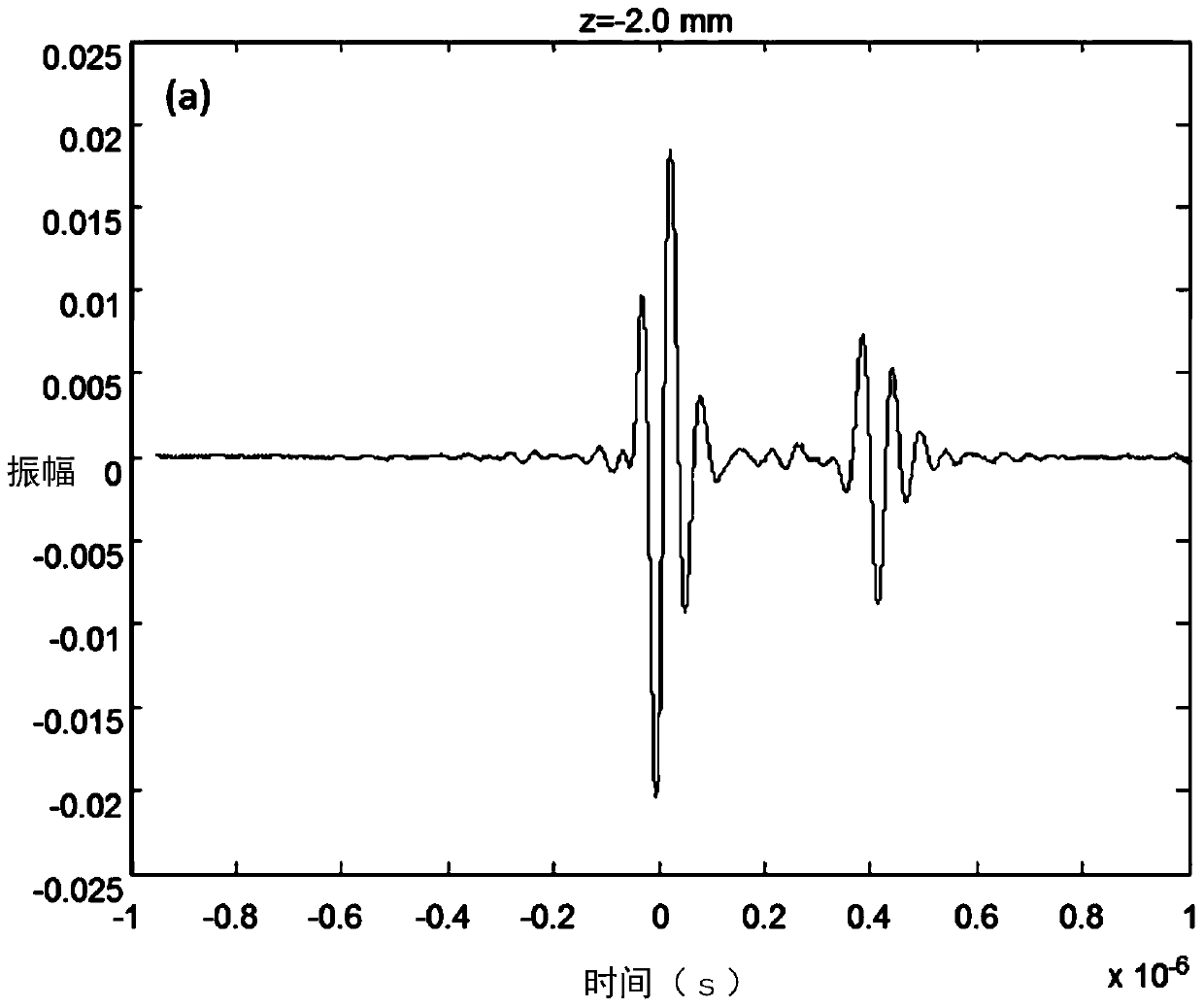

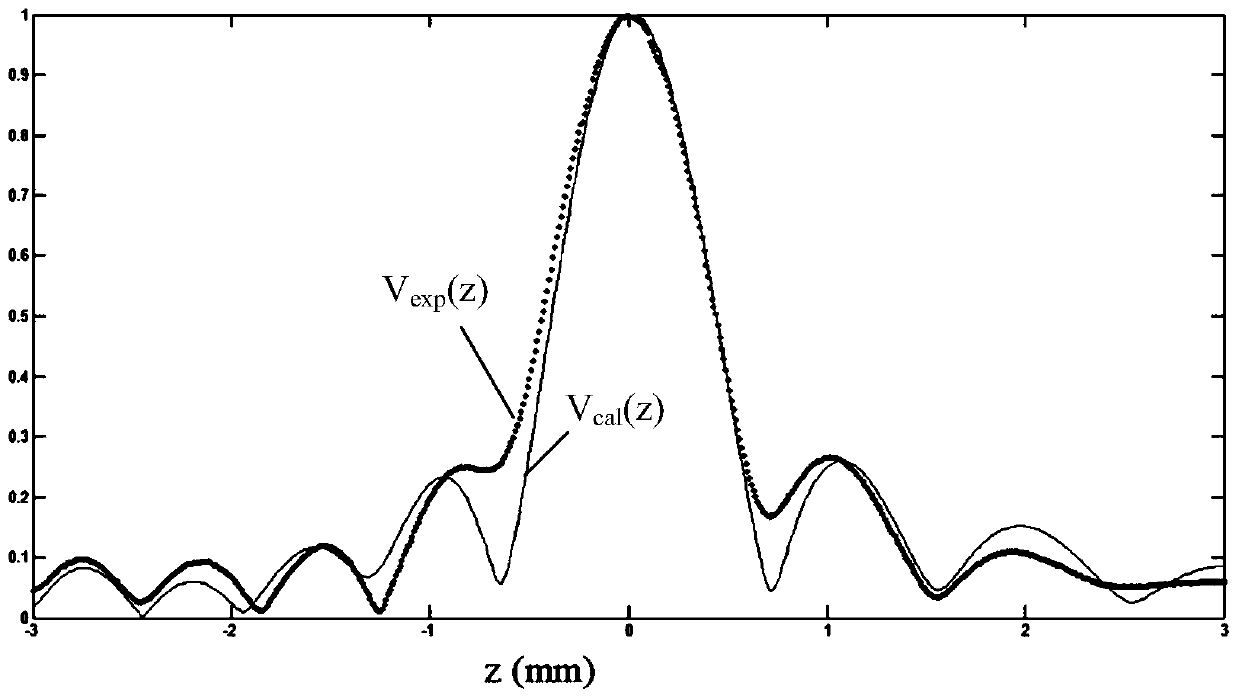

[0041] (c) Adjust the positi...

Embodiment 2

[0053] (a) Prepare a standard sample for ultrasonic testing. The material of the standard sample is Inconel600, and its acoustic reflection coefficient R(θ) can be obtained by measurement or calculation. The standard sample is prepared as a regular cuboid, and its test surface has sufficient reflection area and sufficient depth (generally greater than 50 mm); the test surface roughness of the standard sample is not less than Ra 0.4 μm; the acoustic characteristics of the standard sample are measured by a line focusing probe curve measurement.

[0054] (b) Put standard sample 4 into figure 1 In the working tank 2 of the ultrasonic microscope equipment shown, the working tank 2 uses clean, bubble-free water 3 as a coupling agent. Adjust the mechanical scanning device 5 to make the direction of the line focusing probe 1 so that the axial direction of the line focusing probe 1 is kept perpendicular to the reflective surface of the standard sample 4 .

[0055] (c) Use the mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap