Liquid crystal display panel driving circuit and driving method

A liquid crystal display panel and driving circuit technology, applied in static indicators, instruments, etc., can solve the problems of liquid crystal display panel burnout, excessive clock signal wiring current, short circuit, etc., and achieve the effect of avoiding false triggering of overcurrent protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

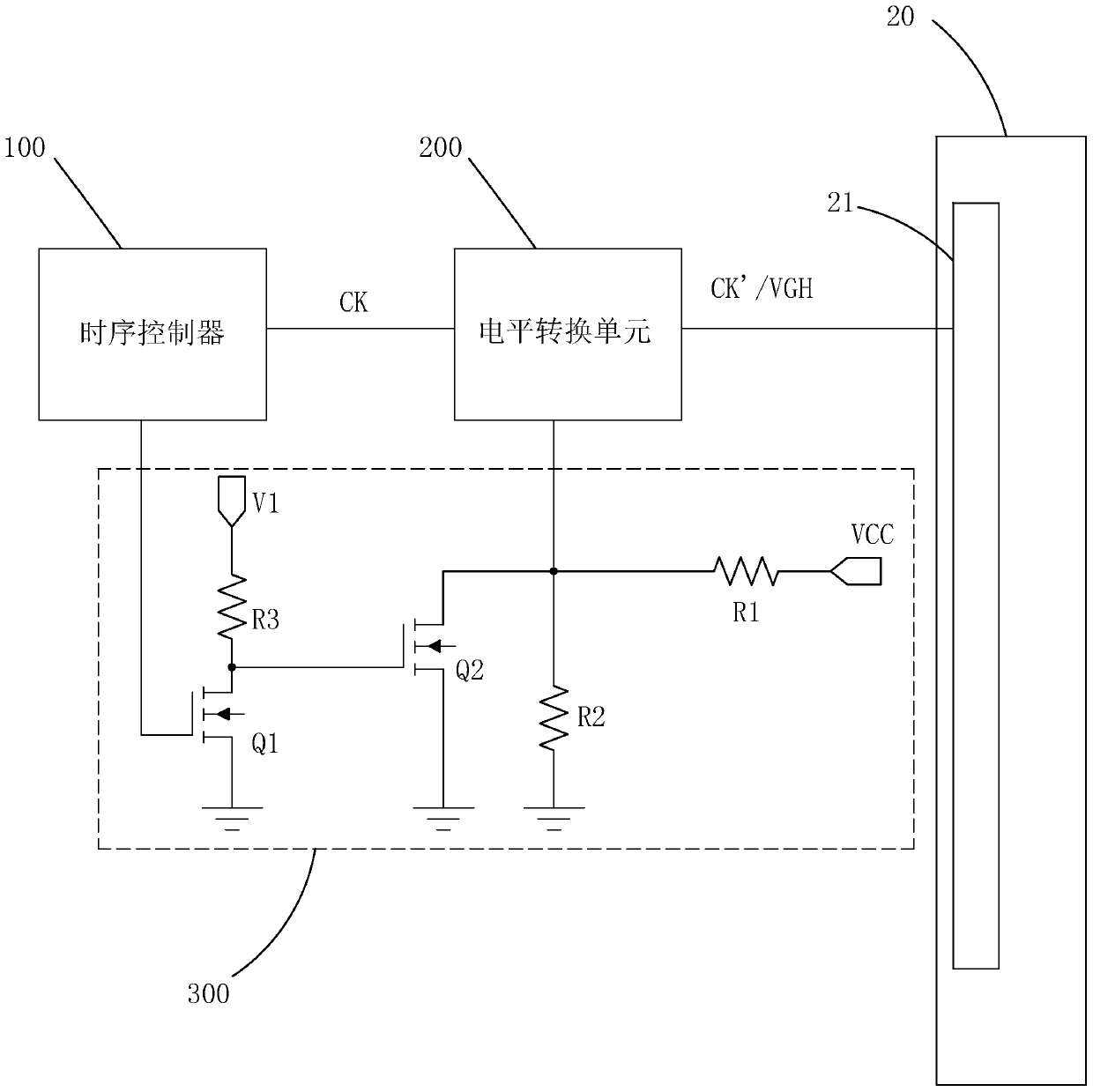

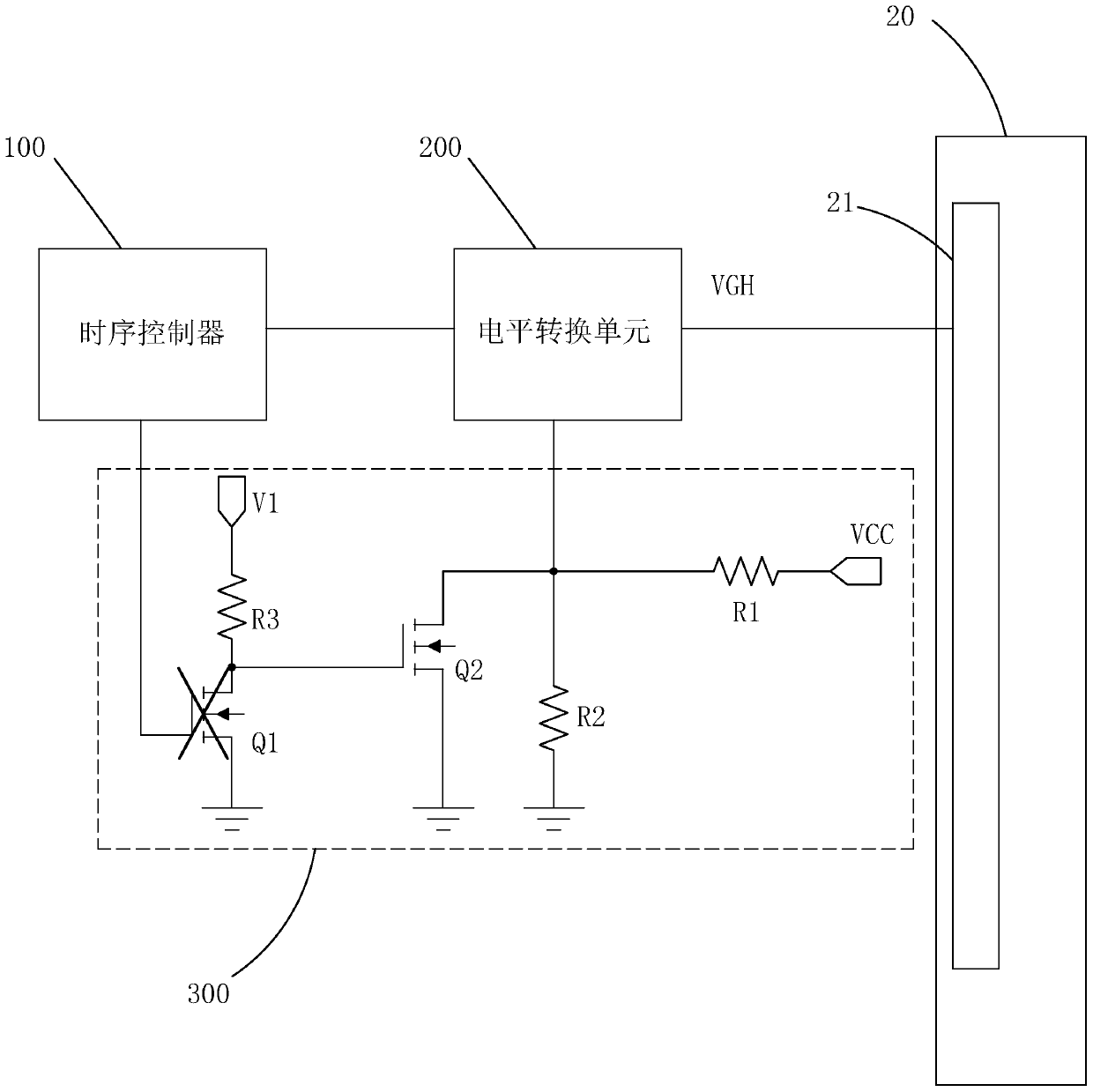

[0044] see figure 1 , the present invention provides a liquid crystal display panel driving circuit, including a timing controller 100, a level conversion unit 200 