Light-condensing reflector and bean-container lamp comprising same

A technology of reflectors and bean gall lamps, which is applied in the direction of reflectors, semiconductor devices of light-emitting elements, light sources, etc., and can solve problems such as power limitations of LED light sources and increased weight of bean gall lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0039] Structural description of the first embodiment of the concentrating reflector described

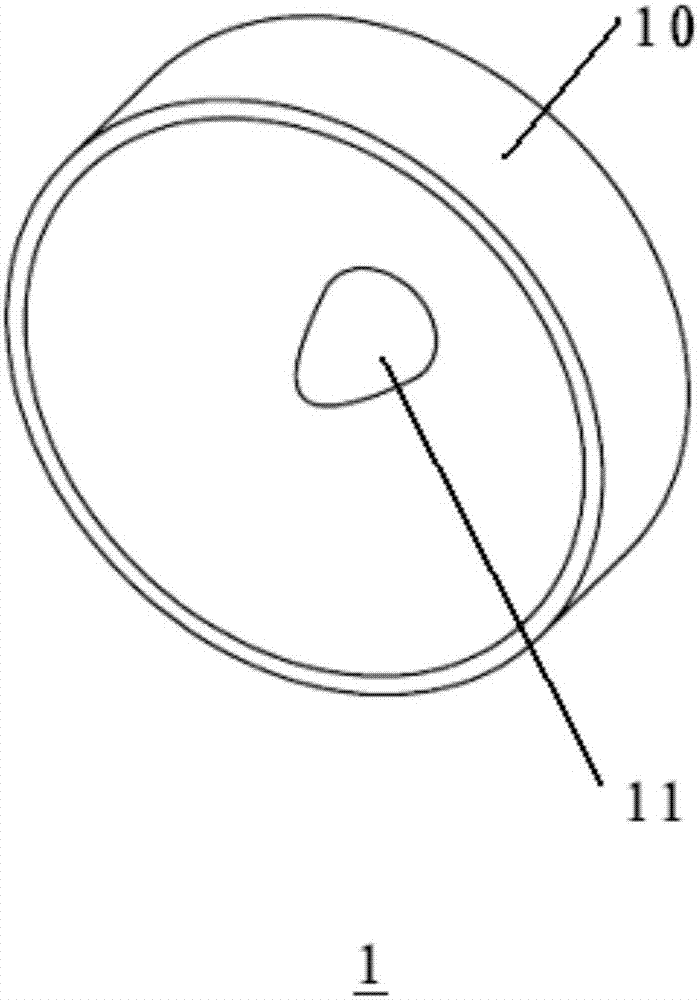

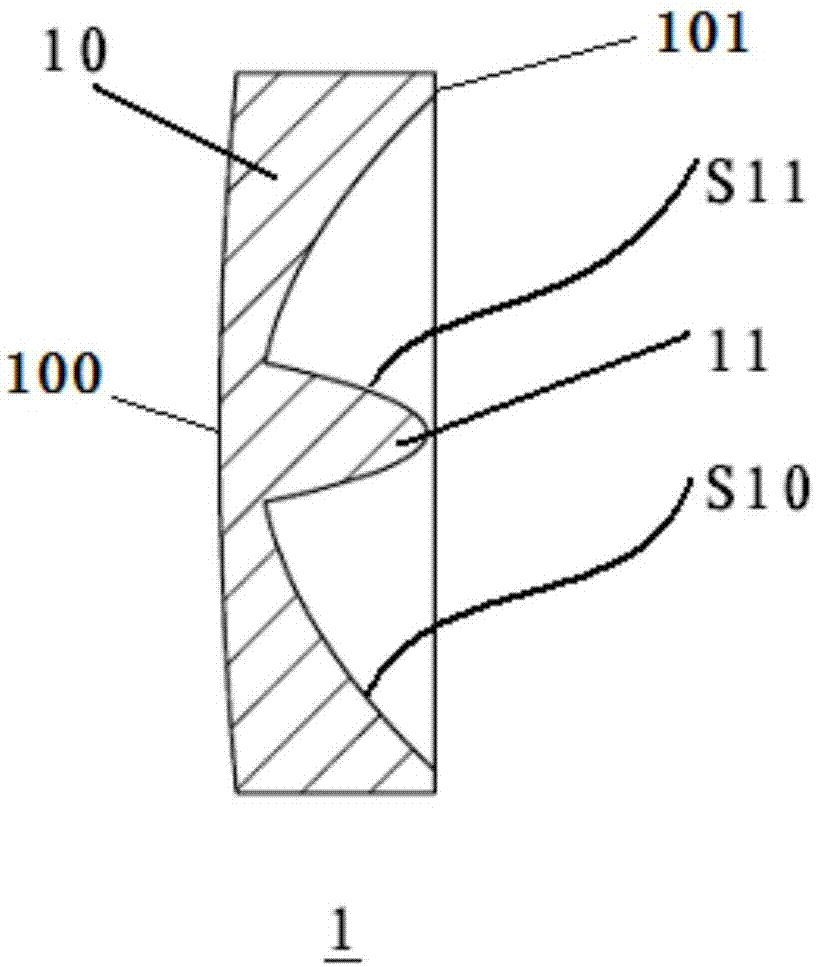

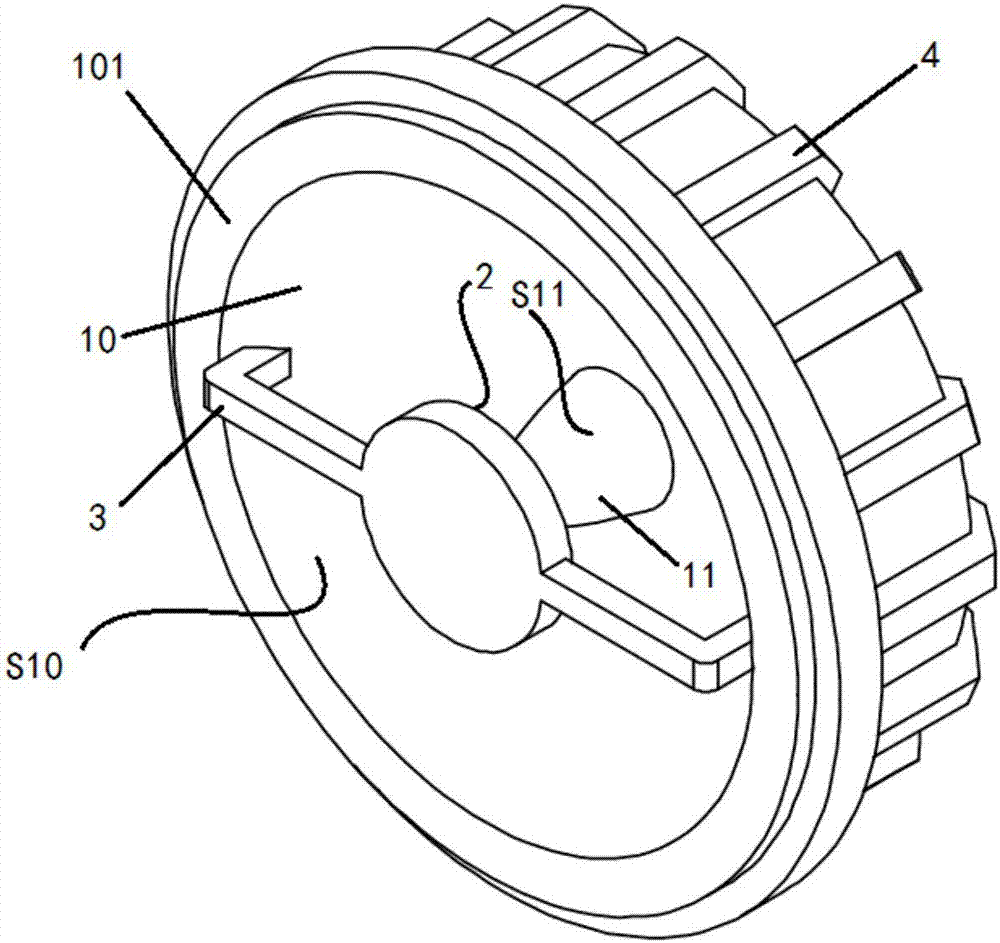

[0040] Such as Figure 1-2 As shown, the LED light-concentrating reflector 1 includes a reflective bowl 10 and a reflective beam splitter 11, and the reflective bowl and reflective beam splitter can be formed of metal materials, such as aluminum alloy. Alternatively, it can be formed by using materials suitable for injection molding such as PS and ABS. In any case, the reflective surfaces of the reflective bowl 10 and the reflective beam splitter 11 can be covered with a metal coating to improve reflection efficiency, such as aluminum metal coating.

[0041] The reflective bowl 10 includes a bottom central portion 100, a reflective bowl edge 101 defining a bowl mouth plane, and a concave (or may be called hollow) bowl extending between the bottom central portion 100 and the reflective bowl edge 101 The reflective surface S10 is a first specular reflective surface S10 formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com