Double-surface grinding machine for cylindrical wafer

A double-sided grinding and cylindrical crystal technology, which is applied in the direction of grinding machine tools, grinding devices, working carriers, etc., can solve the problems of unfavorable production, increased production costs, and low utilization of star wheels, so as to improve versatility and facilitate production and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

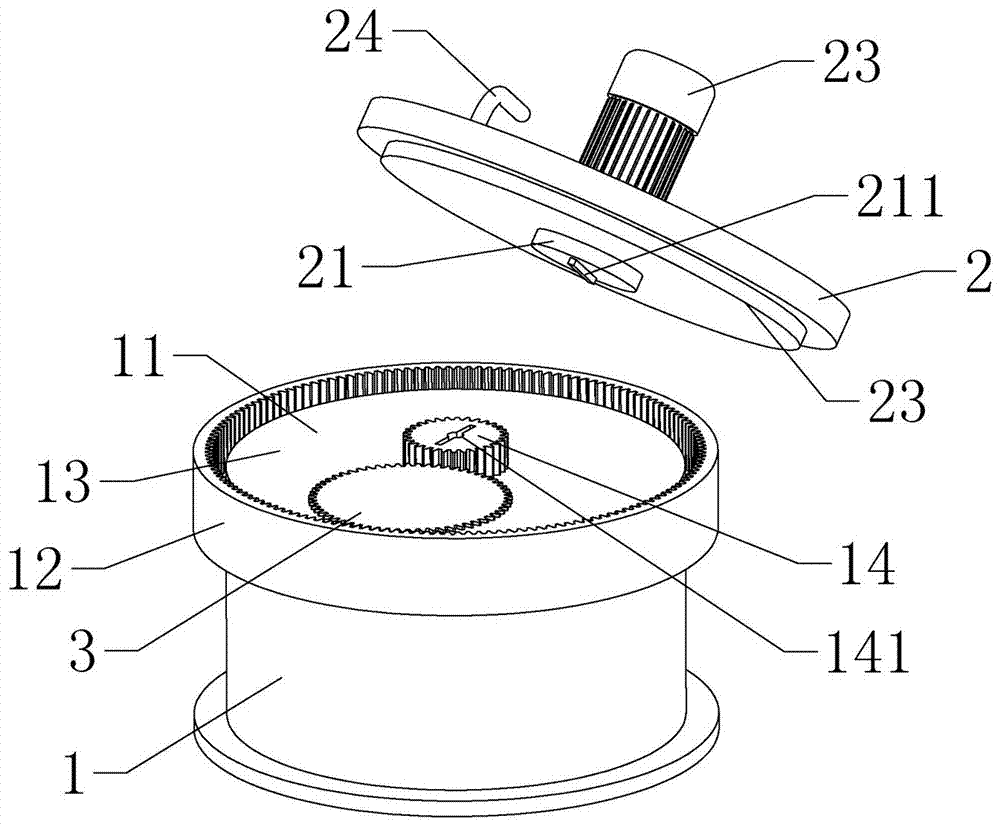

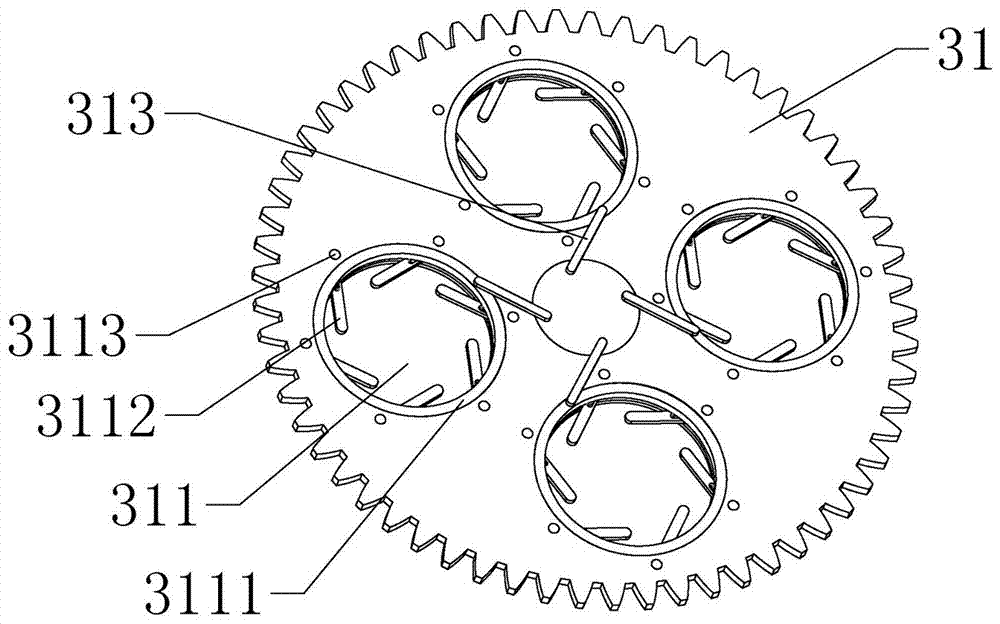

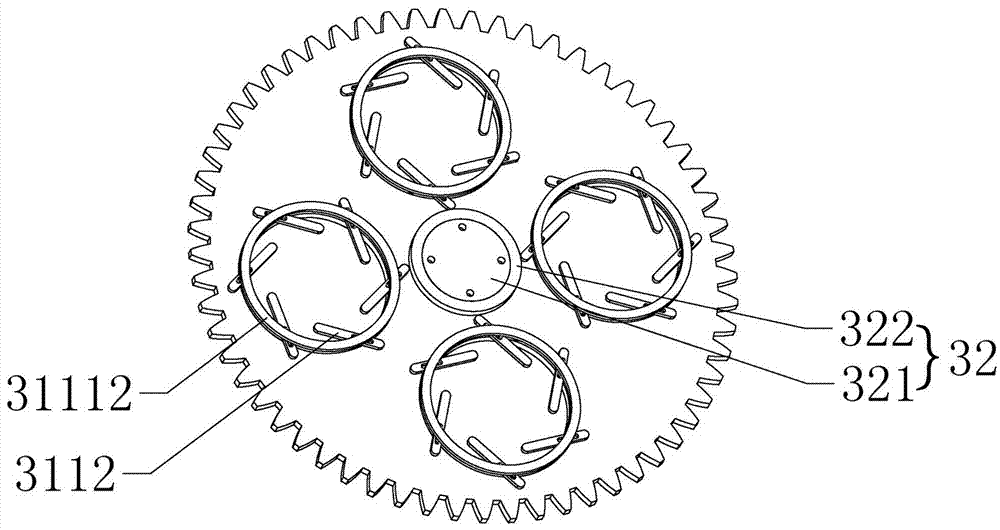

[0029] according to Figure 1 to Figure 6 As shown, a double-sided grinding machine for cylindrical wafers includes: a base table 1, an upper pressing table 2 and a planetary wheel 3, a grinding chamber 11 is provided on the top of the base table 1, and internal teeth are provided on the outer ring of the grinding chamber 11 Gear 12, the bottom of grinding chamber 11 is provided with bottom grinding sheet 13, and the center of grinding chamber 11 is provided with driving gear 14, and upper pressing table 2 comprises, center driving disc 21, driving motor 22 and upper grinding sheet 23, driving motor 22 and center drive The discs 21 are connected, the central drive disc 21 is assembled with the drive gear 14, the upstream star wheel 3 in the plane direction is arranged between the drive gear 14 and the internal gear 12, and the upstream star wheel 3 in the height direction is arranged on the upper grinding plate 23 and the bottom grinding plate between 13; the planetary wheel 3...

Embodiment 2

[0035] The difference from the above-mentioned embodiment 1 is that, according to Figure 8 As shown, the end of the diameter adjusting rod 3112 away from the hinged fixed end 31121 is provided with a movable chuck 31123, the movable chuck 31123 is hingedly connected with the diameter adjusting rod 3112, and the movable chuck 31123 is C-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com