Die injection molding forming measurement and control system and method

A technology of injection molding and measurement and control system, which is applied in the measurement and control system and field of measurement and control of injection mold molding process, which can solve the problems of no real-time monitoring of molding parameters inside the cavity, inability to install fluid pressure and temperature measurement and control, and inability to realize large-capacity data comparison, etc. , to achieve the best molding efficiency, convenient and reliable reading, and shorten the molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

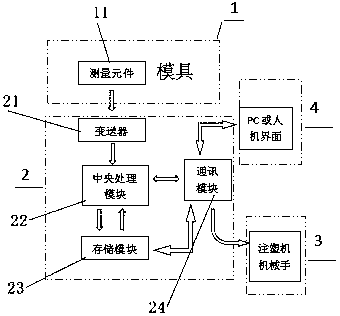

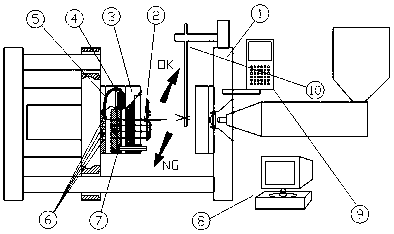

[0036] In this embodiment, a mold injection molding measurement and control system and measurement and control method refer to figure 1 , including the measuring element 11 in the mold, the mold forming measuring and controlling instrument 2 and the upper computer 4. refer to figure 2 , when the injection mold with injection molding measurement and control system to be installed in the injection molding machine After being on, the sensor can be measured by The measured value is output by the mold injection molding measuring and controlling instrument Determine whether it is qualified or not, and control the manipulator at the same time Distinguishing products are placed along different paths, and the judgment is manually operated by personal PCs , connected to the mold injection molding measuring and controlling instrument Personal PC Its standard parameters and judgment interval can be set for the mold injection molding measuring and controlling instrument U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com