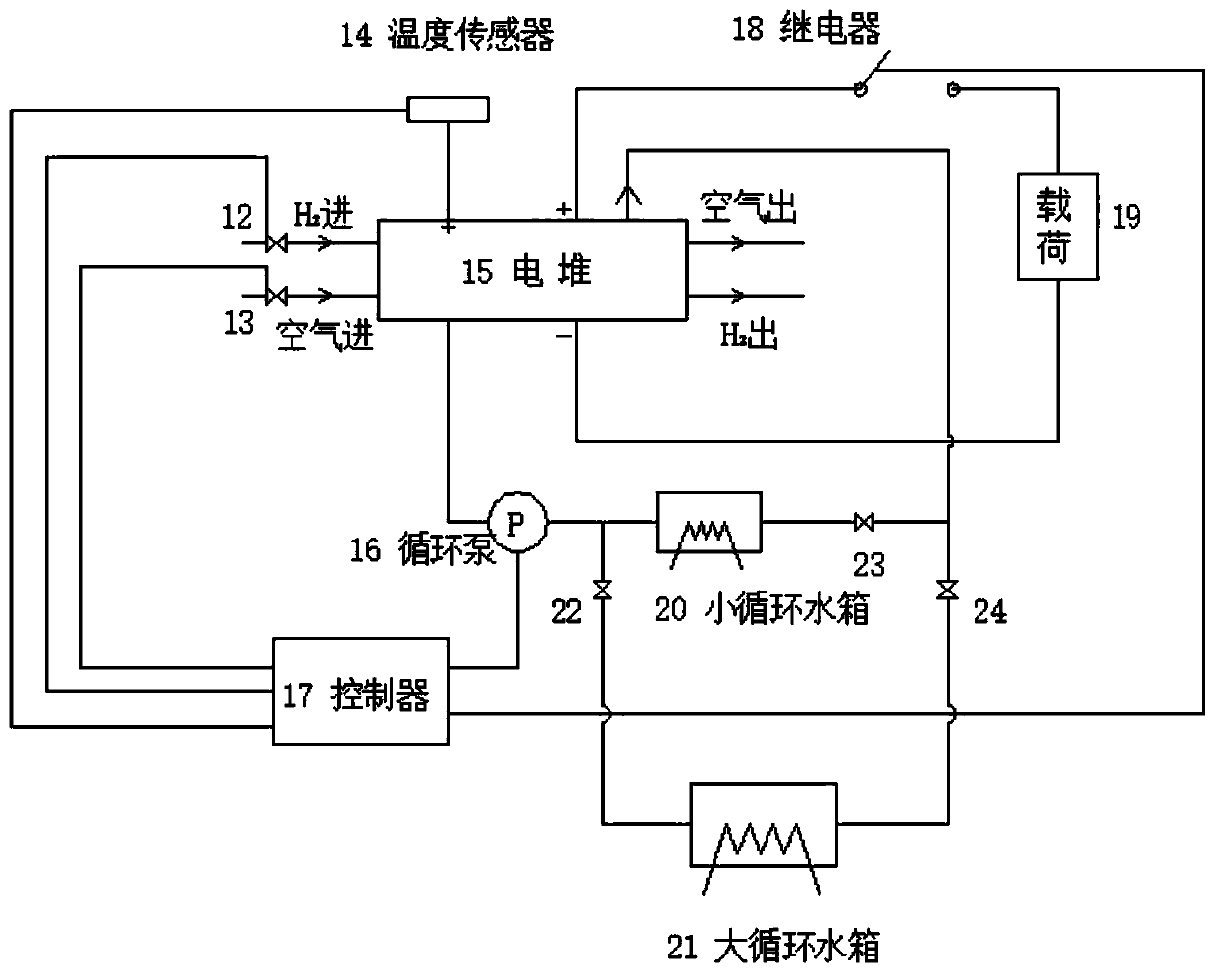

A kind of pem stack and system for cold start staged preheating

A technology of graded preheating and cold start, applied in circuits, fuel cells, electrical components, etc., can solve the problems of preheating without considering the stack and system heat insulation structure, slow preheating speed, and large preheating energy consumption. , to achieve the effect of simple and reliable structure, reducing secondary damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

