Multi-fidelity design optimization method for shell structure of autonomous underwater vehicle

A technology for underwater vehicles and shell structures, applied in design optimization/simulation, instruments, calculations, etc., can solve the problems of excessive calculation, low design accuracy, and low efficiency, and achieve the effect of improving the overall accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment is a multi-fidelity design optimization method for the shell structure of an autonomous underwater vehicle.

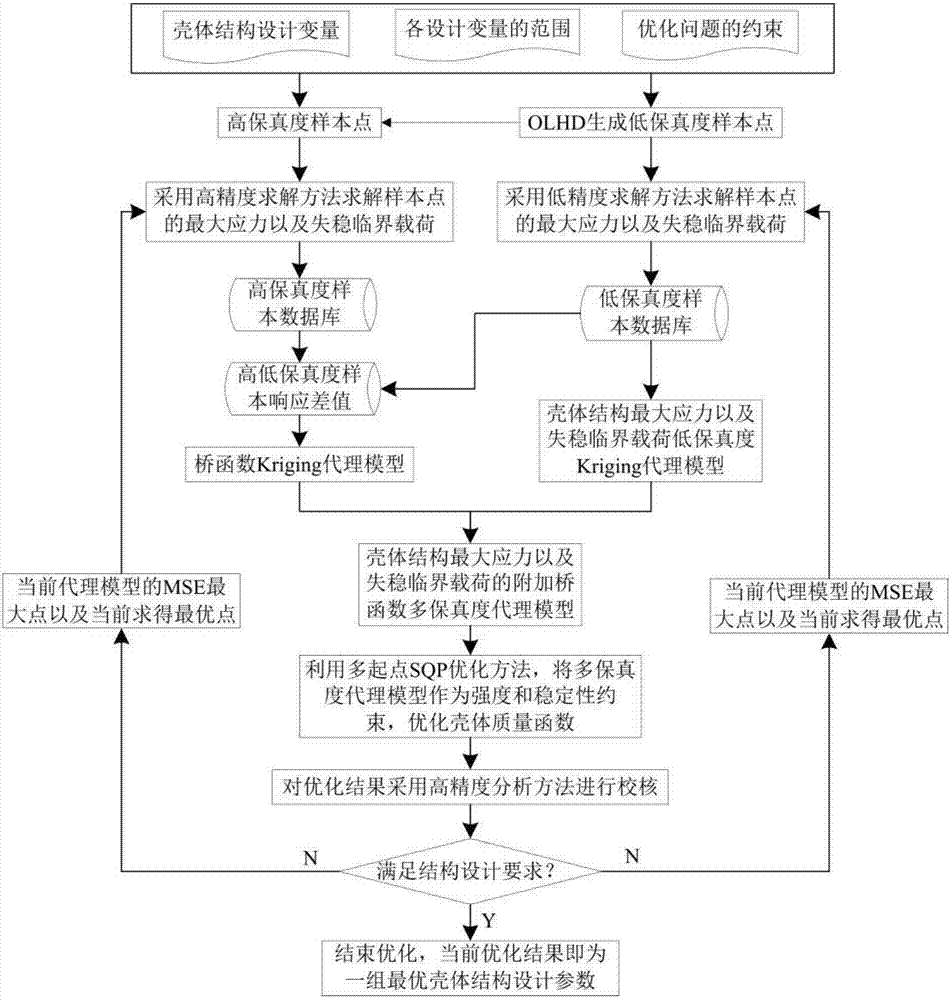

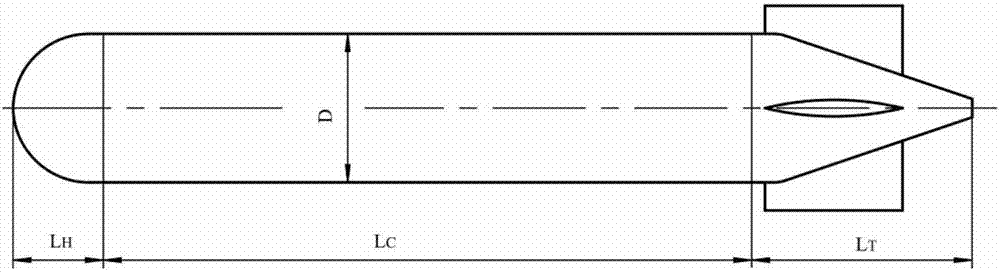

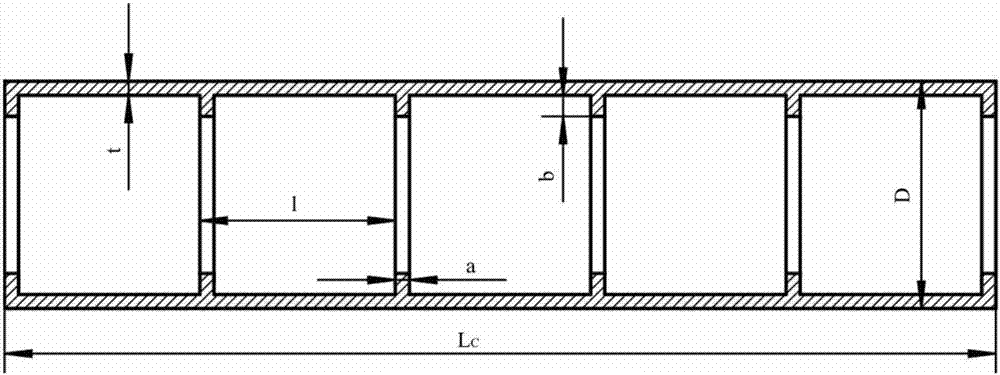

[0035] refer to figure 1 , figure 2 , image 3 , using the multi-fidelity design optimization method of the hull structure of autonomous underwater vehicles to analyze the hull of a certain type of underwater vehicle, the specific steps are as follows:

[0036] Determine the basic form of the shell structure of the underwater vehicle;

[0037] The shell structure of the underwater vehicle plays the role of bearing the load, as the support and containment of the internal equipment. Therefore, the shell structure must have sufficient strength and stability. Usually, the purpose of shell structure design optimization is to reduce its own mass, which is conducive to the carrying of more fuel or equipment. In this embodiment, the head curve segment L of the underwater vehicle H and tail curve segment L T The strength is usually higher, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com