Preprocessing method for optical proximity correction technology

An optical proximity correction and preprocessing technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as variation and inability to remove graphic protrusions, so as to eliminate influence and improve accuracy and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

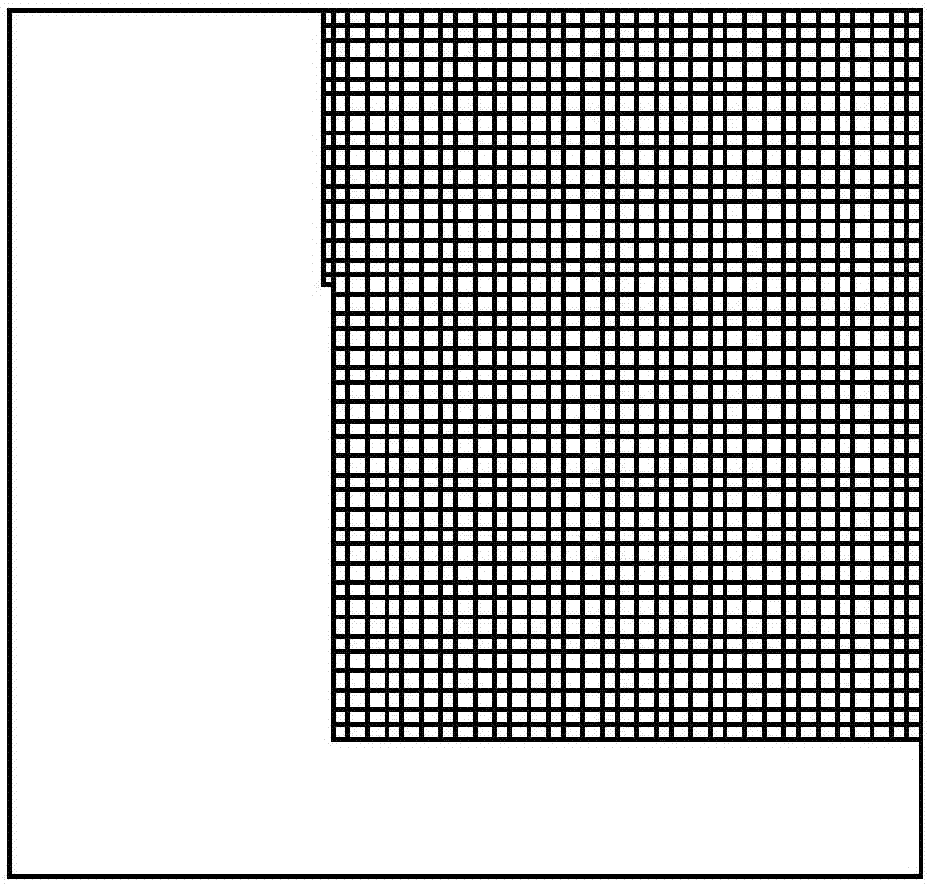

[0047] Such as Figure 6 As shown, there is a graphic side bulge 2 on graphic 1, and graphic 1 has multiple graphic sides, one of which is at a 45° angle to the X axis, and graphic side bulge 2 is located on the 45° hypotenuse, and the graphic side is raised 2 is parallel to the X-axis, and the figure side protrusion 2 is less than 5nm, and the two figure sides adjacent to the figure side protrusion 2 are respectively the first figure side 3 and the second figure side 4 (the figure side protrusion 2 will be 45° The hypotenuse is divided into the first graphic edge 3 and the second graphic edge 4), the relative angle of the first graphic edge 3 and the graphic edge protrusion 2 at the inside of the graphic 1 is 225 °, the second graphic edge 4 and the graphic edge protrusion 2. The angle between the sex pairs inside the graph 1 is 135°, and all the graph edges and the graph edge protrusions 2 are located on the graph grid points based on the minimum precision grid;

[0048] Su...

