A high-precision optical instrument base frame welding process

A technology of optical instruments and welding processes, which is applied in the direction of welding equipment, welding media, welding equipment, etc., can solve the problems of difficult welding of high-precision optical instrument base frames, high precision requirements, etc., to ensure product dimensional stability and dimensional accuracy, Optimizing the welding parameters and the effect of small line energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

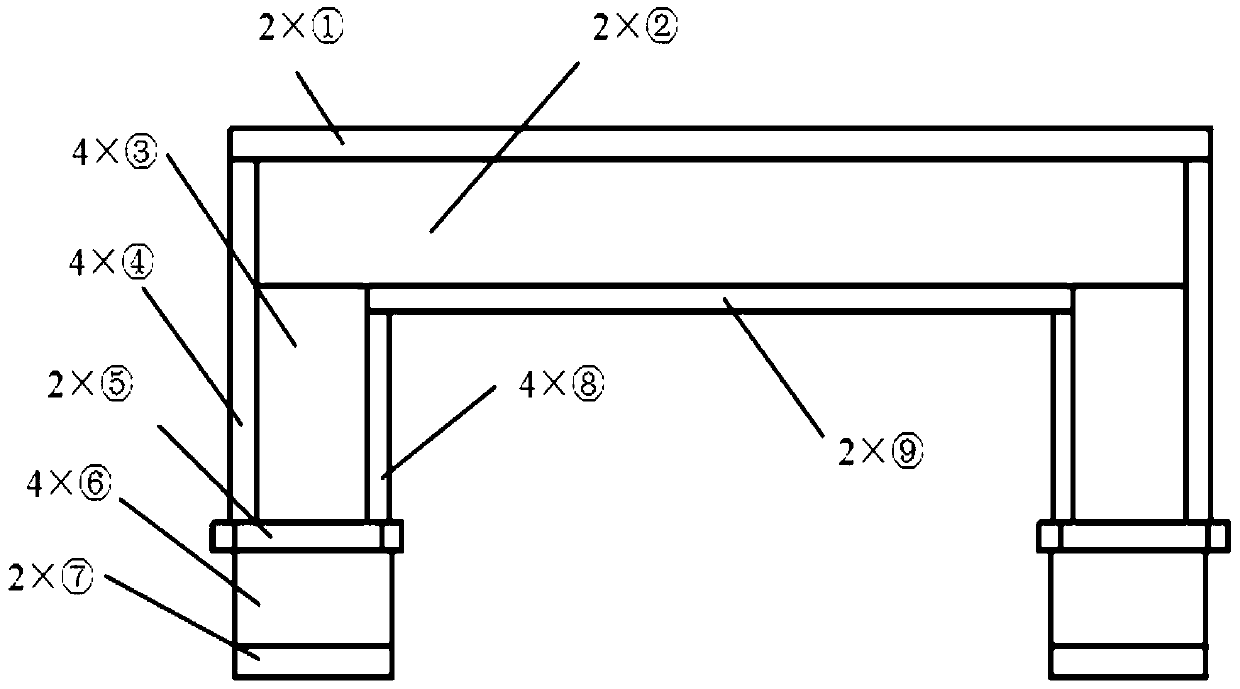

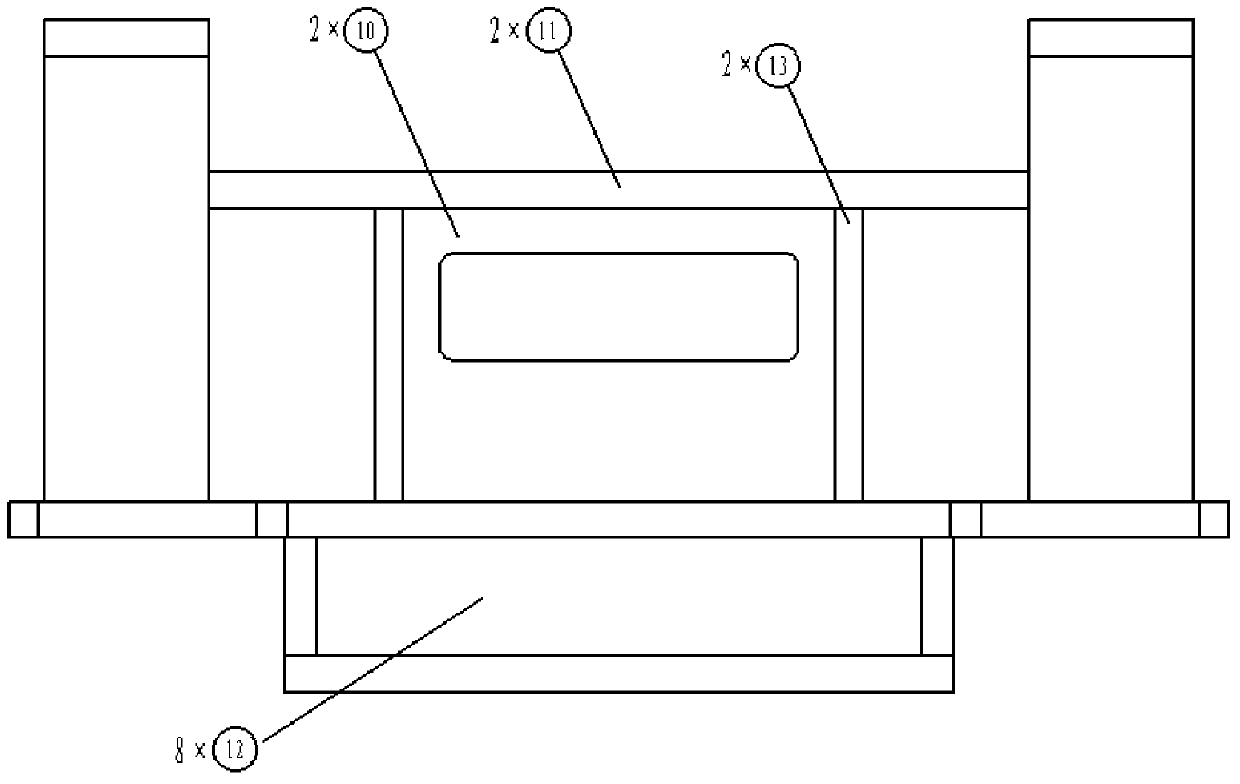

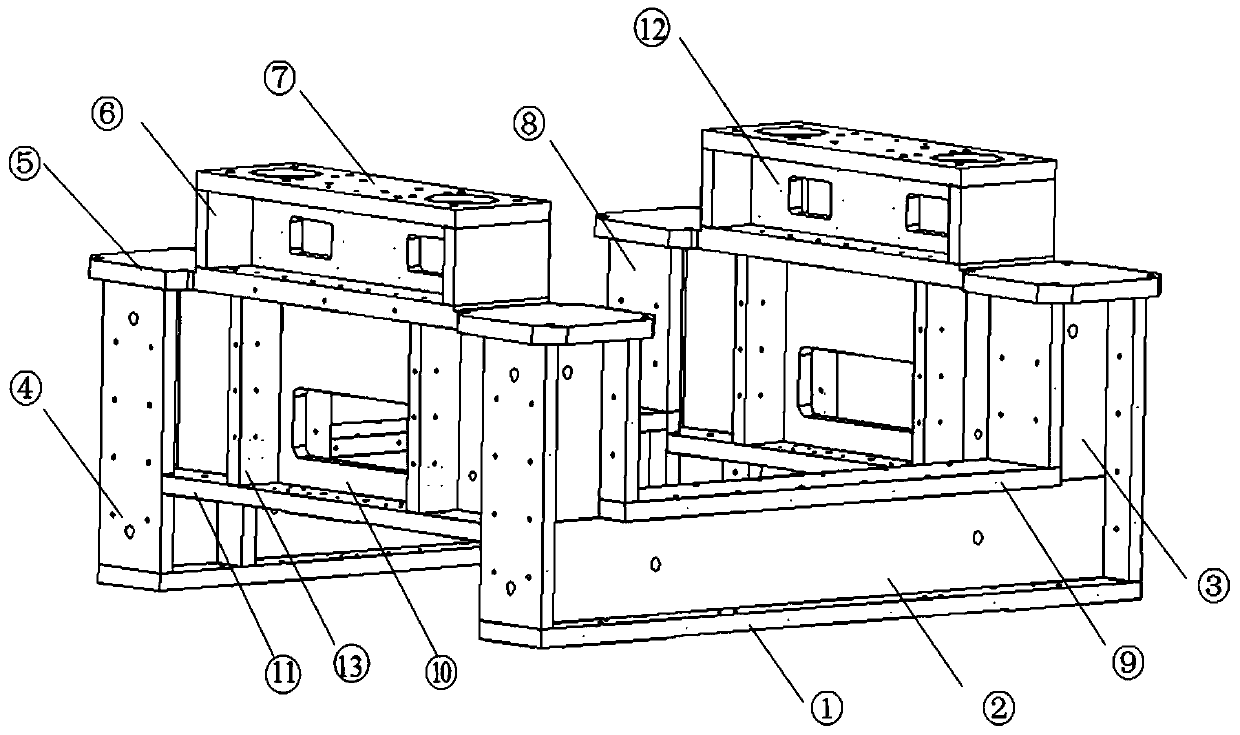

[0024] In the specific implementation process, the application of the welding process of the present invention provides a reference value for the welding of the base frame of high-precision optical instruments in the field of equipment manufacturing. The traditional welding process is used to achieve low-cost and high-efficiency welding of high-precision parts. The principle of butt welding for precision optical instrument frames is proposed, and the heat treatment method and process for removing the welding stress of large thick plate stainless steel are given. Manual arc welding is used to weld the 304 stainless steel base frame. The welding process includes pre-welding treatment, welding process and post-welding heat treatment. The specific process is as follows:

[0025] 1. According to different plate thicknesses and different types of welded joints, choose different grooves and sizes. The grooves include U-shaped grooves, V-shaped grooves, and single V-shaped grooves to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com