Air thermochemical oil gas in-situ hydrogen production and modification simulation system

A technology for in-situ hydrogen production and simulation systems, applied in scientific instruments, instruments, measuring devices, etc., can solve problems such as lack, change detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

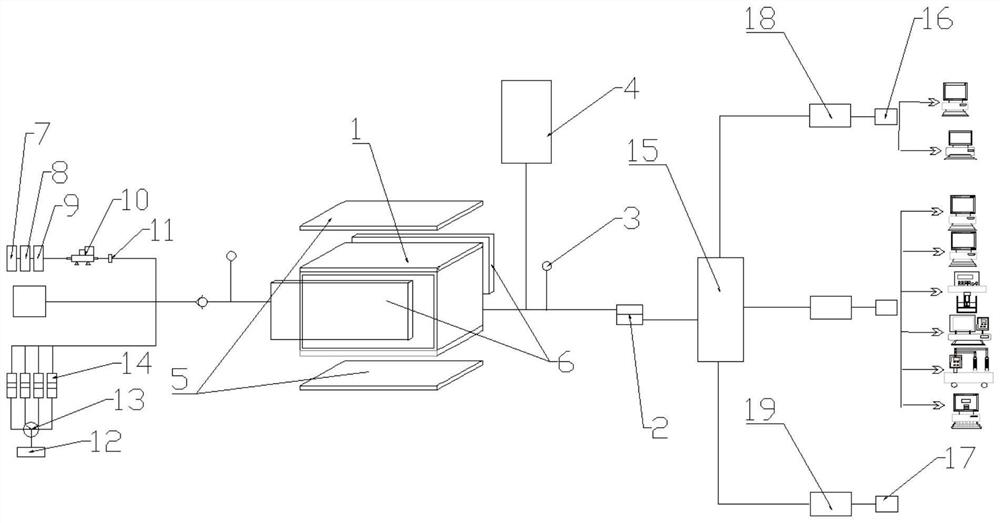

[0022] Please refer to figure 1 , an air thermochemical oil and gas in-situ hydrogen production and upgrading simulation system, including an oxygen supply module, a raw material injection module, a reactor module, an oil-gas-water separation sampling module, a sample analysis module, a gas trace automatic monitoring module, and an intelligent monitoring system module. . The oxygen supply module and the raw material injection module are respectively connected with the inlet of the reactor module for supplying oxygen-enriched gas and reaction raw materials to the reactor module; the outlet of the reactor module is connected with the oil-gas-water separation sampling module for separating the reaction products; The sample analysis module analyzes the samples collected in the oil-gas-water separation sampling module.

[0023] The reactor module includes a reactor 1, the outlet of the reactor 1 is provided with a back pressure valve 2, which is used to control the pressure in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com