Embodiment 2

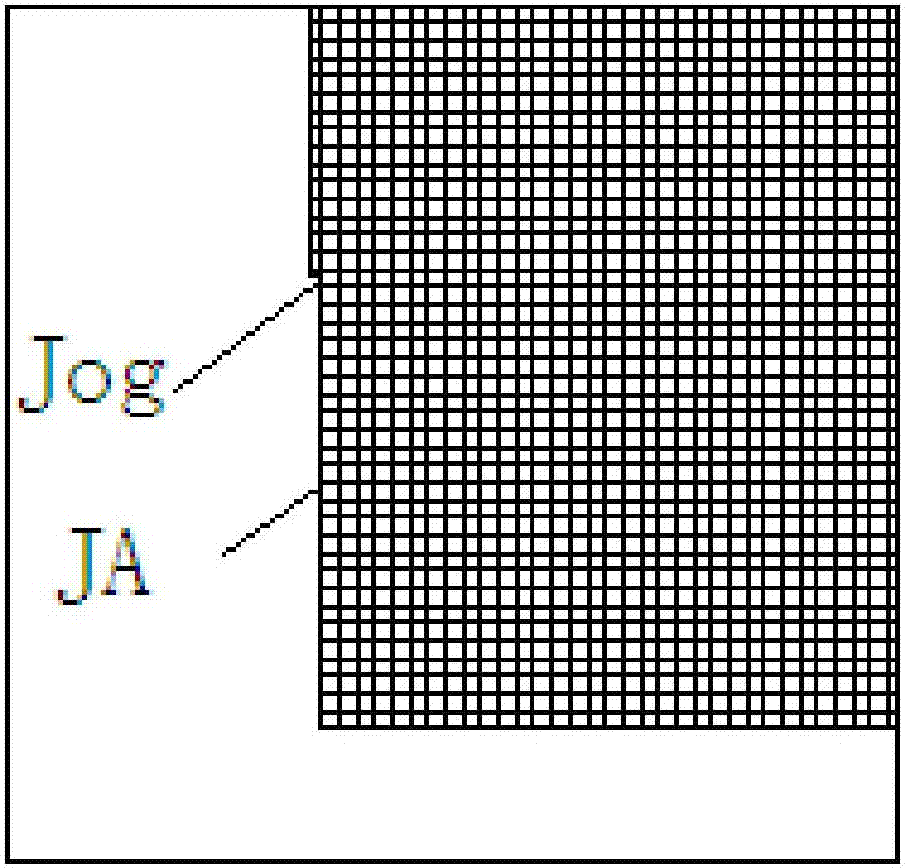

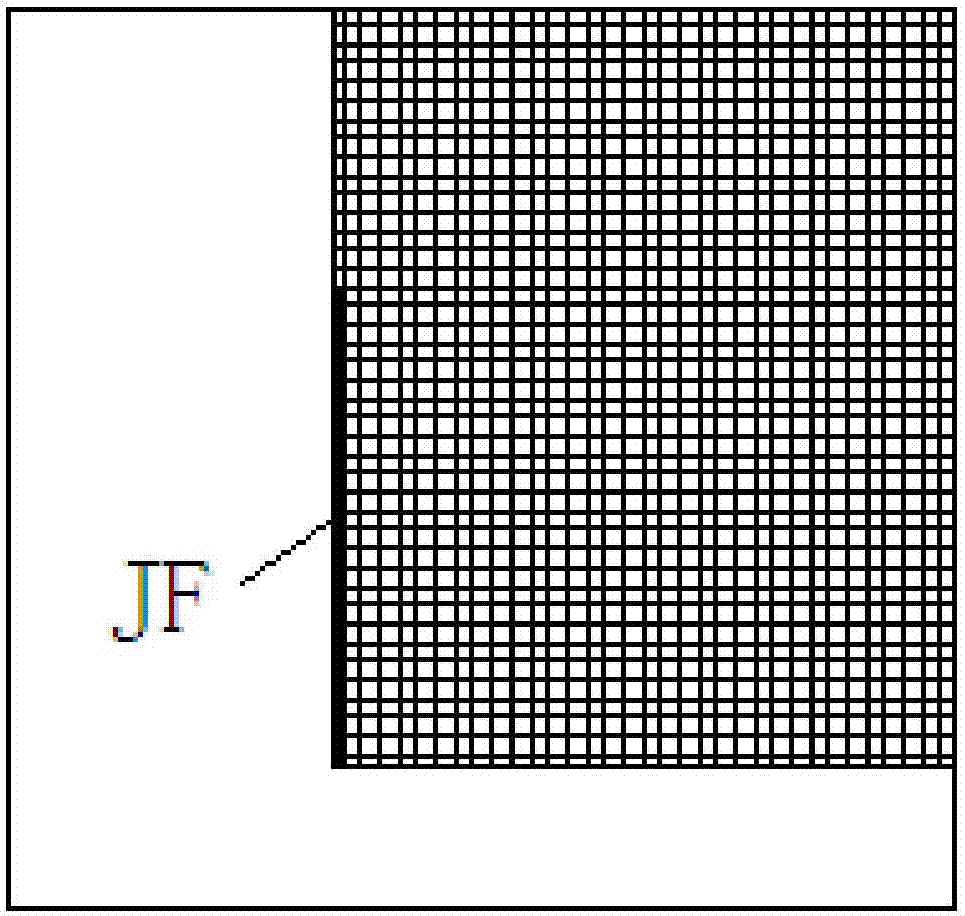

[0055] Such as Figure 15 As shown, there are two figure side protrusions 2 on figure 1 (both the short sides EJA1 and EJA2 are figure side protrusions 2), figure 1 has multiple figure sides, one of the figure sides is 45° to the X axis, and the figure side The bulge 2 is located on the 45° hypotenuse, the short side EJA1 is parallel to the X axis, and the short side EJA2 is perpendicular to the X axis. Before preprocessing, first determine the maximum length of the graphic side bulge 2, assuming that the graphic side bulge 2 The maximum length of the 45° hypotenuse is 2nm, and the maximum length of the 45° hypotenuse is 300nm. When there are two graphic sides protruding 2 on the 45° hypotenuse, then as Figure 15 shown.

[0056] Continue to refer to Figure 15 , first use the DRC tool to select all short sides EJA1 and EJA2 with a length less than 2nm in the graph PTA0, and these short sides form an angle of 0 degrees or 90 degrees with the coordinate axis;

[0057] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com