a soy milk machine

A soymilk machine and machine head technology, applied in kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of not beautiful appearance, unfavorable cleaning, easy storage of slag, etc., and achieve easy cleaning, convenient cleaning, reliability and stability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

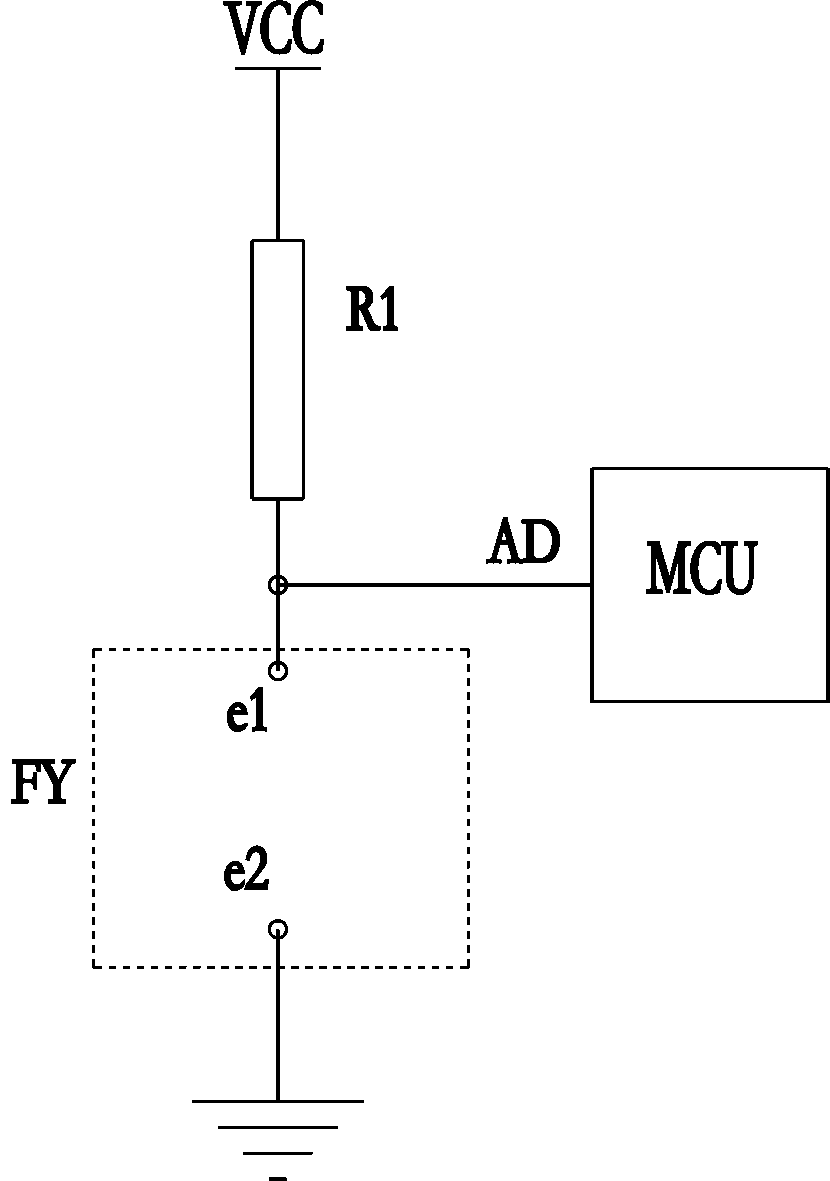

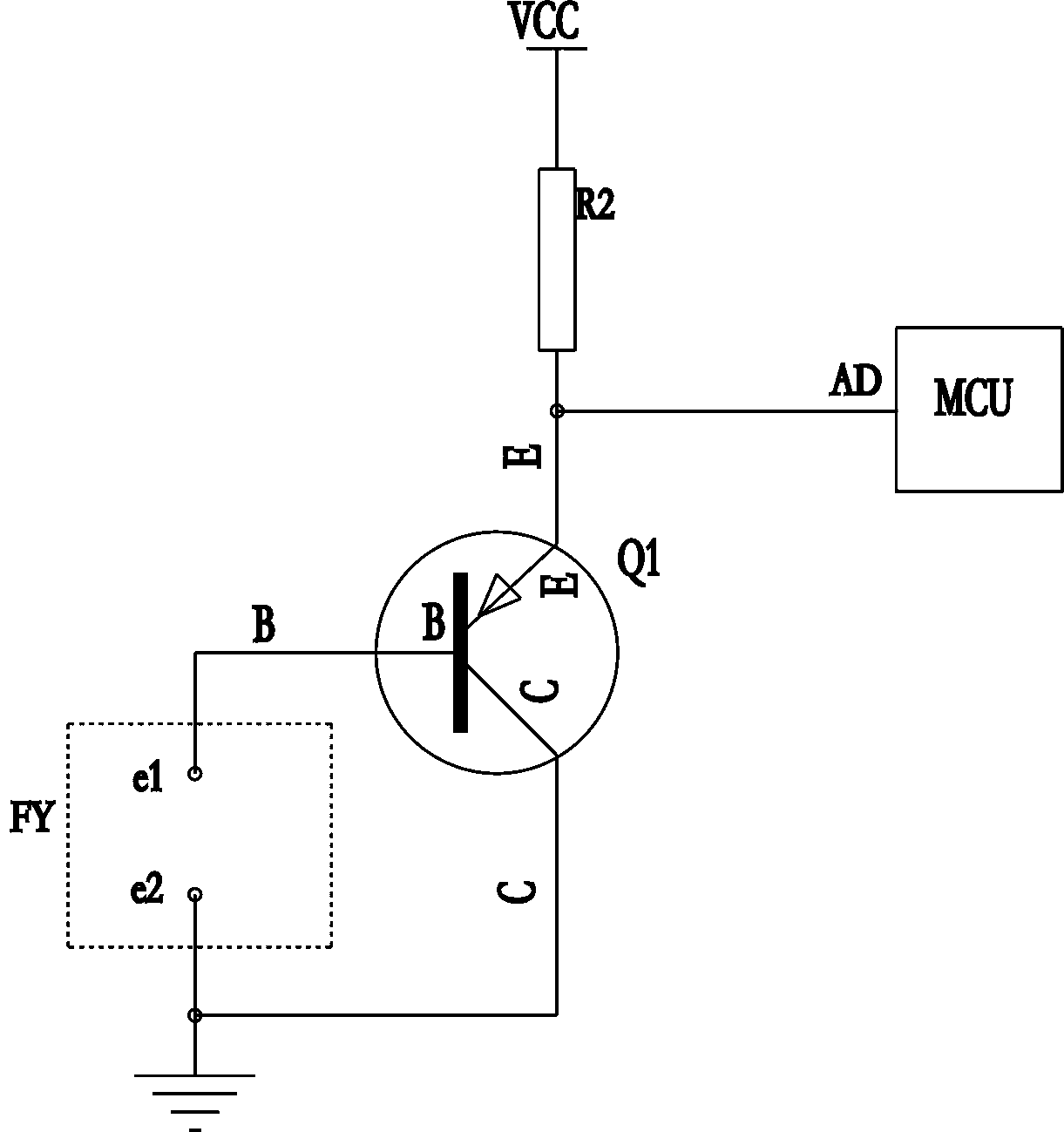

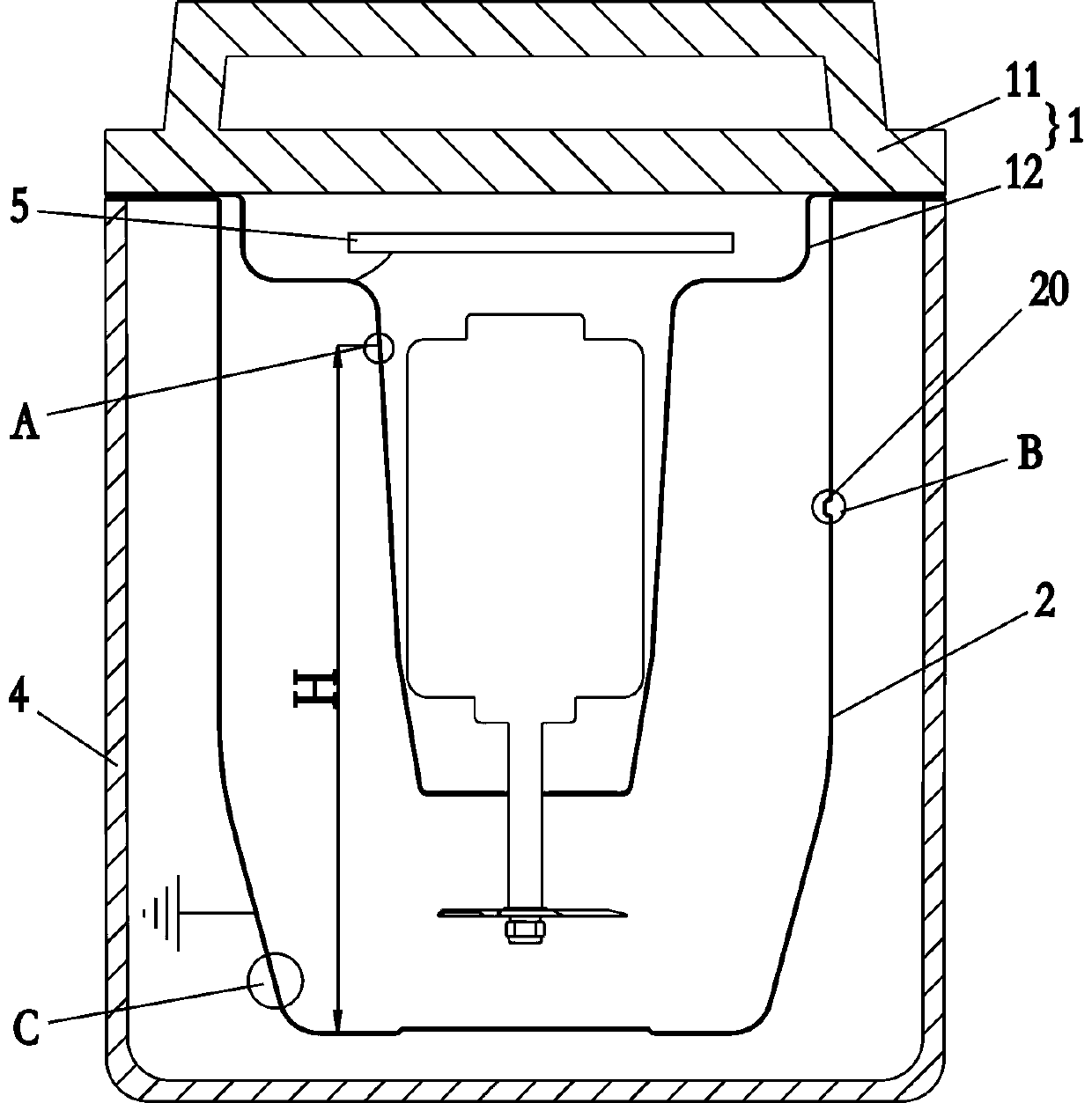

[0035] Such as image 3 , Figure 4 , Figure 5 , Image 6 Shown is a schematic structural diagram of the first embodiment of the present invention. A soymilk machine, comprising a machine head 1 and a cup body, the machine head 1 comprising a machine head upper cover 11 and a metal lower cover 12, the machine head has no anti-overflow electrode rod, and the cup body is provided with a water level indicator Line 20, the outer wall of the lower metal cover 12 has a first covering area 121 covered by an insulating non-stick coating and a first hollow area not covered by the insulating non-stick coating. The first hollow area is located at the water level marking line Above 20, the first hollow area forms an anti-overflow detection electrode, the cup body is provided with a conductive electrode, the conductive electrode is located below the water level marking line 20, the slurry rises to connect the conductive electrode with the anti-overflow detection electrode, Realize the dete...

Embodiment 2

[0050] Such as Figure 7 , Figure 8 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that: in this embodiment, the bottom wall of the metal cup 2 is provided with a through hole 23, and the conductive electrode passes through the through hole 23 and is exposed to the conductive inside the metal cup 2. The column 3 is a sealed fit between the conductive column 3 and the through hole 23.

[0051] In this embodiment, the conductive column 3 includes a top brim 31 and a connecting column 32 integral with the hat brim 31. The bottom of the brim 31 has an annular groove 33 arranged around the connecting column 32. The connecting column A sealing ring 6 is sleeved on 32, and the sealing ring 6 is clamped in the annular groove 33 by the brim 31 and the bottom wall of the metal cup body 2. At the same time, an annular clamping groove 60 is provided on the outer side of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com