Shale oil and gas integration output analysis method based on dynamic leakage flow volume

A technology of shale oil and gas analysis methods, applied in the directions of instruments, data processing applications, resources, etc., can solve the problems of reaching the steady-state flow stage, difficult challenges of shale oil and gas, and difficulties in shale oil and gas development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with embodiment the present invention is further described.

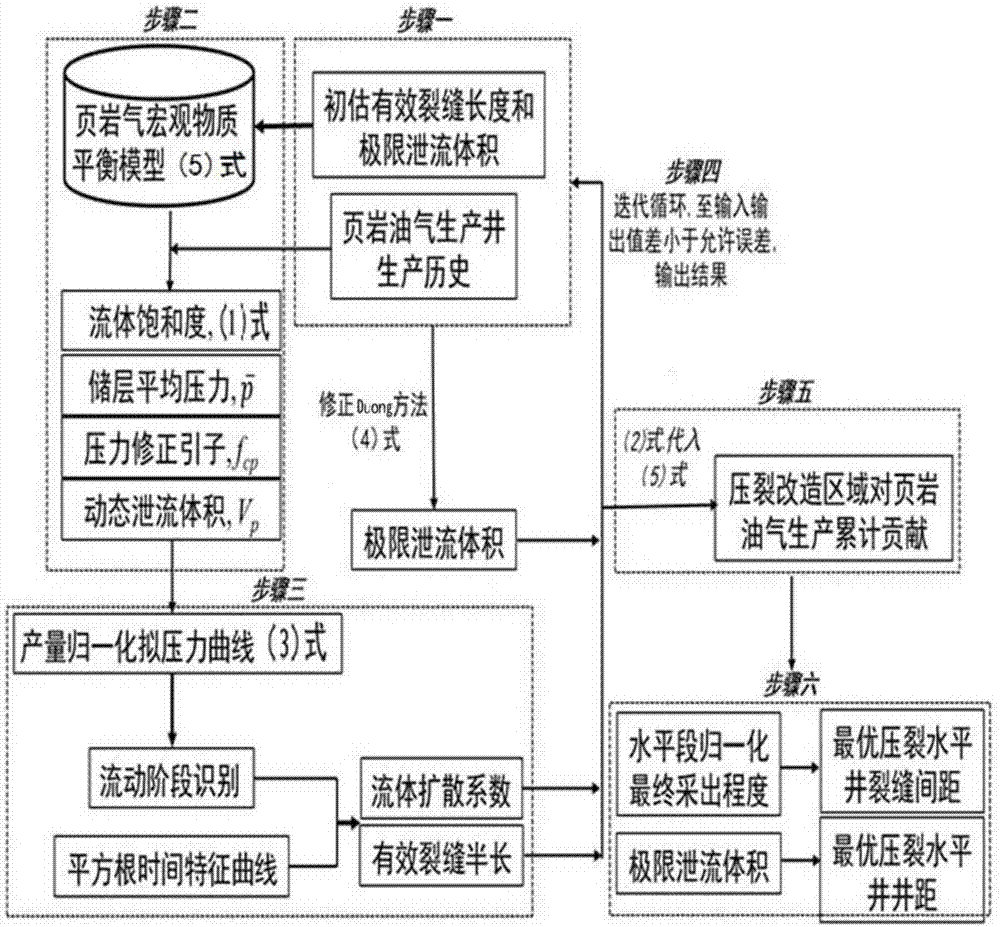

[0057] A method for analyzing comprehensive production of shale oil and gas based on dynamic drainage volume, comprising the following steps:

[0058] (1): Data collation and preparation; required data include: shale reservoir petrophysical properties, fluid physical properties, well parameters and production history of target wells;

[0059] The petrophysical properties of the shale reservoir include compressibility, shale permeability, and oil and gas desorption parameters, the fluid physical properties include viscosity, volume coefficient, and fluid compressibility coefficient, and the well parameters include drilling and fracturing completion parameters. The production history of the target wells mentioned above includes the daily production and cumulative production of oil, gas and water.

