Perovskite quantum dot and preparation method and application thereof

A quantum dot and perovskite technology, which is applied in the field of titanium quantum dots and its preparation, can solve the problems of poor stability of perovskite quantum dots and low yield of perovskite quantum dots, and achieve stable solutions Poor performance, avoid incomplete coating, and controllable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

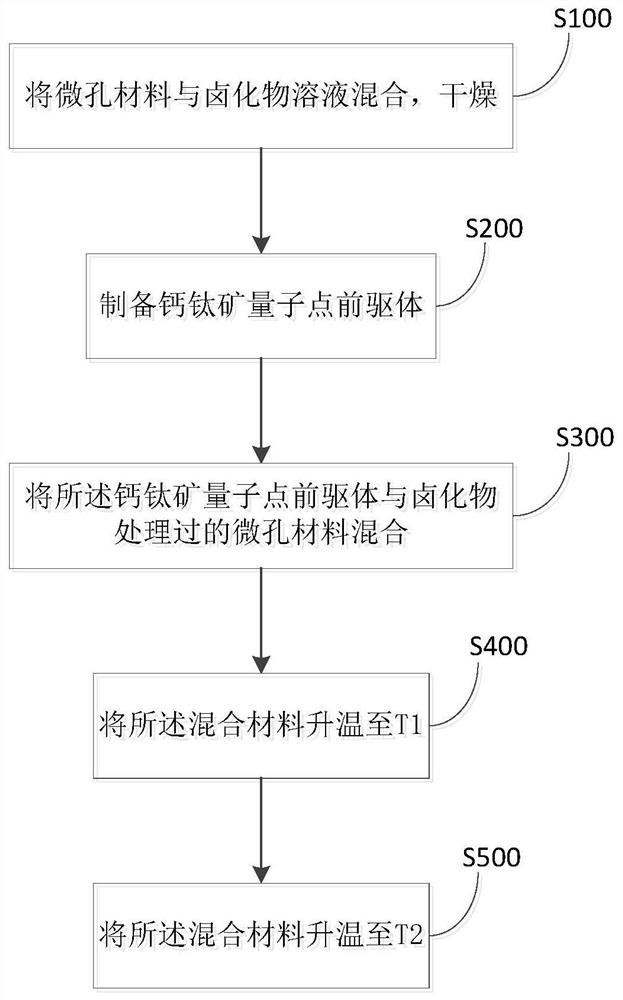

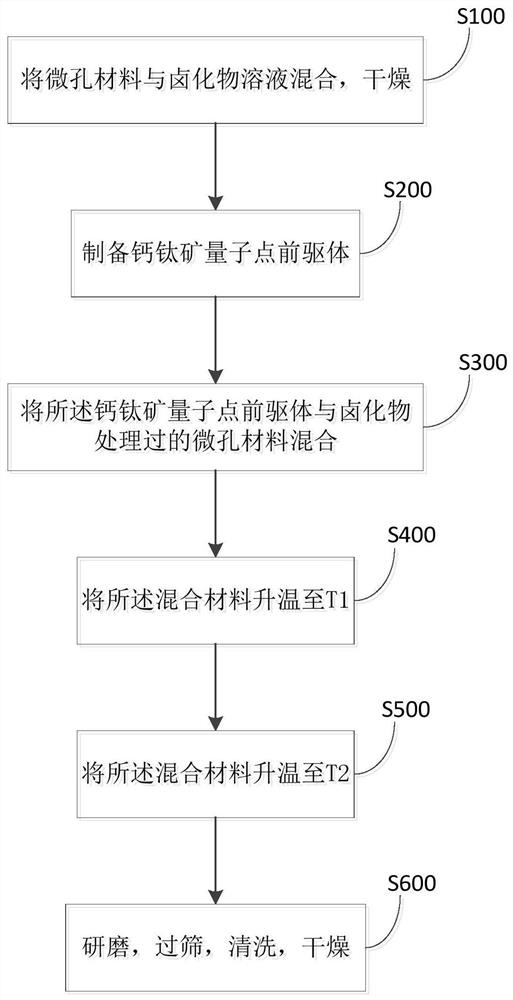

[0075] The method for preparing perovskite quantum dots according to the embodiments of the present invention has at least one of the following advantages:

[0076] 1) First, by raising the temperature T1 to not lower than the melting temperature of the perovskite quantum dot precursor and lower than the collapse temperature of the microporous material, the perovskite quantum dot precursor is melted and / or sublimated into a liquid state and / or gaseous state, so that liquid and / or gaseous perovskite quantum dot precursors enter the pores of the microporous material to deposit crystals; The perovskite crystallites are coated. The two-stage gradient temperature rise allows the perovskite to fully enter the pores of the microporous material, thereby avoiding incomplete coating of the perovskite and effectively avoiding competition with the collapse process of the microporous material. Quantum dot deposition and pore closure are carried out step by step, and the product performanc...

