Horizontal spiral centrifuge

A decanter centrifuge and centrifuge technology are applied in centrifuges, centrifuges with rotary drums, etc., and can solve the problems of failing to meet process requirements, high solid content, and unimproved solid-liquid separation effect, etc. Achieve the effect of strengthening sedimentation and thorough solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

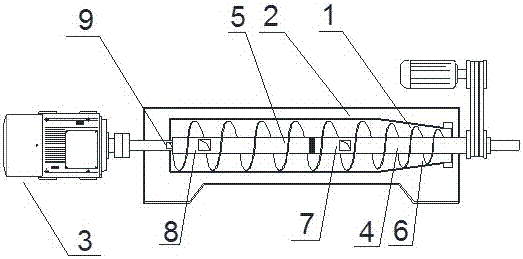

[0031] Embodiment 1: a horizontal screw centrifuge, comprising a screw pusher 1, a drum 2 and a motor 3, the motor 3 is used to drive the drum 2 and the screw pusher 1 to rotate coaxially and in the same direction at a preset speed difference, There is a cavity in the drum 2, the central axis of the screw feeder 1 and the drum 2 are the same straight line, the screw feeder 1 part is located inside the drum 2, and the screw feeder 1 includes a discharge part 4 and a discharge The integral part formed by the liquid part 5 and the screw blade 6, the inner diameter of the integral part formed by the discharge part 4 of the screw propeller 1 and the liquid discharge part 5 becomes smaller in the direction of the liquid discharge part 5, close to the wall of the drum 2, and the discharge The part 4 and the liquid outlet part 5 are all provided with a cavity, the discharge part 4 and the liquid part 5 are not connected, the discharge part 4 is provided with a discharge port 7, and the...

Embodiment 2

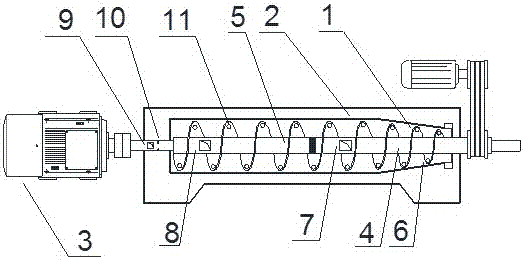

[0032] Embodiment 2: a horizontal screw centrifuge, comprising a screw pusher 1, a drum 2 and a motor 3, the motor 3 is used to drive the drum 2 and the screw pusher 1 to rotate coaxially and in the same direction at a preset speed difference, There is a cavity in the drum 2, the central axis of the screw feeder 1 and the drum 2 are the same straight line, the screw feeder 1 part is located inside the drum 2, and the screw feeder 1 includes a discharge part 4 and a discharge The integral part formed by the liquid part 5 and the screw blade 6, the inner diameter of the integral part formed by the discharge part 4 of the screw propeller 1 and the liquid discharge part 5 becomes smaller in the direction of the liquid discharge part, and the position close to the wall of the drum 2 becomes smaller, and the discharge part 4 and the liquid outlet 5 are provided with cavities, the discharge part 4 and the liquid outlet 5 are not connected, the discharge part 4 is provided with a disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com