Chafing dish bottom material and preparation method thereof

A hot pot base and spice technology, which is applied in the directions of food ingredients containing natural extracts, functions of food ingredients, food science, etc., can solve problems such as affecting people's health, diarrhea, etc. Discomfort, flexible operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

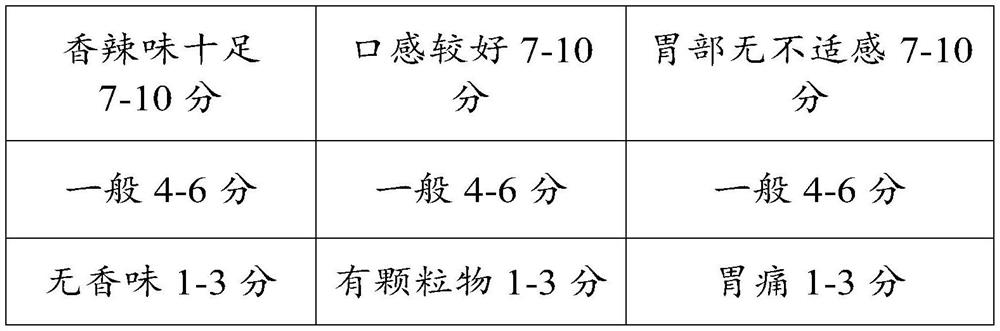

Image

Examples

Embodiment 1

[0042] This embodiment provides a kind of chafing dish bottom material, is made through the following steps:

[0043] Take 80 parts of butter, 60 parts of pepper, 20 parts of bean paste, 2 parts of Chinese prickly ash, 15 parts of salt, 5 parts of ginger, 2 parts of garlic, 1 part of brown sugar, 2 parts of tempeh, 2 parts of monosodium glutamate, 2 to 6 parts of spirulina, spare.

[0044] Melt the butter at 130°C to form hot oil, wash, dry, and crush the chili, pepper, ginger, and garlic for later use; chop the garlic and ginger, and brew them with boiling water to make the garlic and ginger The taste is better revealed, increasing the fragrance of the hot pot base.

[0045] At 100°C, add chili, bean paste, pepper, ginger, garlic, brown sugar, salt, monosodium glutamate and fermented soybeans to the hot oil, and stir fry for 10 minutes for the first time.

[0046] Then add spirulina, stir-fry for the second time at 90° C. for 5 minutes, and then boil for 1 hour. During the...

Embodiment 2

[0048] This embodiment provides a kind of chafing dish bottom material, is made through the following steps:

[0049] Weigh 40 parts of Bletilla striata, 30 parts of Atractylodes macrocephala, 10 parts of yam, 10 parts of hawthorn, 20 parts of gallinaceae, 20 parts of astragalus, 20 parts of malt, 10 parts of gorgon, 20 parts of Huoxiang and 20 parts of tangerine peel. After washing, it is crushed to help extract the active ingredients in the raw materials.

[0050] Mix the crushed raw materials with water, soak for 20 minutes, and the cold water is generally 10°C.

[0051] After soaking, boil with strong fire, then decoct with slow fire for 25 minutes, filter to get the first filtrate; wherein, strong fire is 300-400°C, and slow fire is 130-170°C.

[0052] Add appropriate amount of water to the filtered medicinal dregs, boil with strong fire, then decoct with slow fire for 15 minutes, filter to get the second filtrate; combine the first and second filtrates, concentrate and ...

Embodiment 3

[0058] This embodiment provides a kind of chafing dish bottom material, is made through the following steps:

[0059] Weigh 45 parts of Bletilla striata, 35 parts of Atractylodes macrocephala, 15 parts of Chinese yam, 15 parts of hawthorn, 25 parts of gallinaceae, 25 parts of astragalus, 25 parts of malt, 15 parts of gorgon, 25 parts of Huoxiang and 25 parts of tangerine peel. After washing, it is crushed to help extract the active ingredients in the raw materials.

[0060] Mix the crushed raw materials with water, soak for 25 minutes, and the cold water is generally 20°C.

[0061] After soaking, boil with strong fire, then decoct with slow fire for 30 minutes, filter to get the first filtrate; wherein, strong fire is 300-400°C, and slow fire is 130-170°C.

[0062] Add appropriate amount of water to the filtered medicinal dregs, boil with strong fire, then decoct with slow fire for 20 minutes, filter to get the second filtrate; combine the first filtrate and the second filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com