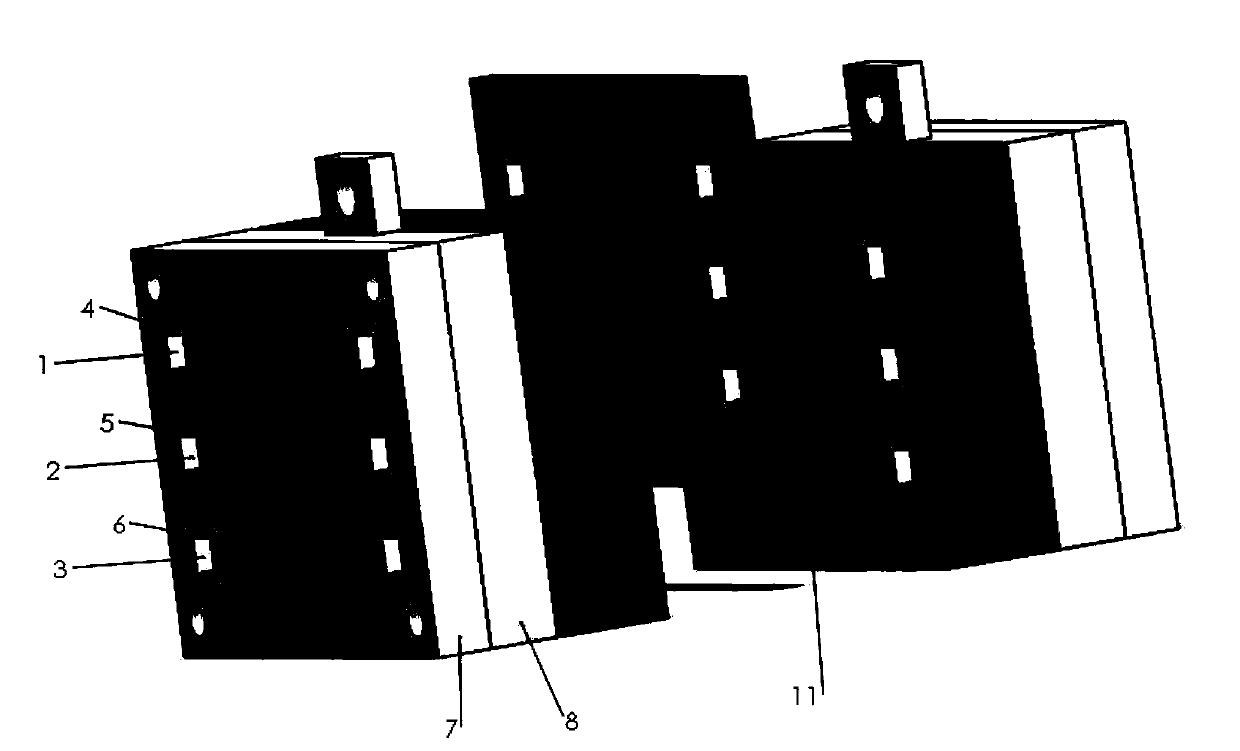

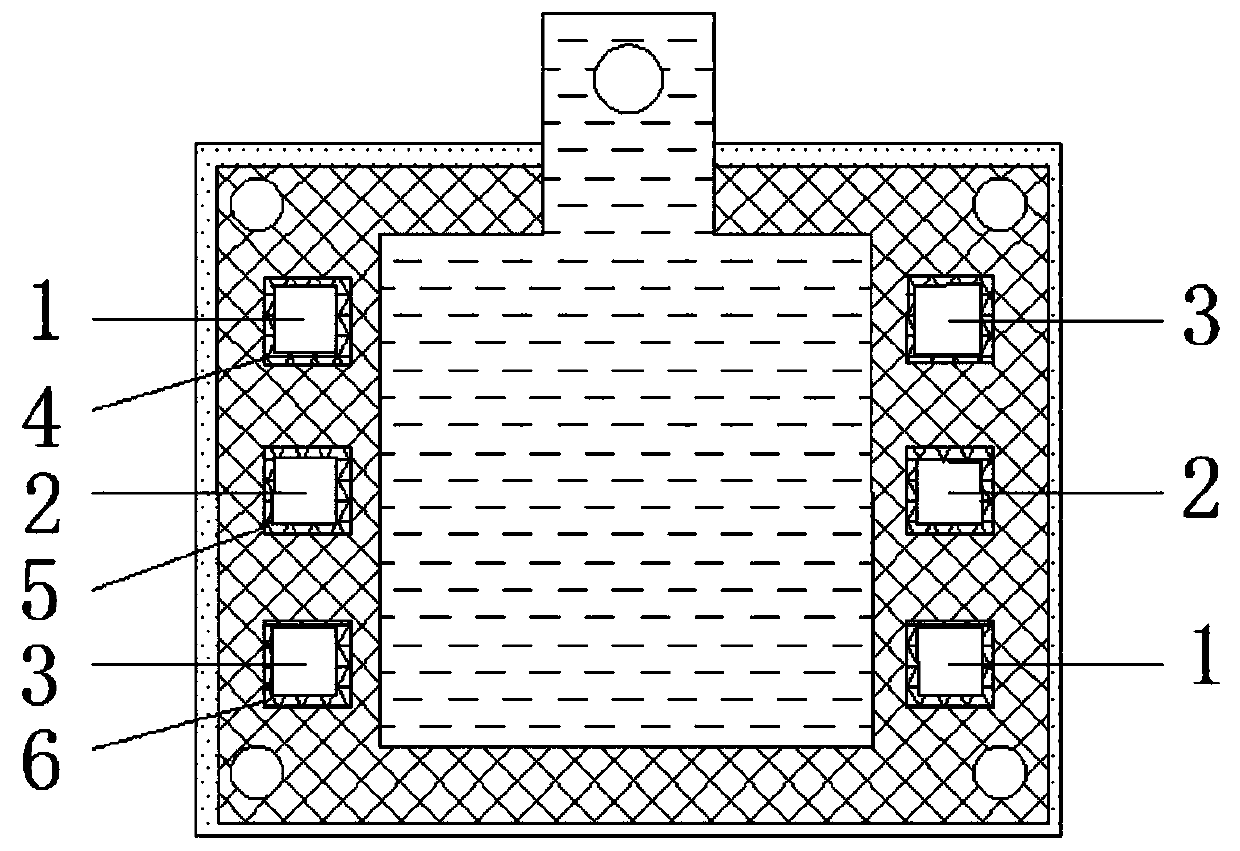

Embodiment 1

[0051] MEA active area is 280cm 2 The 30kW metal bipolar plate stack is assembled by 150 single cells 11, the clamping end plate 7 is made of stainless steel, the insulating plate 8 is made of epoxy plate, the heat insulation structure 9 is made of thermal insulation material, and the current collecting plate 10 is made of gold-plated copper plate , the small circulating coolant is estimated to be 10L. When the temperature rises from -30°C to -10°C or from -20°C to 0°C, the heat required by component 1, component 2 and component 3 is 220kJ, 136kJ and 840kJ respectively.

[0052] In the appropriate temperature range, the stack runs self-heating. In order to increase the calorific value, the operating voltage of the single chip is 0.1V, and the current is estimated to be 100mA / cm2. The calorific value and output power W are respectively

[0053] Q=150*280*100mA / cm 2 *(1.25-0.1)V=4.83kW,

[0054] W=150*280*100mA / cm 2 *0.1V=420W,

[0055] Utilizing the heat insulation grouping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com