Preparation method of fluorescent polarizing film based on directional arrangement of quantum rods

A technology of directional alignment and fluorescence polarization, which is applied in polarizing components, chemical instruments and methods, and printing of special varieties of printed matter, can solve the problems of limited directional effect and large material loss, and achieves easy operation, simple experimental equipment, and extensive The effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this example, the aligned quantum rod thin film is prepared by the following method, which specifically includes the following steps:

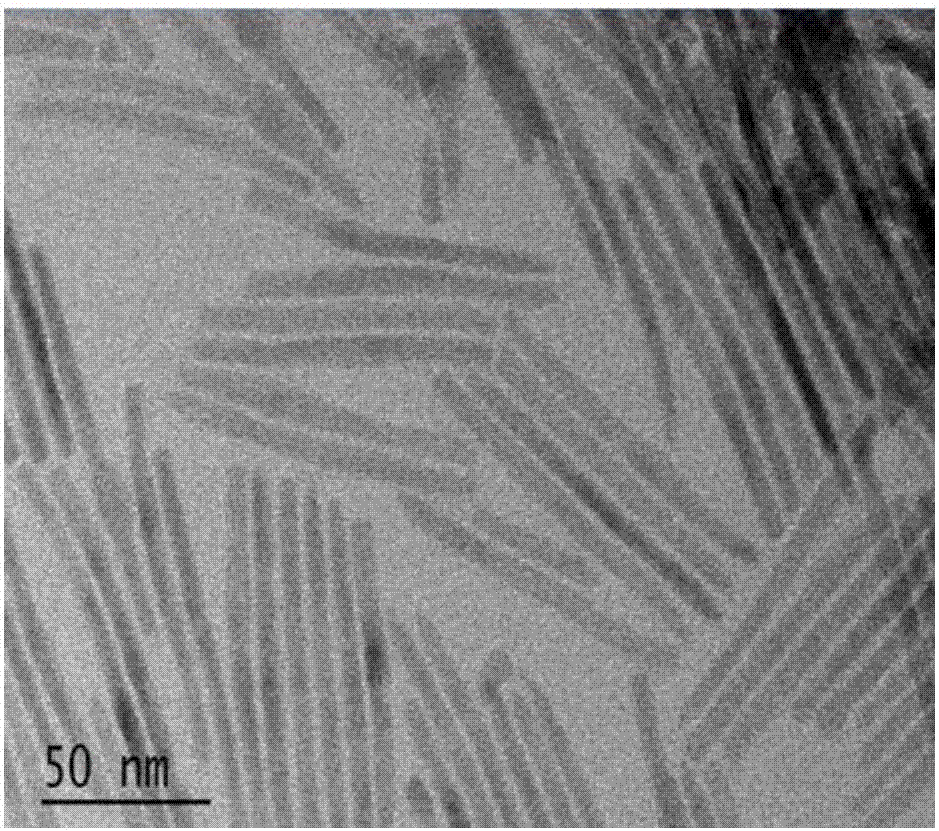

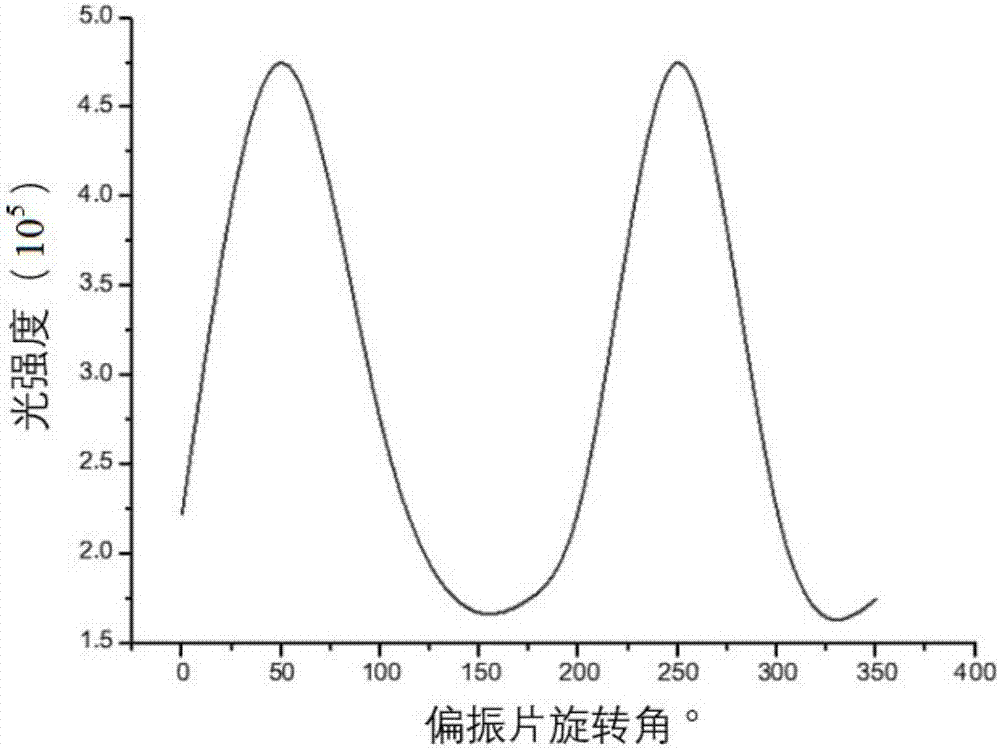

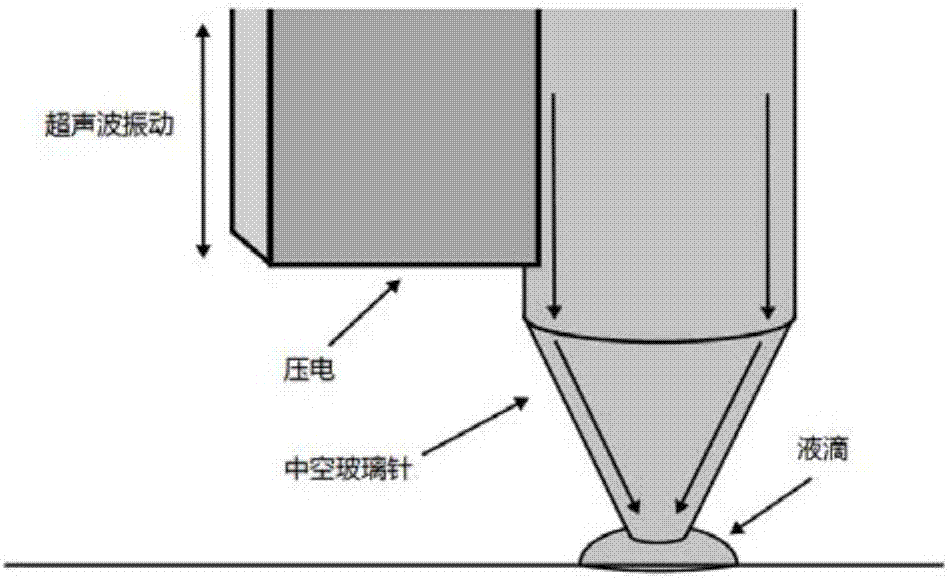

[0067] The quantum rod material CdSe / CdS is prepared into the quantum rod ink by solvent toluene, the concentration of the quantum rod ink is 20mg / mL; the quantum rod ink is injected into the solution plate, and the inkjet printing needle is immersed in the quantum rod ink in the solution plate, The needle will attract the solution into the needle, select the upper left corner of the ordinary glass substrate as the coordinate origin, move the needle to the bottom of the printer by moving the printer’s mechanical arm, lower the needle until it touches the surface of the printing substrate, import and print the preset graphics, follow the preset Set the graph to print ( image 3 It is an enlarged schematic diagram of the structure of the needle head part of the printer used in the present invention), when printing is carried out, such ...

Embodiment 2

[0073] In this example, the aligned quantum rod thin film is prepared by the following method, which specifically includes the following steps:

[0074] The red quantum rod material is prepared into quantum rod ink with a mixed solvent of toluene and o-dichlorobenzene, the concentration of quantum rod ink is 40mg / mL; the quantum rod ink is injected into the solution plate, and the inkjet printing needle is immersed in the solution plate. In the quantum rod ink, the needle will attract the solution into the needle, select the upper left corner of the ITO conductive glass substrate as the coordinate origin, move the needle to the bottom of the printer by moving the printer’s mechanical arm, lower the needle until it touches the surface of the printing substrate, and start printing Preset graphics, print according to the preset graphics ( image 3 It is an enlarged schematic diagram of the structure of the needle head part of the printer used in the present invention), when print...

Embodiment 3

[0077] In this example, the aligned quantum rod thin film is prepared by the following method, which specifically includes the following steps:

[0078] The blue quantum rod material is prepared into quantum rod ink with toluene, and the concentration of quantum rod ink is 10mg / mL; the quantum rod ink is injected into the solution plate, and the inkjet printing needle is immersed in the quantum rod ink in the solution plate, and the needle will The solution is sucked into the needle, select the upper left corner of the PET substrate as the coordinate origin, move the needle to the bottom of the printer by moving the printer arm, lower the needle until the needle touches the surface of the printing substrate, import and print the preset graphics, and proceed according to the preset graphics Print( image 3 It is an enlarged schematic diagram of the structure of the needle head part of the printer used in the present invention), when printing is carried out, such as Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com