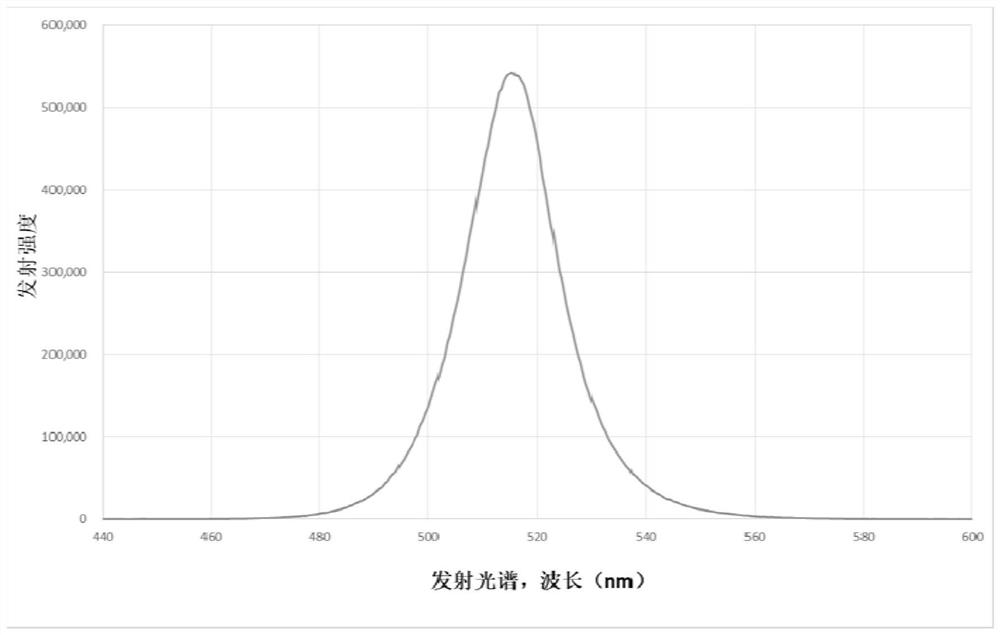

Embodiment 1

[0088] This embodiment provides a K-type CsPbBr 3 A method for preparing quantum dots, comprising the steps of:

[0089] (1) Weigh KBr and MCM-41 molecular sieve (aperture 3.7nm), add enough water into a beaker at a mass ratio of 1:1 and stir evenly, then dry to obtain the treated MCM-41 powder for later use.

[0090] (2) CsPbBr 3 Preparation of powder: Weigh 2 mmol of lead bromide and 2 mmol of cesium bromide into a round bottom flask, then add 3 ml of dimethyl sulfoxide and stir to dissolve for 30 minutes. To the above solution, 3mL of 48%wt hydrobromic acid was added dropwise, and the solution turned into an orange cloudy liquid. Centrifuge to obtain a precipitate, wash twice with isopropanol, and obtain CsPbBr 3 The powder was vacuum-dried at room temperature for later use.

[0091] (3) Weigh CsPbBr 3 The powder and the processed MCM-41 powder were mixed in a mortar at a mass ratio of 1:5, then put into a crucible and transferred to a muffle furnace.

[0092] (4) The...

Embodiment 2

[0104] This embodiment provides a kind of Na type CsPbBr 3 A method for preparing quantum dots, comprising the steps of:

[0105] (1) Weigh NaBr and SBA-15 molecular sieve (aperture 5nm), add enough water into a beaker according to the mass ratio of 3:1, stir evenly, and then dry to obtain the treated SBA-15 powder.

[0106] (2) CsPbBr 3 Preparation of powder: Weigh 2 mmol of lead bromide and 2 mmol of cesium bromide into a round bottom flask, then add 3 mL of dimethyl sulfoxide and stir to dissolve for 30 minutes. To the above solution, 3mL of 48%wt hydrobromic acid was added dropwise, and the solution turned into an orange cloudy liquid. Centrifuge to obtain a precipitate, wash twice with isopropanol, and obtain CsPbBr 3 The powder was vacuum-dried at room temperature for later use.

[0107] (3) Weigh CsPbBr 3 The powder and the processed SBA-15 powder were mixed in a mortar at a mass ratio of 1:3, then put into a crucible and transferred to a muffle furnace.

[0108] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap