Control system of laser

A control system and laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as uncontrollable software board connection, increased hardware costs, compatibility issues, etc., to achieve powerful internal resources and image processing Ability, high performance, cost-effective, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

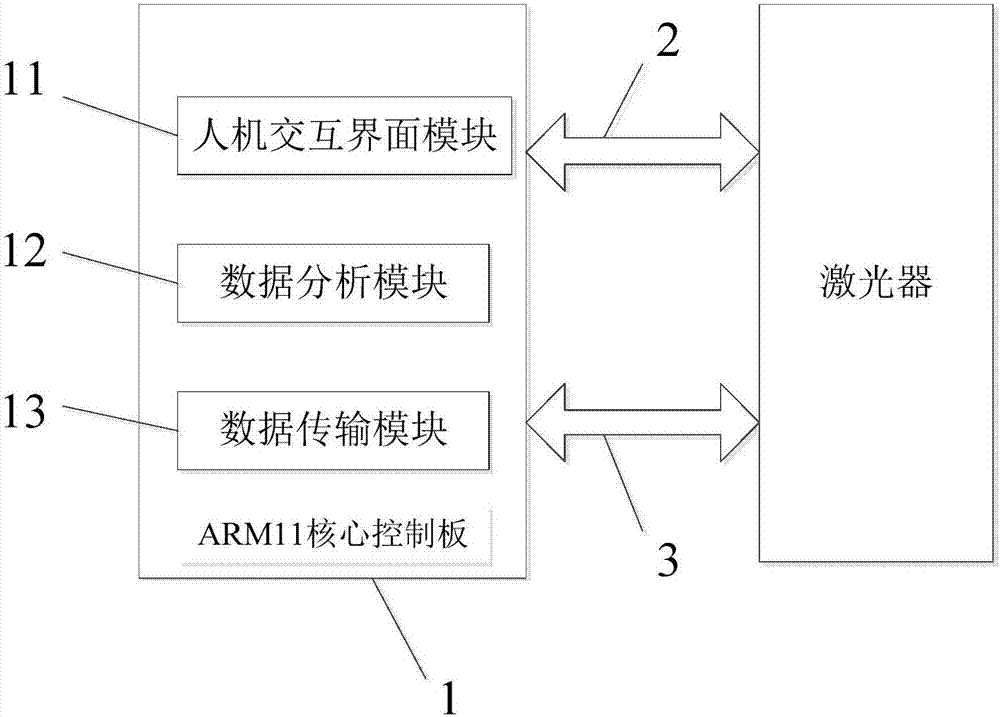

[0018] Such as figure 1 As shown, the present invention discloses a laser control system, including ARM11 core control board 1, serial data communication interface 2 and parallel data communication interface 3, ARM11 core control board 1 includes human-computer interaction interface module 11, data analysis module 12 and data transmission module 13,

[0019] The human-computer interaction interface module 11 is used to issue control instructions to the laser and display the implementation of the laser feedback;

[0020] The data analysis module 12, the data analysis module 12 is used for analyzing and storing the laser control instructions sent by the man-machine interaction interface module 11; the data analysis module 12 processes the execution situation of the received laser feedback, and displays the processing results on the man-machine On the interactive interface module 11, the data analysis module 12 is connected with the serial data communication interface 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com