Method for coating nano copper with graphene

A graphene coating, nano copper technology, applied in nanotechnology, transportation and packaging, gaseous chemical plating, etc., can solve the problems of different coating thickness, incomplete reaction, high processing temperature, and achieve technical equipment and process. Simple, avoid incomplete coating, uniform thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

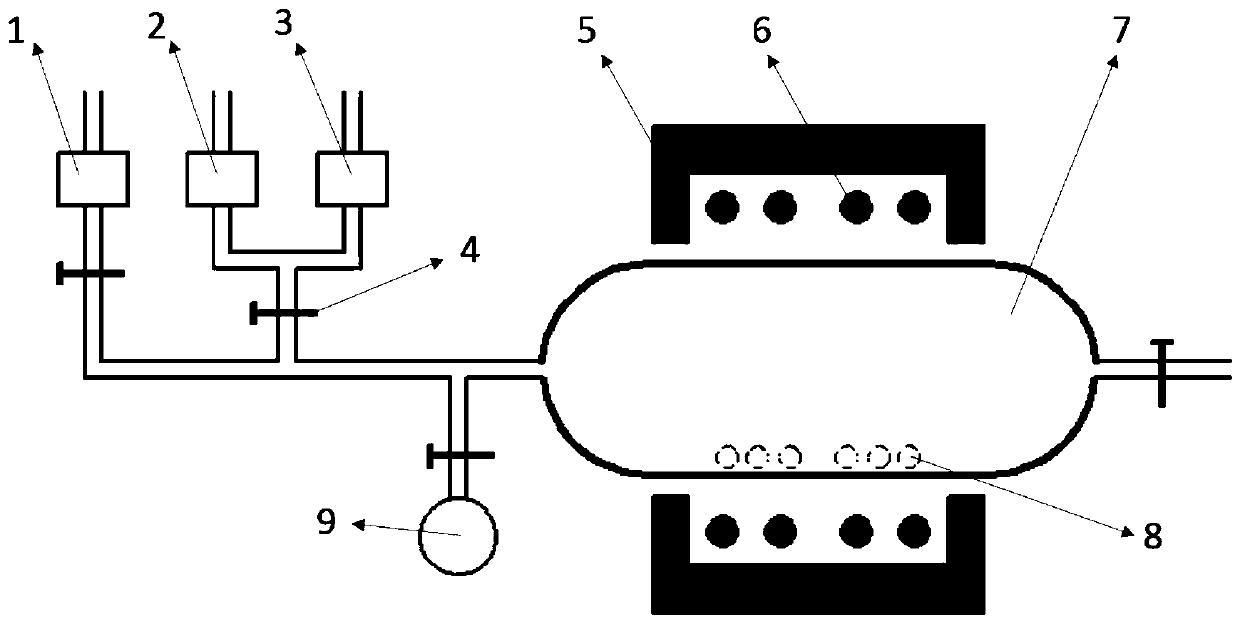

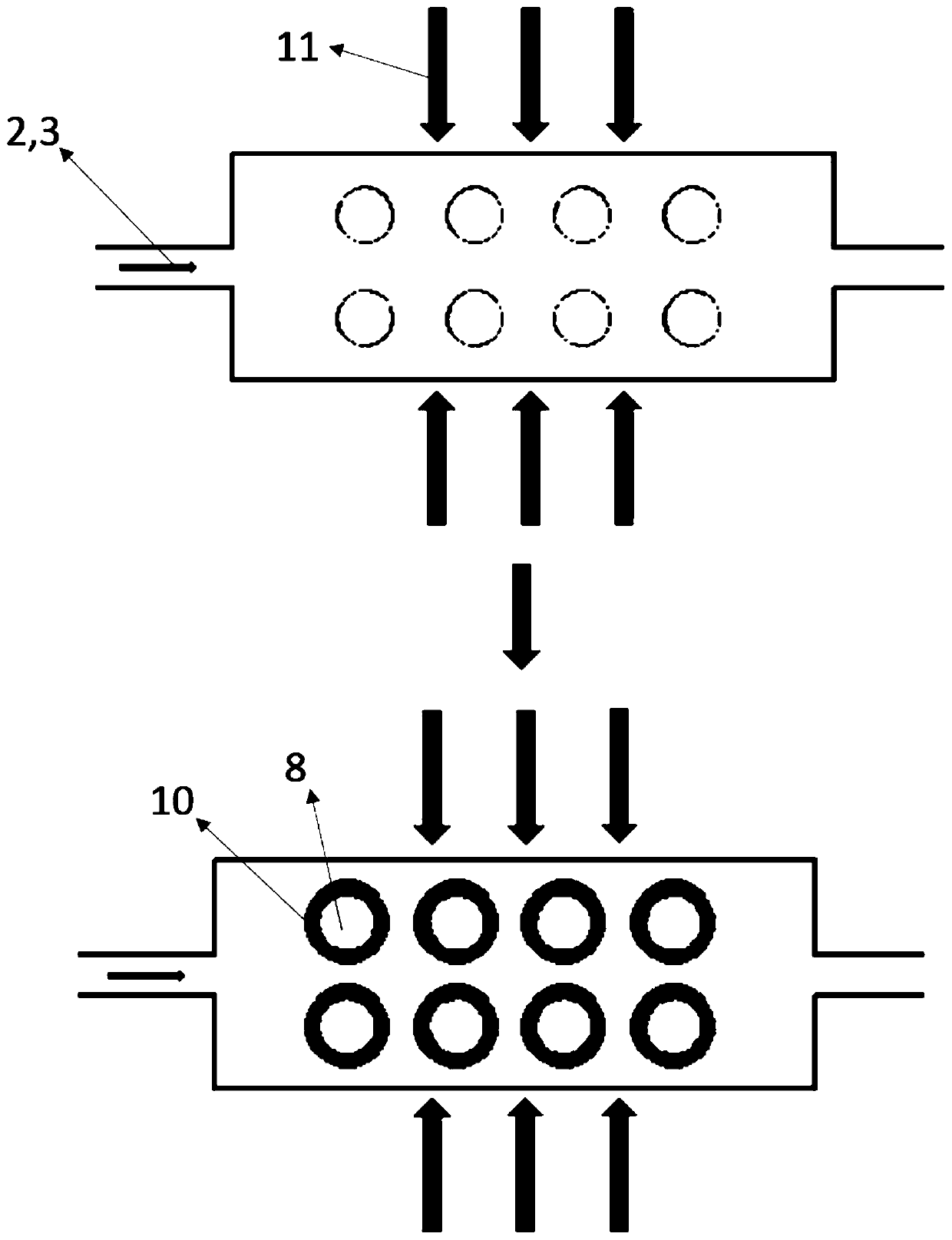

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for coating nano-copper with graphene. Before the reaction starts, the nano-copper particles are placed in an organic solvent and deionized water for three minutes with ultrasonic vibration and cleaning, and then placed in an oven with a temperature adjustment of 60 ° C to dry; then Place the dried nano-copper particles in the CVD reaction furnace, continuously feed argon gas into the CVD reaction furnace for 5 minutes, remove the air in the CVD reaction furnace, stop feeding argon gas, and start feeding a carbon source with a ratio of 1:2 Gas CH 4 and reducing gas H 2 Mixed gas, mixed gas feed rate: 0.1L / min, the reaction furnace is pumped to a low pressure of 100Pa, the reaction furnace is heated to 750°C for 0.5h, and the purpose of turning / shaking nano-copper particles is achieved by rotating the reaction furnace during the reaction deposition to ensure Nano-copper particles fully react with the mixed gas. Lower the temperature to...

Embodiment 2

[0033] This example provides another method for coating nano-copper with graphene. Before the reaction starts, the nano-copper particles are placed in an organic solvent and deionized water for three minutes with ultrasonic vibration and cleaning, and then placed in an oven with a temperature adjustment of 4 ° C to dry; then Place the dried nano-copper particles in the CVD reaction furnace, and continuously feed helium into the CVD reaction furnace for 3 minutes, remove the air in the CVD reaction furnace, stop feeding argon, and start feeding a carbon source with a ratio of 1:4 Gas CH 4 and reducing gas H 2 Mixed gas, the mixed gas feed rate: 0.05L / min, the reaction furnace is pumped to a low pressure of 150Pa, the reaction furnace is heated to 800°C for 0.2h, and the purpose of flipping / shaking the nano-copper particles is achieved by rotating the reaction furnace during the reaction deposition to ensure Nano-copper particles fully react with the mixed gas. Lower the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com