One-step step-by-step assembly motor rotor automatic press-fitting machine

A technology of motor rotor and press-fitting machine, which is applied in the manufacture of stator/rotor body and other directions to achieve the effects of small runout, high clamping accuracy and high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

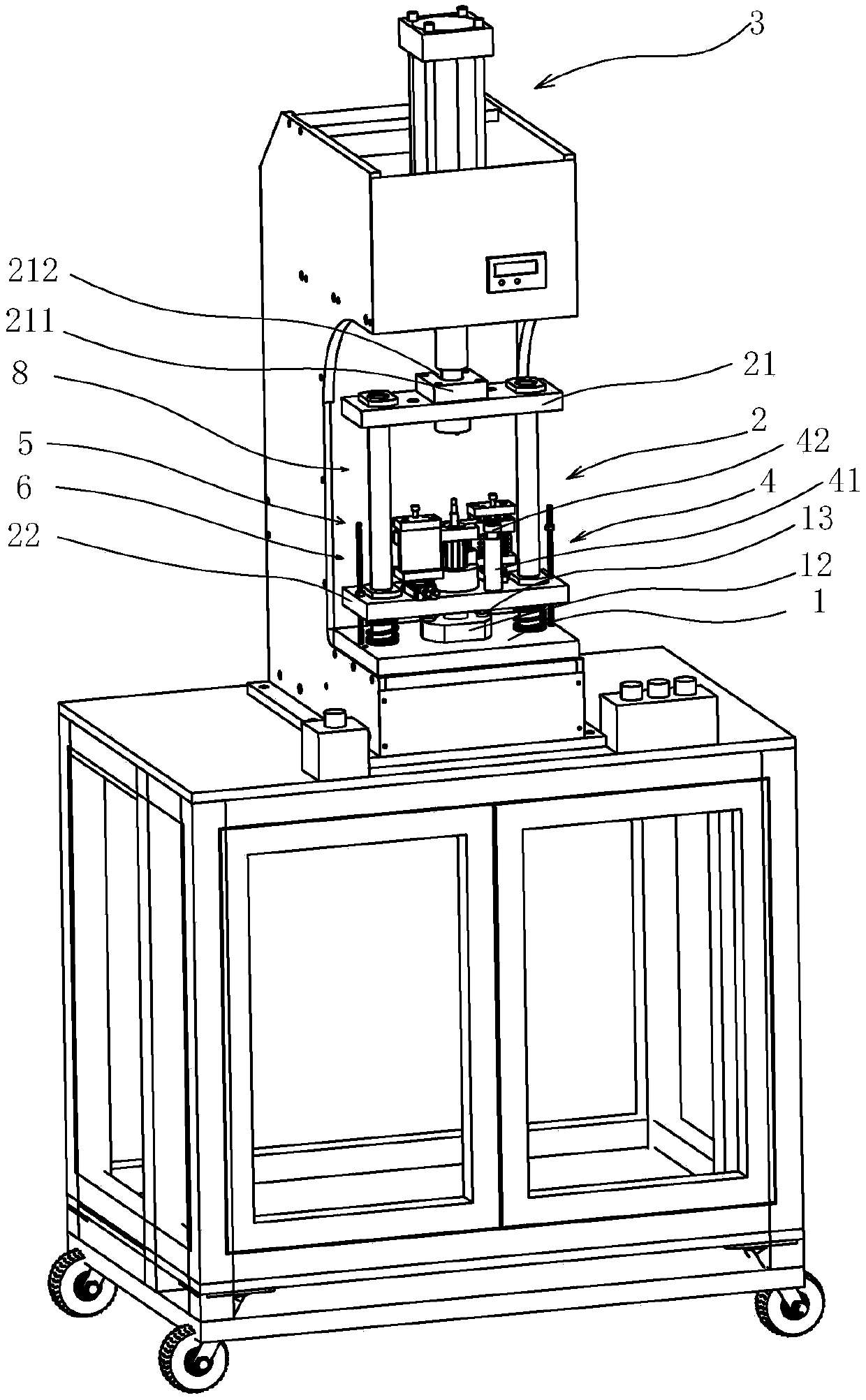

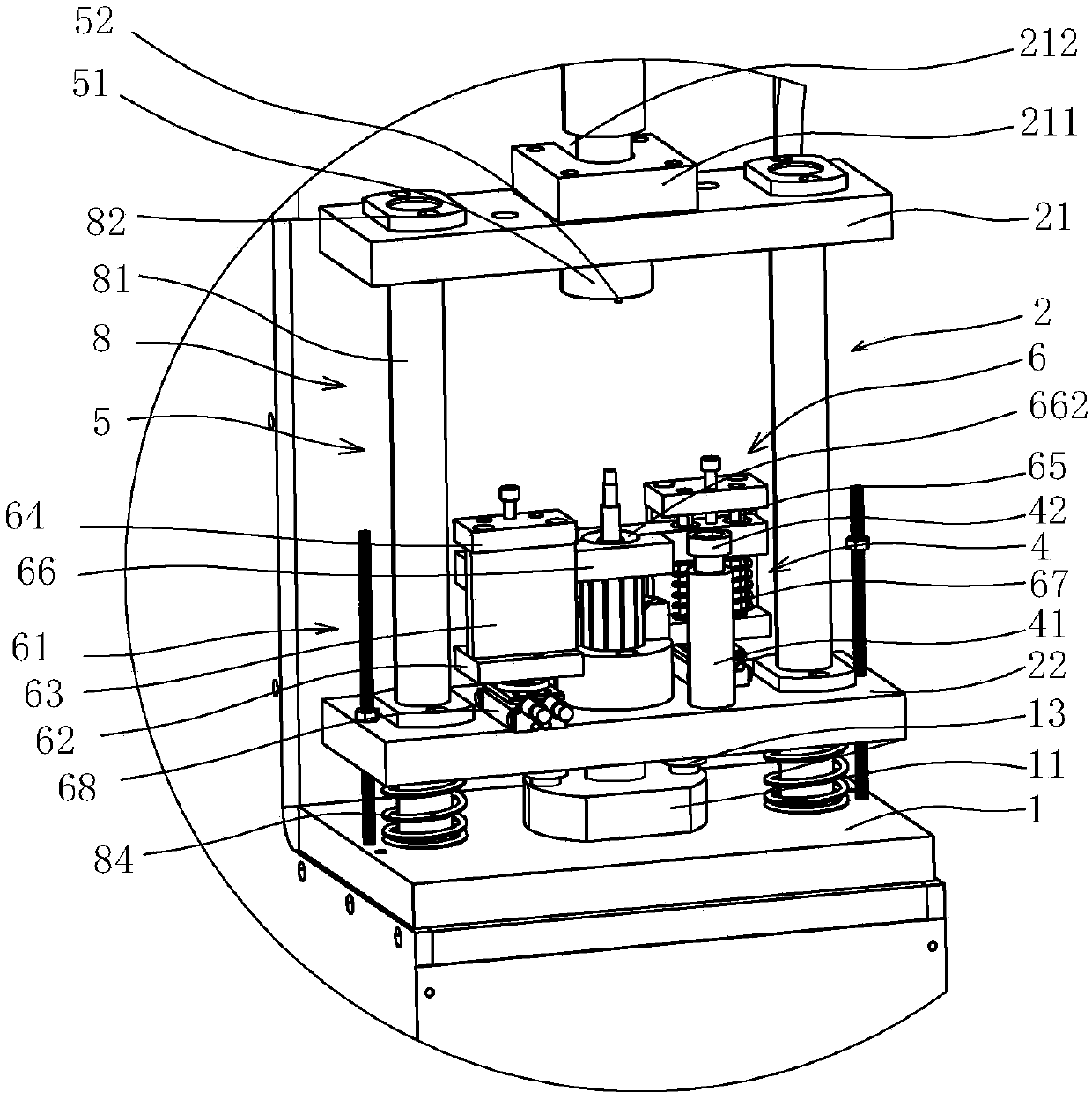

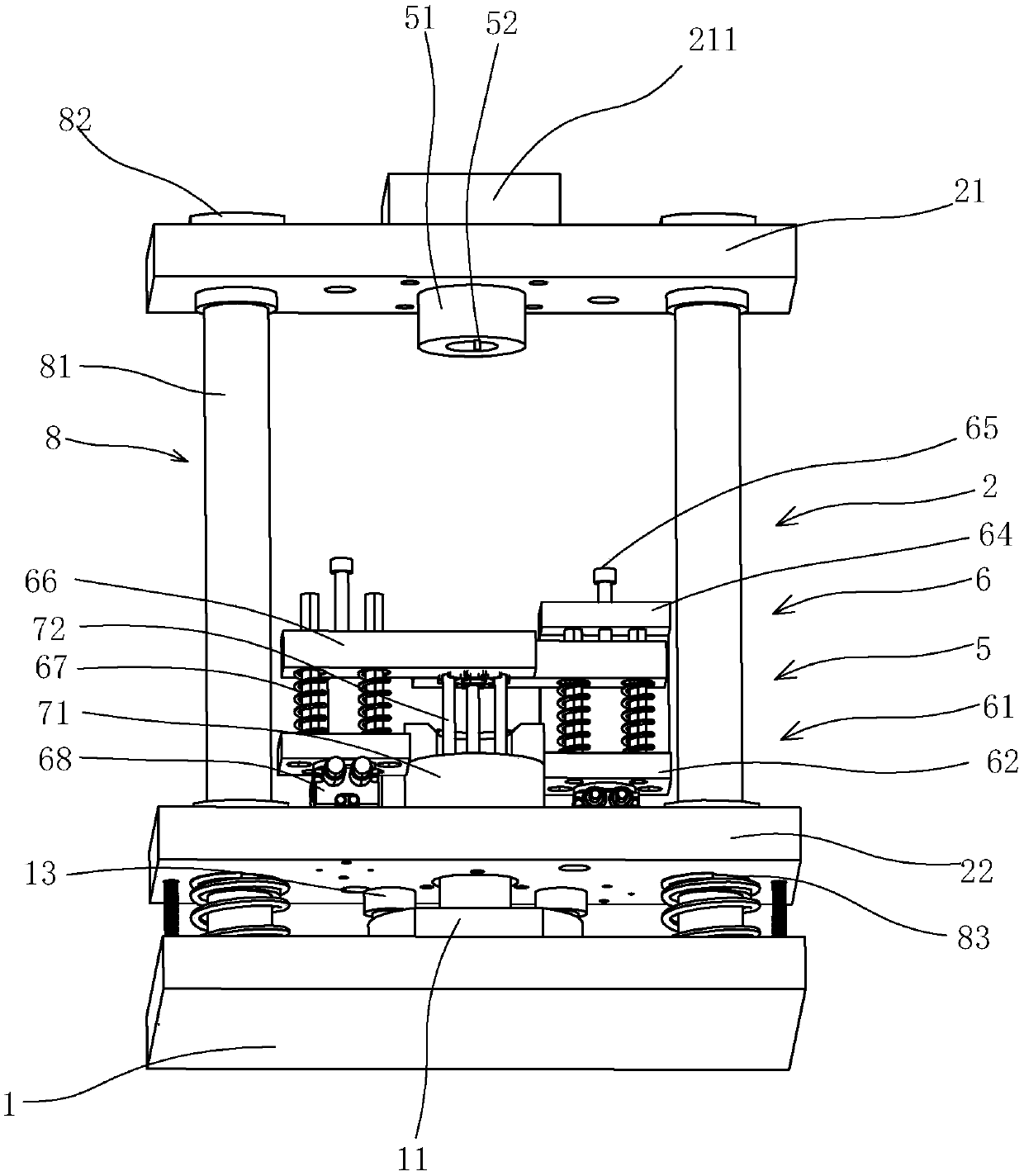

[0029] Such as figure 1 As shown, a one-step graded assembly motor rotor automatic press-fitting machine is provided with a base 1, and a graded longitudinal feed mechanism 2 is arranged on the base 1, and the graded longitudinal feed mechanism 2 includes a first press plate 21 and a second press plate 22. The first pressing plate 21 is provided with a longitudinal drive mechanism 3, the clutch device 4 is arranged between the first pressing plate 21 and the second pressing plate 22, and the first pressing plate 21 and the second pressing plate 22 A segmented coaxial positioning fixture 5 is also provided between them. The clutch device 4 includes a clutch lever 41 fixedly installed on the second pressure plate 22 , and the clutch lever 41 is provided with a height-adjusting bolt 42 .

[0030] The first pressure plate 21 is provided with a vertical guide mechanism 8. The vertical guide mechanism 8 includes a guide rod 81 symmetrically arranged on the base 1, and a lubricating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com