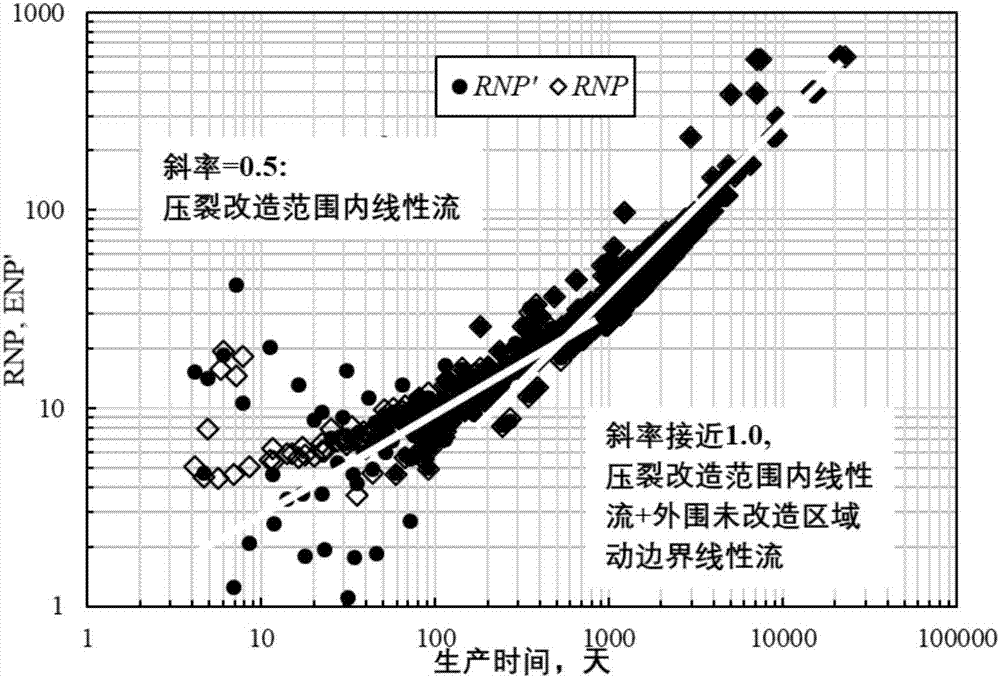

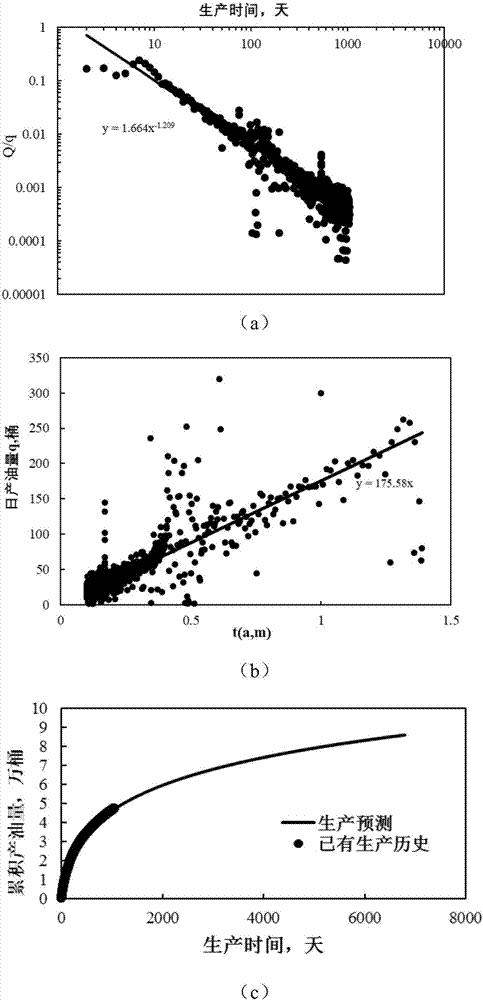

[0060] Taking a sample reservoir of Niobrara shale oil in the United States as an example, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com