Electrically-controlled sealing-type reducing valve for vehicle fuel gas

A sealing type, pressure reducing valve technology, applied in the field of sealing type pressure reducing valve, can solve the problems of poor sealing and prolong the service life, and achieve the effect of improving high temperature wear resistance and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

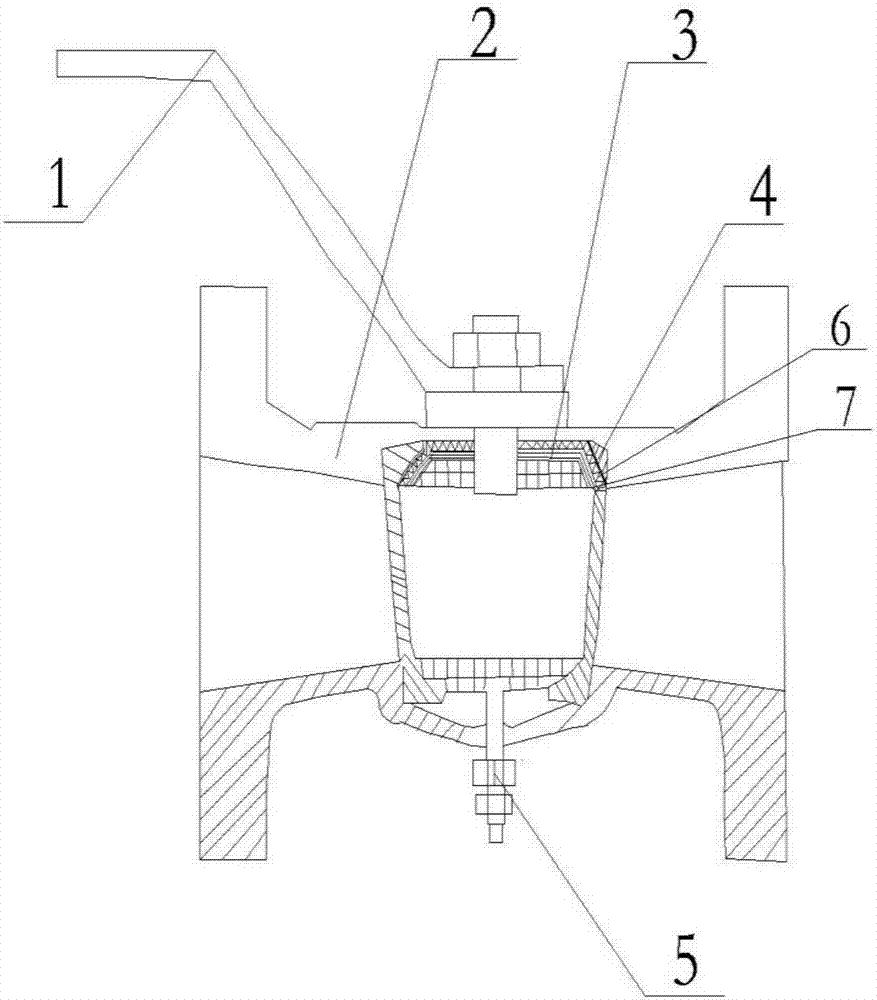

[0021] Such as figure 1 As shown, a sealed pressure reducing valve for automobile gas electric control, including a power head 1, a valve body 2, a valve core 3, an annular valve seat 4, and an adjusting screw 7, and the power head 1 is installed on the annular valve seat 4, there are two annular valve seats 4, and they are arranged oppositely. The power head 1 is installed on one of the annular valve seats 4, and a valve core 3 is installed between the two annular valve seats 4. The middle of the body 2 forms a flow channel for the flow of the liquid medium. The contact surface of the valve body 2 and the two annular valve seats 4 and the slow direction of the flange end respectively have an inclination angle of 5-10°. The two annular valve seats 4 An adjustment screw 5 is provided at the end far away from the power head 1;

[0022] A sealing ring 6 is provided between the valve core 3 and the annular valve seat 4 , and a hard cermet coating 7 is coated on the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com