electrically connected to the timing controller 100, and a timing controller 100 and a level conversion unit 200 both an electrically connected control signal generating unit 300;

[0045] Wherein, the working mode of the liquid crystal display panel driving circuit includes a driving mode and a reset mode;

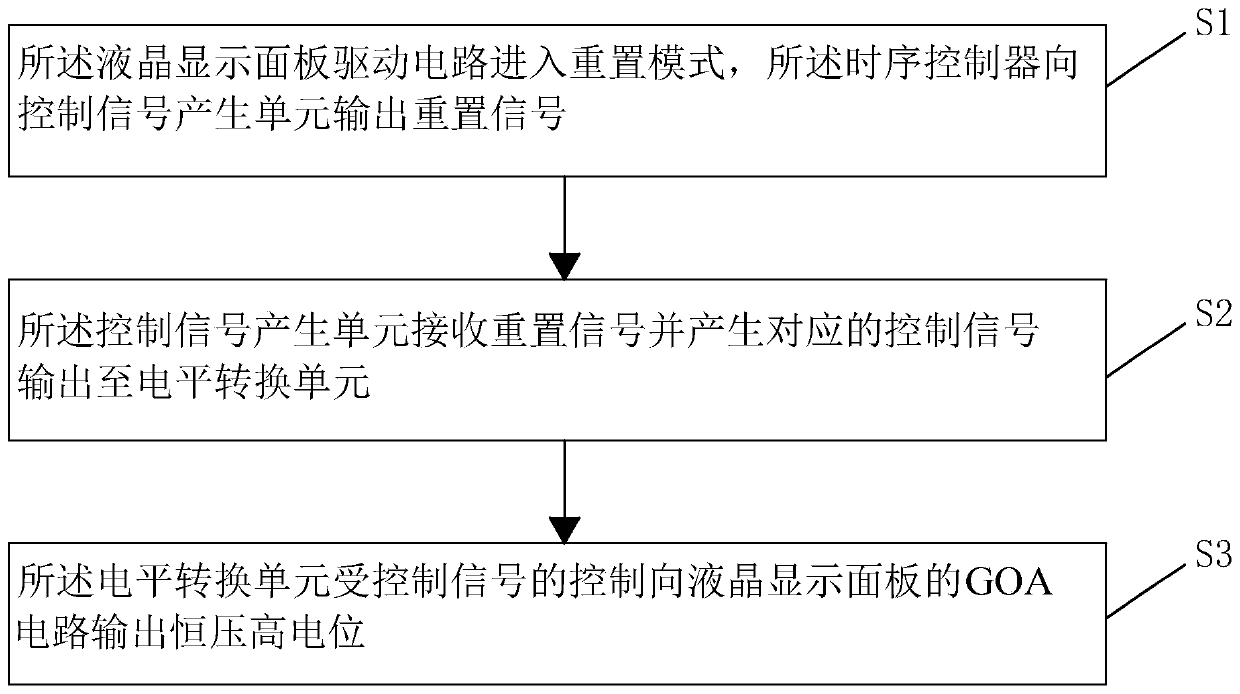

[0046] In the reset mode, the timing controller 100 outputs a reset signal to the control signal generating unit 300, and the control signal generating unit 300 receives the reset signal and generates a corresponding control signal and outputs it to the level conversion unit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com