Straw shredding and deep-burying and returning machine for improving soil plough layer structure

A technology for crushing straw and improving soil, which is applied to harvesters, agricultural machinery and tools, and agriculture. It can solve the problems of single stubble cutter and ditching machine, complex straw deep burial process, and high operating conditions, so as to reduce farming resistance. , Reduce production costs and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

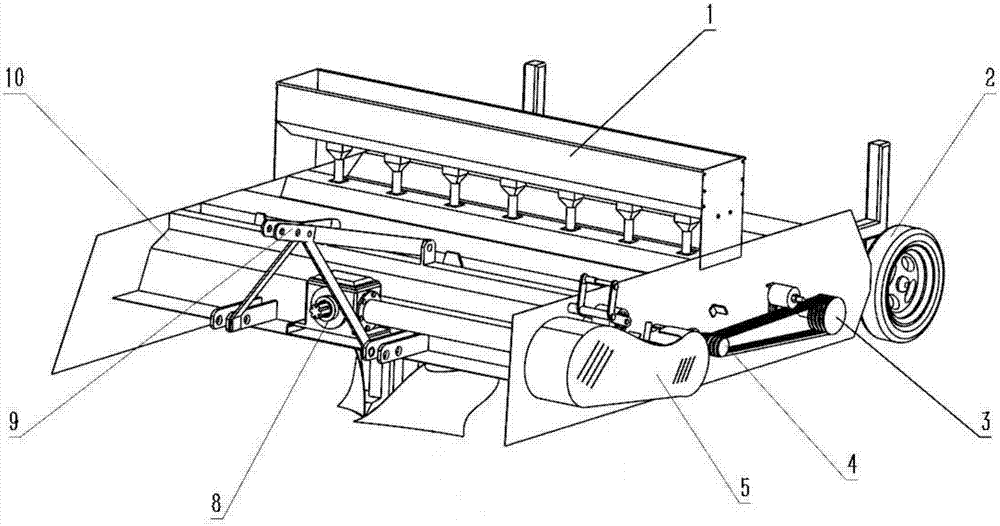

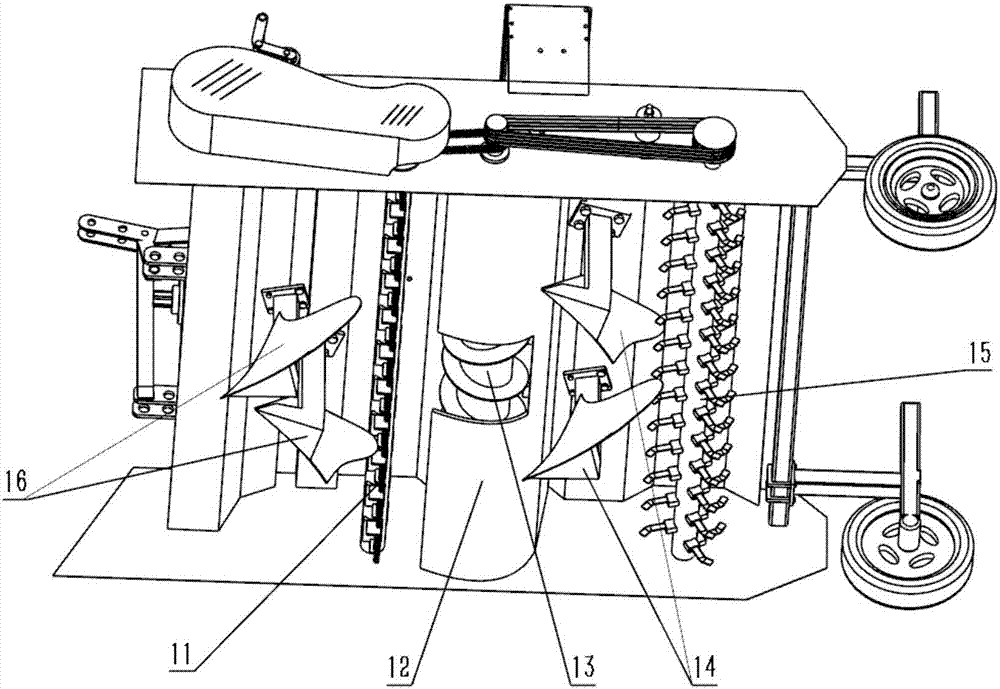

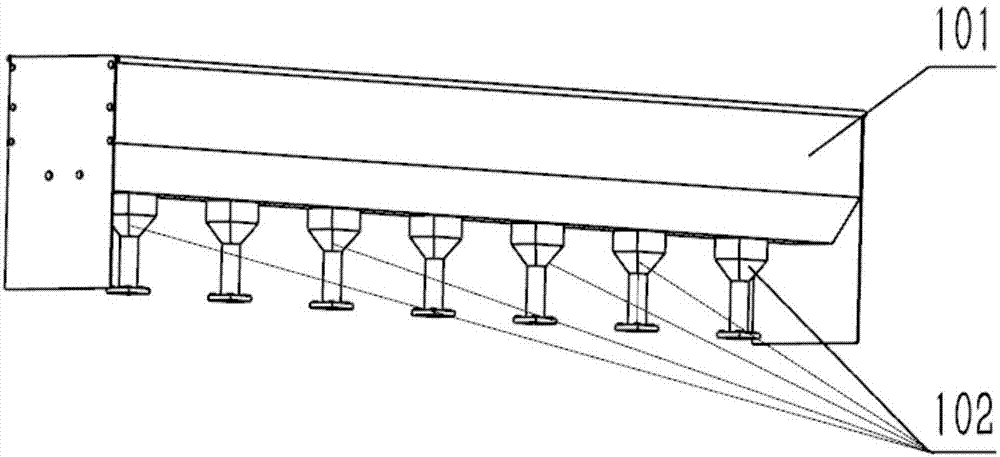

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a straw crushing and deep-burying machine for improving the structure of the soil plow layer, which includes a frame 10, a suspension device 9 is provided above the front end of the frame 10, and a gearbox 8 is provided directly below the suspension device 9 A ditching device 16 is provided under the front end of the frame 10; a fertilization device 1 is provided above the middle part of the frame 10, and a fertilization device 1 is arranged at the bottom of the middle part of the frame 10, and the bottom part of the frame 10 is sequentially connected by a transmission mechanism from front to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com