A double-coated metal powder and its preparation method and application

A metal powder, double-layer coating technology, which is applied in metal processing equipment, metal material coating technology, coating, etc., can solve the problems of affecting the conductivity of conductive paste, easy migration of silver ions, and decrease in conductivity. To achieve the effect of ensuring uniform density, good protection, and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

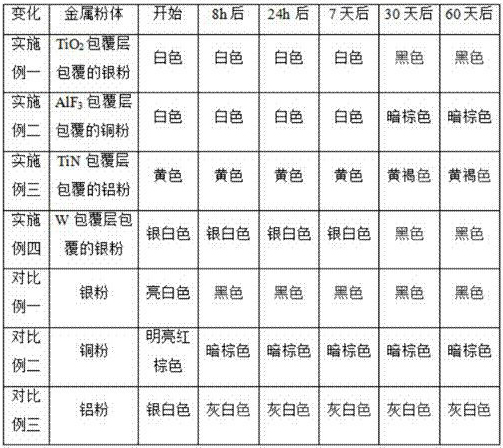

Examples

Embodiment 1

[0048] The present embodiment provides a kind of double-coated silver powder, and the surface of the silver powder is coated with TiO 2 cladding layer, TiO 2 The surface of the cladding layer is covered with a conductive carbon layer.

[0049] where TiO 2The thickness of the coating layer is 1-4nm, and the thickness of the conductive carbon layer is 1-50nm.

[0050] The present embodiment also provides the preparation method of the above-mentioned double-coated silver powder, comprising the steps of:

[0051] 1) Put the silver powder into a porous container with micropore size, place the porous container in the reaction chamber, evacuate the reaction chamber, and replace the nitrogen at least three times to remove the oxygen and water between the particles or in the pores to avoid residual react with the precursor gas; the temperature of the reaction chamber is raised to 25°C, and the pressure of the reaction chamber is maintained at 100torr;

[0052] 2) Rotate the porous ...

Embodiment 2

[0061] This embodiment provides a double-coated copper powder, the surface of the copper powder is coated with AlF 3 cladding layer, AlF 3 The surface of the cladding layer is covered with a conductive carbon layer.

[0062] where AlF 3 The thickness of the coating layer is 1-4nm, and the thickness of the conductive carbon layer is 1-50nm.

[0063] The present embodiment also provides a method for preparing the above-mentioned double-coated copper powder, comprising the following steps:

[0064] 1) Put the copper powder into a porous container with micropore size, place the porous container in the reaction chamber, evacuate the reaction chamber and replace the nitrogen at least three times, remove the oxygen and water between the particles or in the pores, and avoid The residue reacts with the precursor gas; the temperature of the reaction chamber is raised to 350°C, and the pressure of the reaction chamber is maintained at 10torr;

[0065] 2) The argon fluidization method...

Embodiment 3

[0074] This embodiment provides a double-coated aluminum powder. The surface of the aluminum powder is coated with a TiN coating layer, and the surface of the TiN coating layer is coated with a conductive carbon layer.

[0075] Wherein the thickness of the TiN cladding layer is 1-50 nm, and the thickness of the conductive carbon layer is 1-50 nm.

[0076] This embodiment also provides a method for preparing the above-mentioned double-coated aluminum powder, comprising the following steps:

[0077] 1) Put the aluminum powder into a porous container with micropore size, place the porous container in the reaction chamber, evacuate the reaction chamber and replace the nitrogen at least three times, remove the oxygen and water between the particles or in the pores, and avoid The residue reacts with the precursor gas; the temperature of the reaction chamber is raised to 150°C, and the pressure of the reaction chamber is maintained at 10torr;

[0078] 2) The argon fluidization metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com