Vacuum film coating machine

A vacuum coating machine and vacuum chamber technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of unbalanced coating and incomplete coating, so as to avoid incomplete coating and improve efficiency , to ensure the effect of the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

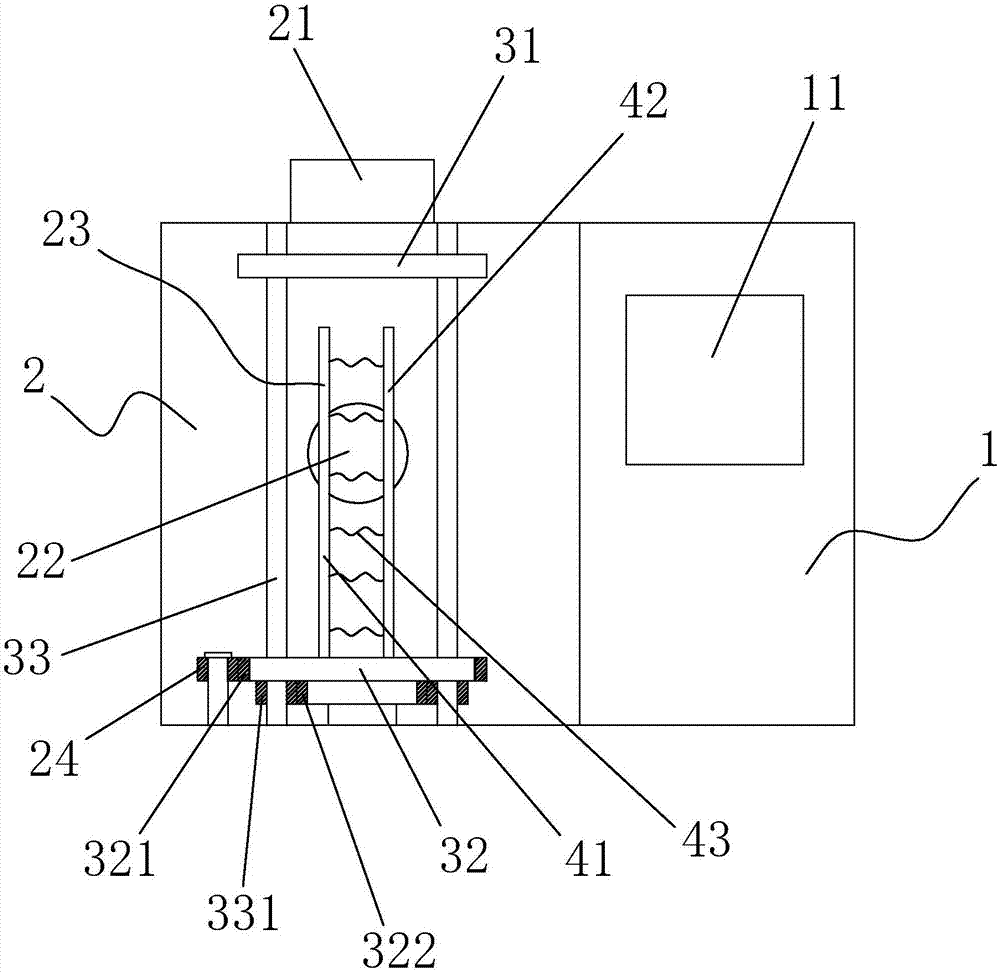

[0012] refer to figure 1 , a vacuum coating machine of the present invention, comprising a control assembly 1 and a vacuum chamber 2, a vacuum pump 21 for vacuumizing the vacuum chamber 2, a vacuum pump 21 for injecting metal vapor into the vacuum chamber 2 are arranged in the vacuum chamber 2 The steam output port 22 and the rotary coating device 23 for coating the small panel, the rotary coating device 23 includes a discharge assembly, a clamping assembly for driving the small panel to rotate, and a driving gear for driving the clamping assembly to rotate 24 , the clamping assembly meshes with the driving gear 24 , the clamping assembly is arranged on the periphery of the discharge assembly and rotates around the discharge assembly, and the vacuum pump 21 is connected with the control assembly 1 . Specifically, in the vacuum coating machine of the present invention, the vacuum chamber 2 can provide an effective coating environment for the coating process of small panels, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com