Noncontact reciprocating motion counter

A technology of reciprocating motion and counter, applied in the directions of engine components, engine lubrication, signal processing, etc., can solve problems such as the oil supply at the lubricating point being lower than the design value, the assembly error of the piston rod, the processing error of the connecting rod, etc., to improve the convenience performance, avoid dynamic seal design, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

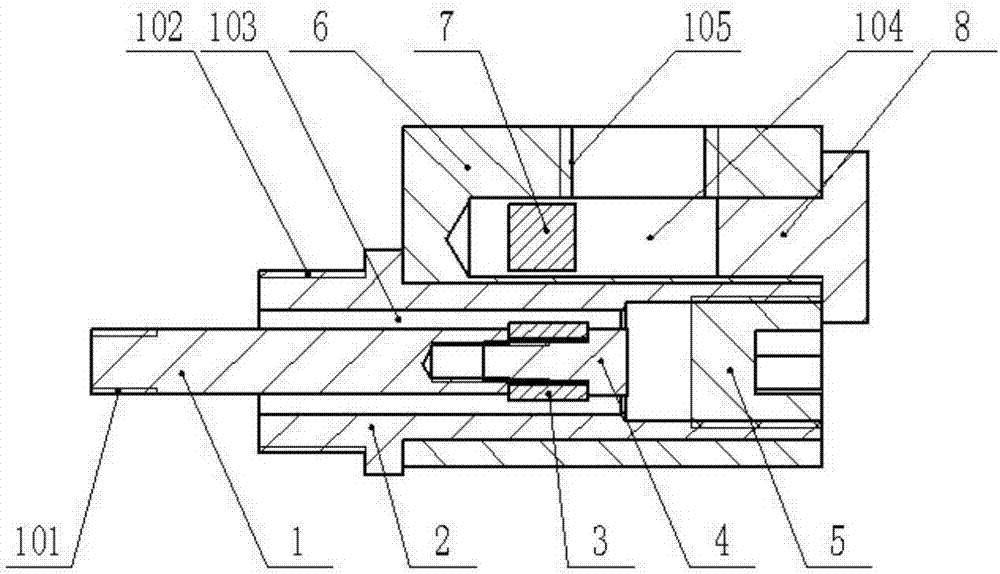

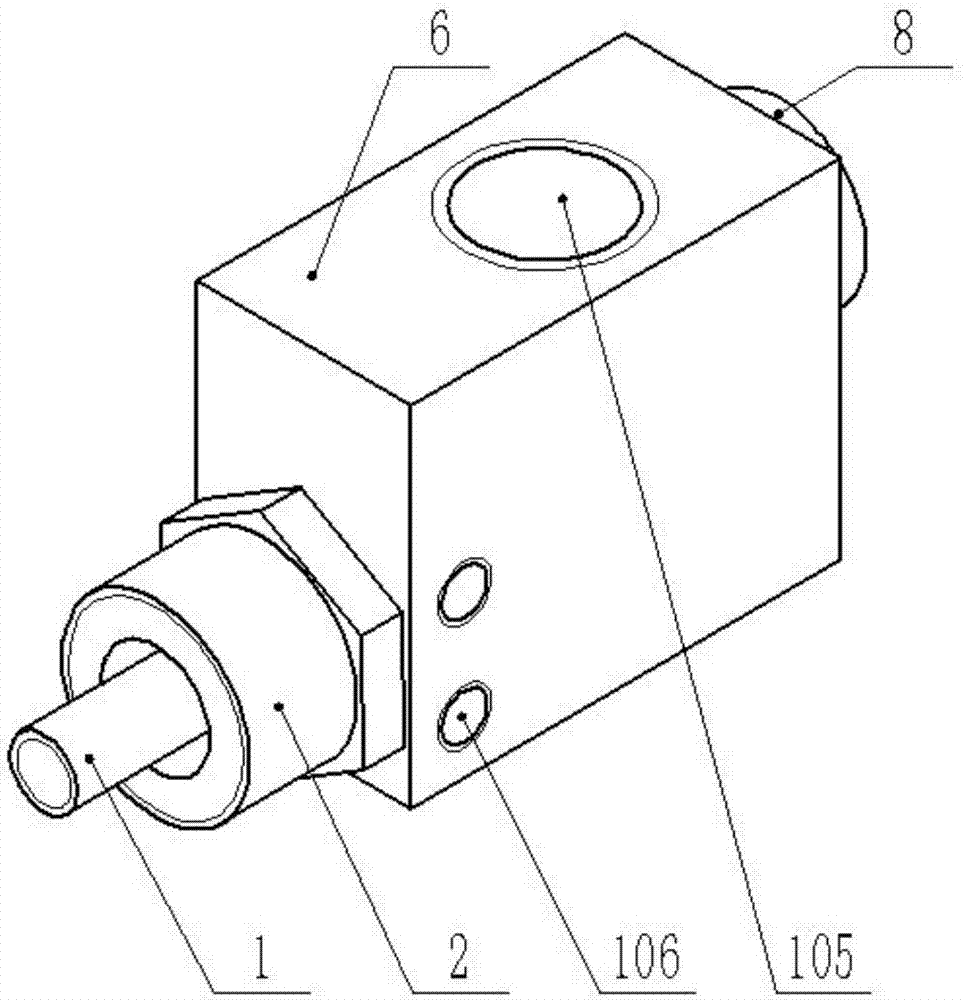

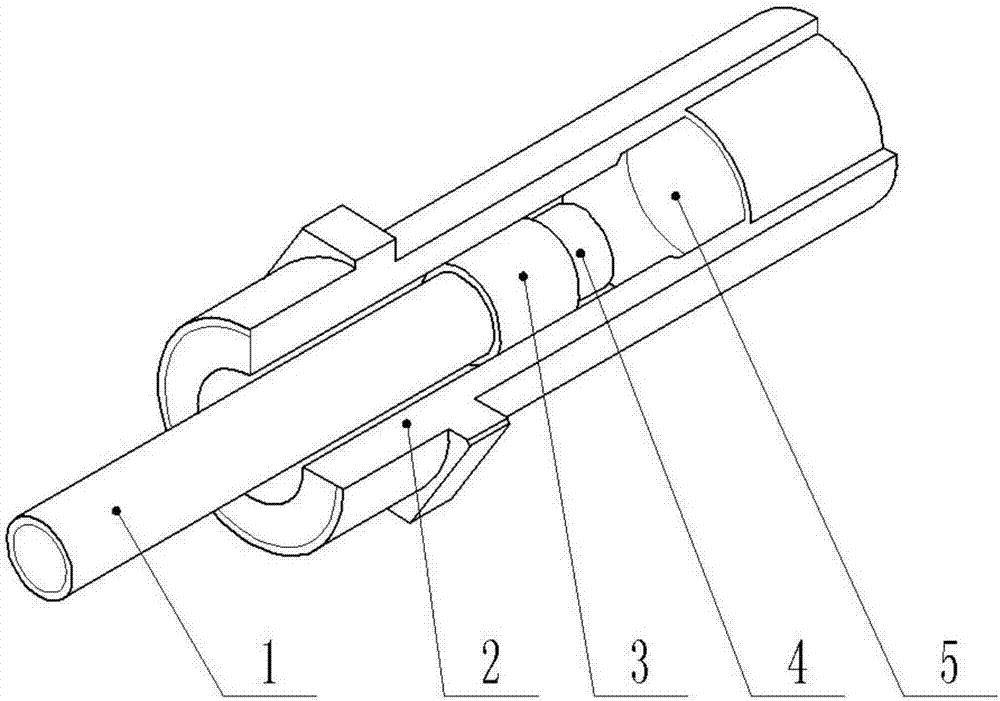

[0017] The main structure of the non-contact reciprocating motion counter described in this embodiment includes a connecting rod 1, a connecting sleeve 2, a ring magnet 3, a bolt 4, a plug 5, a housing 6, a cylindrical magnet 7, a rubber plug 8, a connecting rod outer Thread 101, connecting sleeve external thread 102, connecting sleeve cavity 103, housing inner hole 104, proximity sensor mounting hole 105, housing fixing thread 106; the left end of the cylindrical connecting rod 1 and the piston rod in the progressive distributor Connection, the right end of the connecting rod 1 is covered with a ring magnet 3, close to the right side of the ring magnet 3 is provided with a bolt 4 to support and prevent the ring magnet 3 from slipping off the connecting rod 1, the ring magnet 3 can be used with the progressive oil volume The piston rod in the distributor reciprocates, and through the attraction of the ring magnet 3 and the cylindrical magnet 7, the reciprocating motion of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com